Electronic Components Supplier | Transformers, Inductors, Inverters

PRODUCT PARAMETERS

Description

Overview of High Productivity 400KG Induction Melting Furnace Electrical Thyristor Smelting Oven for Stainless Steel Iron Copper

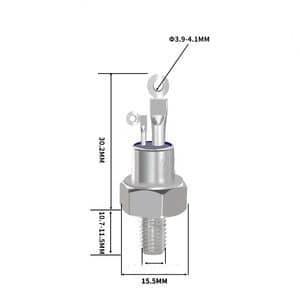

Thyristor is a solid-state semiconductor device composed of four layers of alternating P- and N-type materials. It functions as a bistable switch, conducting current only when triggered by a gate signal, and remains conducting until the voltage across it drops below a certain threshold. Thyristors are widely used for controlling high-power electrical circuits, offering efficient and reliable performance in various industrial and electronic applications.

Features of High Productivity 400KG Induction Melting Furnace Electrical Thyristor Smelting Oven for Stainless Steel Iron Copper

- High current and voltage handling capabilities

- Low on-state voltage drop, reducing power loss

- Fast switching speeds for precise control

- Latching behavior: once triggered, remains conducting without continuous gate signal

- Robust and durable design suitable for harsh environments

- Available in various types (e.g., SCR, TRIAC, GTO) for specific needs

(High Productivity 400KG Induction Melting Furnace Electrical Thyristor Smelting Oven for Stainless Steel Iron Copper)

Specifications of High Productivity 400KG Induction Melting Furnace Electrical Thyristor Smelting Oven for Stainless Steel Iron Copper

This 400KG Induction Melting Heating system thaws stainless steel, iron, copper, and similar metals quickly. It deals with 400 kilograms per set. This conserves you time. It uses electric power effectively.

The core power system is a solid-state thyristor system. Thyristors regulate the power circulation specifically. This offers stable melting efficiency. Your metal thaws continually. Power input is 250KW. The heater operates typical industrial power: 380V, 3-phase, 50Hz. It fits usual workshop configurations.

The heater body is developed difficult. Sturdy steel construction lasts long. An integrated water cooling system safeguards vital parts. Water circulates around the coil and power components. This prevents overheating. It maintains the heater running smoothly for hours. The air conditioning system is dependable.

The induction coil is copper. It’s specially made for high currents. The coil generates a strong electromagnetic field. This field warms the steel straight inside the crucible. Melting occurs swiftly. Warmth loss is marginal. You utilize much less energy.

Driver safety is very important. The heater includes several security features. Automatic closure activates if temperatures obtain too expensive. It additionally quits if water flow is low or pressure drops. These attributes avoid devices damage. They secure your employees. The control board is basic. It reveals essential details plainly. You see power levels, temperature, and system standing quickly. Beginning and stopping the melt is uncomplicated.

The crucible holds the liquified metal. It rests firmly inside the induction coil. The furnace layout allows for easy crucible adjustments. Upkeep is less complex. Downtime is decreased. This heating system boosts efficiency substantially. It melts huge sets dependably. It works well for shops and steel workshops. You get an effective, reputable melting option.

(High Productivity 400KG Induction Melting Furnace Electrical Thyristor Smelting Oven for Stainless Steel Iron Copper)

Applications of High Productivity 400KG Induction Melting Furnace Electrical Thyristor Smelting Oven for Stainless Steel Iron Copper

This 400KG induction melting furnace thaws metal fast. It handles stainless-steel, iron, and copper well. Manufacturing facilities utilize it daily. The thyristor power control is crucial. It makes heating really steady. This saves electricity also. Services see lower power costs.

Stainless steel workshops require this heating system. It thaws scrap promptly. Factories cast parts using it. The melt is tidy. Pollutants are reduced. This matters for high quality spreadings. Iron shops rely upon it. Melting iron happens quickly. Workers put mold and mildews successfully. Production maintains relocating.

Copper and brass manufacturers utilize it. Producing alloys is uncomplicated. The temperature control is exact. Copper melts uniformly. Brass mixes stay consistent. Reusing centers locate it valuable. Scrap metal develops into functional product quick. Old copper wire becomes brand-new ingots. Old stainless comes to be brand-new supply.

The 400KG size fits lots of stores. It’s not also large. It’s not also little. Workers operate it quickly. Loading steel is simple. Pouring the melt is secure. Maintenance needs are reduced. The furnace runs dependably. Downtime is minimal. Metal shops stay effective.

The power system is robust. Thyristors manage the present. Thawing cycles are quickly. Employees obtain more melts per change. Product waste is lowered. Energy usage is reliable. This furnace makes steel melting less complicated. It deals with tough jobs daily. Results are predictable. Outcome increases dramatically.

Company Profile

PDDN Photoelectron Technology Co., Ltd. is one of the leading enterprises in power electronics technology and power products, which is fully involved in developing solar inverters, transformers, voltage regulators, distribution cabinets, thyristors, modules, diodes, heaters, and other electronic devices or semiconductors. We will be committed to providing users with high-quality, efficient products and considerate service.

It accepts payment via Credit Card, T/T, West Union, and Paypal. PDDN will ship the goods to customers overseas through FedEx, DHL, by sea, or by air. If you want high-quality High Productivity 400KG Induction Melting Furnace Electrical Thyristor Smelting Oven for Stainless Steel Iron Copper, please send us inquiries; we will be here to help you.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

Storage Conditions

1) Store in a dry environment at room temperature.

2) Avoid damp and high temperature.

3) Use immediately after opening the inner packing bag.

5 FAQs of High Productivity 400KG Induction Melting Furnace Electrical Thyristor Smelting Oven for Stainless Steel Iron Copper

This furnace melts 400kg per batch. This suits small foundries. It handles stainless steel well. Iron melts easily too. Copper melts effectively also. Different metals need different settings. Operators adjust the power.

Power comes from the electrical grid. The thyristor system controls it precisely. This saves energy. Stable power means better melting. Consistent temperature is key. Metal quality improves. The system responds fast. Power fluctuations cause problems. This control prevents that.

Melting speed is important. This furnace melts 400kg of iron fast. Expect under 60 minutes. Copper melts quicker. Stainless steel takes longer sometimes. Charge size affects time. Scrap metal size matters. Clean metal melts faster. Operators learn the best ways.

The furnace is built tough. The crucible lining handles high heat. Regular checks are needed. Operators inspect linings daily. Replace linings when worn. Cooling systems prevent overheating. Electrical parts need protection. Good maintenance prevents breakdowns. Follow the schedule exactly.

Safety is critical. Operators wear protective gear. High voltage areas are shielded. The furnace has emergency stops. It shuts off automatically sometimes. Overheating triggers a shutdown. Coolant leaks stop operation. Training prevents accidents. Never bypass safety features. Keep the area clear.

(High Productivity 400KG Induction Melting Furnace Electrical Thyristor Smelting Oven for Stainless Steel Iron Copper)

REQUEST A QUOTE

RELATED PRODUCTS

Three Phase Series Choke Power Capacitor Dc Harmonic Filter Reactor 50kvar For Inverter

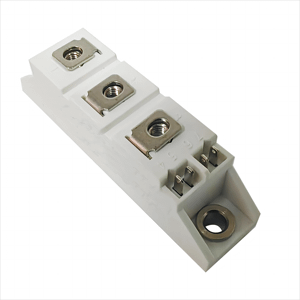

High Voltage Thyristor Control SCR kp1000A 1600V

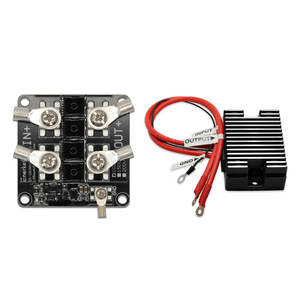

High Efficiency Thyristor Power Regulator Wide Input Range Stabilizer Whole AC Current Three Phase

4000W AC220V Electronic Voltage Regulator AC Stabilizer with Thyristor SCR for Temperature Speed Luminosity Control

Disc type SCR / phase control thyristor / fast thyristor