Electronic Components Supplier | Transformers, Inductors, Inverters

PRODUCT PARAMETERS

Description

Overview of 1T 800KW Aluminum Shell Melting Induction Furnace for for Metal Foundry

Thyristor is a solid-state semiconductor device composed of four layers of alternating P- and N-type materials. It functions as a bistable switch, conducting current only when triggered by a gate signal, and remains conducting until the voltage across it drops below a certain threshold. Thyristors are widely used for controlling high-power electrical circuits, offering efficient and reliable performance in various industrial and electronic applications.

Features of 1T 800KW Aluminum Shell Melting Induction Furnace for for Metal Foundry

- High current and voltage handling capabilities

- Low on-state voltage drop, reducing power loss

- Fast switching speeds for precise control

- Latching behavior: once triggered, remains conducting without continuous gate signal

- Robust and durable design suitable for harsh environments

- Available in various types (e.g., SCR, TRIAC, GTO) for specific needs

(1T 800KW Aluminum Shell Melting Induction Furnace for for Metal Foundry)

Specifications of 1T 800KW Aluminum Shell Melting Induction Furnace for for Metal Foundry

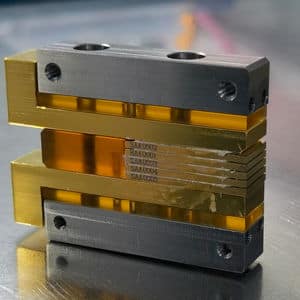

This 1-ton, 800KW aluminum covering melting induction heating system melts metal quickly for factories. It utilizes solid electric power to create warmth inside steel. The main external structure is aluminum. Aluminum is tough. It handles the warmth well. It safeguards the heater inside. The heater stands up to 1 ton of metal. Usual steels are light weight aluminum, copper, brass, sometimes steel. The 800KW power thaws steel rapidly. Melting times depend upon the steel type. Expect quick melting cycles.

The heater style focuses on effective heating. Effective copper coils create the melting area. Water cooling keeps these coils risk-free. The system requires good water flow. A special lining shields the heater crucible. This lining withstands severe temperatures. Crucible life is necessary. Operators needs to mount the lining appropriately. Appropriate installment stays clear of troubles later.

This heater works continually. It fits requiring foundry schedules. Operators manage the melting process easily. Controls are straightforward. Monitoring power degrees is basic. Seeing the metal temperature is very easy. Security attributes are integrated. These protect drivers and equipment. The heater needs a reliable power supply. Three-phase industrial power is conventional. Water air conditioning is essential constantly.

The heating system design assists with pouring. Turning the furnace is smooth. Putting molten steel is regulated. Operators remain risk-free throughout pouring. Maintenance access is excellent. Checking components is straightforward. Replacing worn sections is manageable. The light weight aluminum shell remains cooler outside. This minimizes workshop warm. It makes the workspace more secure. This heating system is a core device for melting steel efficiently.

(1T 800KW Aluminum Shell Melting Induction Furnace for for Metal Foundry)

Applications of 1T 800KW Aluminum Shell Melting Induction Furnace for for Metal Foundry

This 1 bunch, 800KW light weight aluminum covering melting induction furnace thaws steel quickly for shops. It manages many metals well. Iron, aluminum, copper, brass, bronze, and steel alloys thaw effectively inside it. The furnace utilizes solid magnetic fields. These areas develop heat directly inside the metal charge. This technique is much faster than old gas or coal heaters. Thawing takes place rapidly, conserving useful manufacturing time.

The aluminum covering layout supplies real benefits. Light weight aluminum performs heat away from the coil successfully. This maintains the important induction coil cooler during long melting cycles. A cooler coil lasts longer and executes much better. The covering itself is difficult. It handles the demanding shop atmosphere without damage. Maintenance requirements are reduced contrasted to various other furnace types.

Factories acquire considerable benefits using this heating system. Its small size fits well in different shop formats. The fast melting speed raises total steel output. Precise temperature level control is possible. Operators can hold certain temperatures precisely for alloying or casting. Energy efficiency is a significant plus. Extra electrical power goes directly right into melting the metal. This cuts electrical power prices significantly gradually. The furnace starts melting quickly. No lengthy pre-heating delays decrease the workday.

Operational dependability is crucial. The robust design makes sure constant melting performance shift after change. Downtime for fixings is reduced. The heating system functions accurately for demanding manufacturing timetables. Employees find it simple to operate. Training needs are manageable. Security improves also. The melting procedure contains the molten steel safely inside the crucible.

Company Profile

PDDN Photoelectron Technology Co., Ltd. is one of the leading enterprises in power electronics technology and power products, which is fully involved in developing solar inverters, transformers, voltage regulators, distribution cabinets, thyristors, modules, diodes, heaters, and other electronic devices or semiconductors. We will be committed to providing users with high-quality, efficient products and considerate service.

It accepts payment via Credit Card, T/T, West Union, and Paypal. PDDN will ship the goods to customers overseas through FedEx, DHL, by sea, or by air. If you want high-quality 1T 800KW Aluminum Shell Melting Induction Furnace for for Metal Foundry, please send us inquiries; we will be here to help you.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

Storage Conditions

1) Store in a dry environment at room temperature.

2) Avoid damp and high temperature.

3) Use immediately after opening the inner packing bag.

5 FAQs of 1T 800KW Aluminum Shell Melting Induction Furnace for for Metal Foundry

Here are 5 key questions about the 1T 800KW Aluminum Shell Melting Induction Furnace for metal foundries:

What metal can this furnace melt? This 1-ton furnace melts common non-ferrous metals. It handles aluminum alloys well. It melts brass and copper effectively. It works for zinc too. The furnace design suits these materials perfectly.

How much power does it need? The furnace needs an 800KW power supply. Check your local power grid capacity first. Voltage requirements are specific. Refer to the technical specifications sheet. Proper power setup is essential for stable operation.

How fast does it melt metal? Melting speed depends on the metal type. It melts one ton of aluminum in about 45-60 minutes typically. Brass takes slightly longer. Copper melting takes more time. The 800KW power ensures efficient heating.

Is the aluminum shell strong enough? The aluminum shell is robust. It withstands high operating temperatures. Its design provides good mechanical strength. It protects the internal components reliably. The shell construction ensures furnace longevity.

What maintenance is necessary? Regular maintenance is simple. Inspect the crucible lining often. Check electrical connections periodically. Keep cooling water systems clean. Monitor the induction coil condition. Consistent upkeep prevents unexpected downtime.

(1T 800KW Aluminum Shell Melting Induction Furnace for for Metal Foundry)

REQUEST A QUOTE

RELATED PRODUCTS

Great Easy Operation Thyristor

Capsule Type Phase Control Thyristor SCR for Railway

Phase Control Thyristor SCR for High Power Converter Disc Type Phase controlled Thyristor

thyristor Control Board Ir thyristor Bridge Rectifier IRKT106/14

High Power Thyristor Electronic Voltage Regulator Motor Fan Drill Speed Regulator Temperature Regulator