Electronic Components Supplier | Transformers, Inductors, Inverters

PRODUCT PARAMETERS

Description

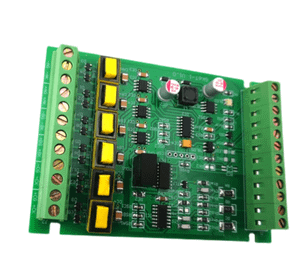

Overview of Regulator for Controlled Rectifier Circuit Thyristor Manufacturing Wind Generators and Resistance Welders Companies

Thyristor is a solid-state semiconductor device composed of four layers of alternating P- and N-type materials. It functions as a bistable switch, conducting current only when triggered by a gate signal, and remains conducting until the voltage across it drops below a certain threshold. Thyristors are widely used for controlling high-power electrical circuits, offering efficient and reliable performance in various industrial and electronic applications.

Features of Regulator for Controlled Rectifier Circuit Thyristor Manufacturing Wind Generators and Resistance Welders Companies

- High current and voltage handling capabilities

- Low on-state voltage drop, reducing power loss

- Fast switching speeds for precise control

- Latching behavior: once triggered, remains conducting without continuous gate signal

- Robust and durable design suitable for harsh environments

- Available in various types (e.g., SCR, TRIAC, GTO) for specific needs

(Regulator for Controlled Rectifier Circuit Thyristor Manufacturing Wind Generators and Resistance Welders Companies)

Specifications of Regulator for Controlled Rectifier Circuit Thyristor Manufacturing Wind Generators and Resistance Welders Companies

These regulators control power flow in thyristor circuits. They are vital for wind generators and resistance welder companies. Accurate specifications make certain trusted operation. Voltage scores come first. They have to match the system voltage. Typical levels are 480VAC or 690VAC for wind. Industrial welders commonly make use of 220VAC or 380VAC. Greater voltage variations exist for heavy equipment. Current ability is crucial. Wind generator regulatory authorities handle numerous amps. Resistance welder systems manage thousands. Confirm the constant and peak current needs. Control accuracy is essential. It affects result security. Excellent regulatory authorities keep specific voltage or present outcome. The tolerance is generally limited, like ± 1% or far better. This keeps wind power steady for the grid. It makes certain regular weld high quality. Reaction speed matters. Welding needs fast reaction times. Regulatory authorities respond in milliseconds. This stops overheating or weak welds. Wind applications need consistent control yet additionally quick mistake reaction. Protection attributes are crucial. Overvoltage and overcurrent closure shield the thyristors. Short-circuit security is mandatory. Thermal protection protects against getting too hot. Ecological specs use. Industrial setups require rugged devices. They run in broad temperature level ranges, like -25 ° C to +70 ° C. High moisture and dirt resistance prevail needs. Control signal compatibility is essential. Regulators accept typical analog inputs like 0-10VDC or 4-20mA. Digital user interfaces like Modbus or CAN bus are typically available. This permits integration with plant control systems. Physical size and installing matter. Room can be restricted. Cooling methods differ. Air cooling prevails. Water air conditioning is needed for really high power devices. Long-term dependability is non-negotiable. These components function continually. They must last for several years. Quality construction and tried and tested parts are fundamental.

(Regulator for Controlled Rectifier Circuit Thyristor Manufacturing Wind Generators and Resistance Welders Companies)

Applications of Regulator for Controlled Rectifier Circuit Thyristor Manufacturing Wind Generators and Resistance Welders Companies

Thyristor manufacturers construct regulatory authorities for controlled rectifier circuits. These regulators serve crucial roles in particular markets. Wind generator companies utilize these regulatory authorities a lot. Wind rates transform frequently. This creates unsteady power result from the turbines. The regulator fixes this problem. It regulates the thyristors specifically. The thyristors imitate quick buttons. They manage the AC power conversion right into DC power. The regulatory authority readjusts the thyristor switching timing. This smooths the DC voltage output. Secure DC voltage is critical. It shields sensitive tools better down the line. It also makes feeding power into the electrical grid reliable. Regular power means better performance for the wind farm on the whole.

Resistance welder firms likewise depend upon these regulatory authorities. Resistance welding needs specific heat control. The warmth comes from electrical present travelling through the steel components. Insufficient current makes a weak weld. Excessive current damages the parts or the welding electrodes. The regulatory authority provides the required control. It manages the thyristors in the rectifier circuit. This directly sets the welding existing degree. The regulator ensures the exact current circulations for the exact time required. This precision is essential. It develops solid, constant welds every single time. It likewise expands the life of the costly welding electrodes. Excellent control saves money and boosts item top quality. Makers obtain trustworthy performance from their welding equipments.

Company Profile

PDDN Photoelectron Technology Co., Ltd. is one of the leading enterprises in power electronics technology and power products, which is fully involved in developing solar inverters, transformers, voltage regulators, distribution cabinets, thyristors, modules, diodes, heaters, and other electronic devices or semiconductors. We will be committed to providing users with high-quality, efficient products and considerate service.

It accepts payment via Credit Card, T/T, West Union, and Paypal. PDDN will ship the goods to customers overseas through FedEx, DHL, by sea, or by air. If you want high-quality Regulator for Controlled Rectifier Circuit Thyristor Manufacturing Wind Generators and Resistance Welders Companies, please send us inquiries; we will be here to help you.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

Storage Conditions

1) Store in a dry environment at room temperature.

2) Avoid damp and high temperature.

3) Use immediately after opening the inner packing bag.

5 FAQs of Regulator for Controlled Rectifier Circuit Thyristor Manufacturing Wind Generators and Resistance Welders Companies

Regulator for Controlled Rectifier Circuit Thyristor FAQs – Wind Generators and Resistance Welders

Companies using thyristor regulators in wind generators or resistance welders often ask these questions.

What makes your thyristor regulators reliable? Our regulators use high-quality components. They undergo strict testing. This ensures they handle tough industrial conditions. Wind generator voltage fluctuations are managed effectively. Resistance welder power control becomes precise.

Can regulators be customized? Yes, customization is possible. We understand different applications need different setups. Wind generator requirements vary. Resistance welder setups are unique. We adjust regulator parameters to match your specific equipment. This guarantees optimal performance.

What technical support do you offer? We provide strong technical support. Our engineers know thyristor regulators well. They help with installation questions. They help with troubleshooting issues. They help with ongoing maintenance advice. Fast response times are important to us.

Are safety features included? Safety is a priority. Our regulators have built-in protection circuits. These prevent overloads. They prevent short circuits. They prevent overheating. This protects your valuable equipment. It protects your personnel too.

Which industries use these regulators? Our regulators serve many industries. Wind energy companies rely on them for stable power conversion. Resistance welding manufacturers need them for exact power delivery. Any application needing controlled thyristor rectification benefits.

(Regulator for Controlled Rectifier Circuit Thyristor Manufacturing Wind Generators and Resistance Welders Companies)

REQUEST A QUOTE

RELATED PRODUCTS

200A 300V Thyristor Rectifier Use for Electrophoresis

thyristor Control Board Ir thyristor Bridge Rectifier IRKT106/14

High-power thyristor speed control, temperature control, dimming controller 4000W thyristor regulator

High Efficiency Thyristor Power Regulator Wide Input Range Stabilizer Whole AC Current Three Phase

High Quality Low Voltage Dynamic Regulator Power Factor Controller Thyristor Switch Manufactured by High Quality Stabilizers