Electronic Components Supplier | Transformers, Inductors, Inverters

PRODUCT PARAMETERS

Description

Overview of Electric Induction Furnace Medium Frequency Copper Scrap Melting Induction Furnace

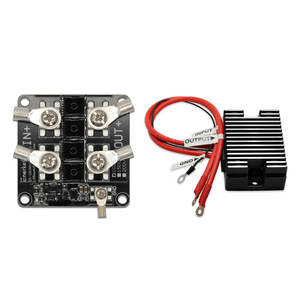

Thyristor is a solid-state semiconductor device composed of four layers of alternating P- and N-type materials. It functions as a bistable switch, conducting current only when triggered by a gate signal, and remains conducting until the voltage across it drops below a certain threshold. Thyristors are widely used for controlling high-power electrical circuits, offering efficient and reliable performance in various industrial and electronic applications.

Features of Electric Induction Furnace Medium Frequency Copper Scrap Melting Induction Furnace

- High current and voltage handling capabilities

- Low on-state voltage drop, reducing power loss

- Fast switching speeds for precise control

- Latching behavior: once triggered, remains conducting without continuous gate signal

- Robust and durable design suitable for harsh environments

- Available in various types (e.g., SCR, TRIAC, GTO) for specific needs

(Electric Induction Furnace Medium Frequency Copper Scrap Melting Induction Furnace)

Specifications of Electric Induction Furnace Medium Frequency Copper Scrap Melting Induction Furnace

This Electric Induction Furnace melts copper scrap fast. It uses medium frequency power. The furnace handles many types of scrap. Think waste wire, pipes, and other copper leftovers. It turns scrap into liquid copper ready for casting. This process is efficient and clean.

Power ratings range widely. Options go from 150 kW to over 2500 kW. Crucible capacity varies too. Furnaces hold 500kg up to 8 tons of copper. Melting speed depends on size and power. A full crucible melts in roughly 40 to 60 minutes. The furnace achieves high thermal efficiency. Expect around 98% efficiency. This saves significant energy and lowers running costs.

The core component is the induction coil. It generates the intense magnetic field. This field directly heats the metal inside the crucible. Crucibles come in steel shells. They have advanced refractory linings inside. Common lining materials are quartzite or magnesia. These linings resist extreme heat and chemical wear. Crucible life depends on careful operation and maintenance. Check linings regularly.

A strong steel structure supports the whole furnace. It includes a sturdy tilting mechanism. Operators tilt the furnace to pour molten copper. Safety is critical. The furnace has water cooling systems. These cool the coil, capacitors, and power connections. Reliable cooling prevents overheating damage. An electrical cabinet houses the power supply and controls. Modern control panels are user-friendly. Operators set parameters and monitor the melt cycle easily.

This furnace design minimizes noise. It also reduces heat radiation into the shop. Operating costs are manageable. Power consumption is key. Refractory replacement adds to expenses. Proper maintenance extends component life. The furnace needs a solid foundation. Ensure adequate electrical supply and cooling water connections. Training operators is essential for safe, efficient use.

(Electric Induction Furnace Medium Frequency Copper Scrap Melting Induction Furnace)

Applications of Electric Induction Furnace Medium Frequency Copper Scrap Melting Induction Furnace

Electric induction furnaces melt copper scrap efficiently. Medium frequency models are popular for this job. These furnaces use electromagnetic induction. A power source creates alternating current. This current flows through a copper coil. The coil surrounds the crucible holding the scrap. The changing magnetic field induces currents inside the scrap metal itself. These currents generate heat directly within the copper. The heat melts the scrap fast.

This method offers big advantages. It’s very energy efficient. Heat forms inside the metal. Less heat escapes compared to older furnace types. Operators get precise temperature control. They can manage the melt exactly. This is vital for quality copper production. The melting process stays clean. No combustion gases mix with the metal. This keeps the copper pure. It also makes the workplace safer.

These furnaces handle copper scrap well. They melt all sorts of shapes. Bus bars, wire chunks, and turnings are no problem. The furnace starts and stops quickly. Operators can pour the molten copper easily. Then they can reload scrap fast. This saves time and boosts productivity. Maintaining the furnace is simple. The main parts needing attention are the coil lining and the crucible.

Factories use these furnaces for recycling. Foundries use them to make new copper products. They are essential for melting scrap copper effectively. The furnace recovers valuable metal from waste. This saves money and resources. The process is reliable and consistent. It delivers high-quality molten copper every time. Businesses rely on it for smooth operations.

Company Profile

PDDN Photoelectron Technology Co., Ltd. is one of the leading enterprises in power electronics technology and power products, which is fully involved in developing solar inverters, transformers, voltage regulators, distribution cabinets, thyristors, modules, diodes, heaters, and other electronic devices or semiconductors. We will be committed to providing users with high-quality, efficient products and considerate service.

It accepts payment via Credit Card, T/T, West Union, and Paypal. PDDN will ship the goods to customers overseas through FedEx, DHL, by sea, or by air. If you want high-quality Electric Induction Furnace Medium Frequency Copper Scrap Melting Induction Furnace, please send us inquiries; we will be here to help you.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

Storage Conditions

1) Store in a dry environment at room temperature.

2) Avoid damp and high temperature.

3) Use immediately after opening the inner packing bag.

5 FAQs of Electric Induction Furnace Medium Frequency Copper Scrap Melting Induction Furnace

How does this furnace melt copper?

It uses magnetic fields. Electricity creates these fields inside the furnace coil. The fields heat the copper scrap directly. The copper melts fast. You get liquid copper ready for pouring.

Is it energy efficient?

Yes, very efficient. Induction heating targets only the metal. Less heat escapes. Your power bill drops. You save money melting copper scrap.

What copper scrap works?

It handles most common copper types. Clean wire, bus bars, and chopped tubing melt well. Avoid scrap with too much iron or other junk metals. Cleaner scrap gives better results.

Is operation safe?

Safety features are built in. Water cooling prevents overheating. The furnace body stays cooler. The system monitors temperature precisely. Operators stay safer.

How much maintenance is needed?

Maintenance is mostly simple checks. Look at the crucible lining often. Replace it when worn down. Check water cooling lines regularly. Keep electrical connections tight.

(Electric Induction Furnace Medium Frequency Copper Scrap Melting Induction Furnace)

REQUEST A QUOTE

RELATED PRODUCTS

Three-phase Thyristor Switches Dynamic Thyristor Switches Capacitor Quick-throw Switches

High Efficiency Thyristor Power Regulator Wide Input Range Stabilizer Whole AC Current Three Phase

200A 300V Thyristor Rectifier Use for Electrophoresis

Reactive Power Compensation Device Used in Power System Improve Power Factor

thyristor power controller scr power thyristor discrete thyristor