Electronic Components Supplier | Transformers, Inductors, Inverters

PRODUCT PARAMETERS

Description

Overview of Thyristor Carbon Arc Air Gouging Welder Industrial Welding Machine for Groove Preparation

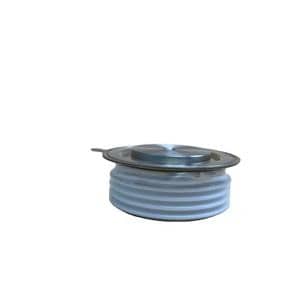

Thyristor is a solid-state semiconductor device composed of four layers of alternating P- and N-type materials. It functions as a bistable switch, conducting current only when triggered by a gate signal, and remains conducting until the voltage across it drops below a certain threshold. Thyristors are widely used for controlling high-power electrical circuits, offering efficient and reliable performance in various industrial and electronic applications.

Features of Thyristor Carbon Arc Air Gouging Welder Industrial Welding Machine for Groove Preparation

- High current and voltage handling capabilities

- Low on-state voltage drop, reducing power loss

- Fast switching speeds for precise control

- Latching behavior: once triggered, remains conducting without continuous gate signal

- Robust and durable design suitable for harsh environments

- Available in various types (e.g., SCR, TRIAC, GTO) for specific needs

(Thyristor Carbon Arc Air Gouging Welder Industrial Welding Machine for Groove Preparation)

Specifications of Thyristor Carbon Arc Air Gouging Welder Industrial Welding Machine for Groove Preparation

This industrial welding maker handles groove preparation job. Groove preparation suggests reducing channels in metal surface areas. This device uses carbon arc air gouging for this job. Carbon arc air gouging removes metal fast. It makes use of a carbon electrode. This electrode creates an intense electric arc. The arc melts the steel. Pressed air blows the liquified metal away. This leaves a clean groove. The groove is ready for welding.

The maker features thyristor control. Thyristor control provides stable arc performance. You manage the warmth outcome really specifically. This control is essential for consistent gouging outcomes. It prevents damaging or irregular grooves. The equipment deals with laborious. It works on thick steel plates. It removes weld problems effectively. It prepares bevel sides for pipeline welding. It reduces steel without requiring an oxy-fuel arrangement.

Power outcome is flexible. You set the amperage to match the job. Normal variety is 200 Amps to 1600 Amps. Greater amperage eliminates even more steel much faster. Obligation cycle is very important. This machine uses a high responsibility cycle. A 60% task cycle at maximum load prevails. This implies it runs 6 minutes every 10 mins. It takes care of constant workshop usage. Input power is normally 380V, 3-phase, 50Hz. This offers the essential strong current.

The equipment consists of an air compressor. The compressor materials high-pressure air. Atmospheric pressure is flexible. You set the stress for the electrode size and metal kind. Usual pressure is 80-100 PSI. The device is built tough. It has a strong steel structure. It commonly has wheels for moving the shop. Overload defense keeps it secure. Thermal protection avoids overheating. It works accurately in demanding commercial setups. Ports link the airline and gouging lantern. Procedure is straightforward after configuration.

(Thyristor Carbon Arc Air Gouging Welder Industrial Welding Machine for Groove Preparation)

Applications of Thyristor Carbon Arc Air Gouging Welder Industrial Welding Machine for Groove Preparation

This maker gouges metal fast. It utilizes electrical energy and compressed air. A carbon electrode produces a high warm arc. The air blast blows away the thawed steel. This makes a groove. Groove preparation is crucial for good welding. Welders require tidy, shaped grooves. This maker creates those grooves efficiently.

It eliminates unwanted steel quickly. Assume old welds, issues, or cracks. It cuts through thick steel conveniently. Operators manage the depth and size. This is crucial for appropriate groove forms. The maker prepares surface areas before welding. It cleans harmed locations. It shapes the sides for the weld joint. This makes certain strong, reputable welds later.

The thyristor control is necessary. It offers stable, flexible power. Operators established the existing exactly. This matches various work and steel densities. Constant power implies smooth gouging. It avoids issues like unequal grooves. The device handles laborious well. It services large frameworks like ships or bridges. It gets rid of huge areas of steel quick. This saves substantial time and money.

It’s really portable. Employees move it around the shop or website quickly. Configuration is straightforward. Operators discover to utilize it promptly. Maintenance is easy. The process is really visual. Operators see the groove developing plainly. They change their method promptly. It’s effective on many metals. Steel, stainless steel, cast iron are common targets. It gets rid of bolts or rivets quickly. It cuts access holes in plates. It prepares pipeline ends for welding. It cleans back sides of welds. The machine is an effective device. It fixes numerous metal removal problems. It finishes the job reliably.

Company Profile

PDDN Photoelectron Technology Co., Ltd. is one of the leading enterprises in power electronics technology and power products, which is fully involved in developing solar inverters, transformers, voltage regulators, distribution cabinets, thyristors, modules, diodes, heaters, and other electronic devices or semiconductors. We will be committed to providing users with high-quality, efficient products and considerate service.

It accepts payment via Credit Card, T/T, West Union, and Paypal. PDDN will ship the goods to customers overseas through FedEx, DHL, by sea, or by air. If you want high-quality Thyristor Carbon Arc Air Gouging Welder Industrial Welding Machine for Groove Preparation, please send us inquiries; we will be here to help you.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

Storage Conditions

1) Store in a dry environment at room temperature.

2) Avoid damp and high temperature.

3) Use immediately after opening the inner packing bag.

5 FAQs of Thyristor Carbon Arc Air Gouging Welder Industrial Welding Machine for Groove Preparation

What does this machine do?

It prepares metal surfaces. The machine gouges grooves. It removes bad welds. It cuts defects out. It cleans metal joints. It makes metal ready for new welding.

How does it work?

It uses electricity and air. A carbon rod touches the metal. This creates an electric arc. The arc heats the metal intensely. Compressed air blows the melted metal away. This leaves a clean groove.

Why use carbon arc air gouging?

It is fast. It removes metal efficiently. It works on thick metal. It provides deep grooves. It is cheaper than other methods sometimes. It gives good access to tight spaces.

Where is it used?

It is used in heavy industry. Shipyards use it. Construction sites use it. Repair shops use it. Factories use it. It prepares metal plates and structures. It removes old welds on bridges and pipelines.

What safety is needed?

Operators need strong protection. Wear a welding helmet with a dark lens. Use heavy gloves. Wear fire-resistant clothing. Ear protection is vital. Good ventilation is essential. The process is loud and creates sparks and hot metal.

(Thyristor Carbon Arc Air Gouging Welder Industrial Welding Machine for Groove Preparation)

REQUEST A QUOTE

RELATED PRODUCTS

Disc type KP series ordinary phase control thyristor / scr thyristor

Russian stud Thyristors Symmetrical Thyristors TC152-160-14 TS152-160 Stud Triacs 10A – 160A

High Voltage Thyristor Control SCR kp1000A 1600V

Phase control thyristor SCR 50 amp scr 50ria120 power thyristor 50ria120scr MEDIUM POWER THYRISTORS

TECH SEMICONDUCTORS SCR Thyristor for induction furnace power supply