Electronic Components Supplier | Transformers, Inductors, Inverters

PRODUCT PARAMETERS

Description

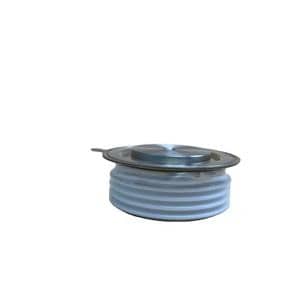

Overview of Russian phase controlled thyristor inductive thermal thyristor

Thyristor is a solid-state semiconductor device composed of four layers of alternating P- and N-type materials. It functions as a bistable switch, conducting current only when triggered by a gate signal, and remains conducting until the voltage across it drops below a certain threshold. Thyristors are widely used for controlling high-power electrical circuits, offering efficient and reliable performance in various industrial and electronic applications.

Features of Russian phase controlled thyristor inductive thermal thyristor

- High current and voltage handling capabilities

- Low on-state voltage drop, reducing power loss

- Fast switching speeds for precise control

- Latching behavior: once triggered, remains conducting without continuous gate signal

- Robust and durable design suitable for harsh environments

- Available in various types (e.g., SCR, TRIAC, GTO) for specific needs

(Russian phase controlled thyristor inductive thermal thyristor)

Specifications of Russian phase controlled thyristor inductive thermal thyristor

This Russian-made phase controlled thyristor is built tough for demanding induction heating jobs. It handles the intense heat and electrical stress common in these systems. Think big industrial furnaces or metal processing lines. This device reliably manages large amounts of power.

The thyristor blocks high voltage, typically rated up to 1600 volts. It carries substantial current, often hundreds or even thousands of amperes. This high power capacity is essential for industrial heating. The device turns on and off very fast. This precise switching is critical for phase control operation. You control exactly when power flows during each voltage cycle.

Applying a small control signal to its gate terminal triggers the thyristor into conduction. It stays on until the main current drops below a certain level. This characteristic makes it ideal for AC power control. The thyristor manages the power delivered to the induction coil effectively. Accurate timing of the gate signal is necessary for smooth operation.

Heat is a major factor. The thyristor generates significant internal heat during operation. Efficient cooling is absolutely mandatory. These devices usually mount onto large heatsinks. Sometimes forced air or liquid cooling is required. The design ensures stable performance even under thermal stress. It handles the repeated heating and cooling cycles inherent in induction applications.

Robust construction is key. The thyristor features a strong, pressure-mounted package. This design promotes good electrical contact and heat transfer. Internal components are built to endure high surge currents and voltage spikes. This durability is vital for industrial environments. Russian manufacturers emphasize reliability in harsh conditions. Long service life is a primary design goal. These thyristors need minimal maintenance when used correctly. They provide dependable power control for demanding thermal processes.

(Russian phase controlled thyristor inductive thermal thyristor)

Applications of Russian phase controlled thyristor inductive thermal thyristor

Russian phase controlled thyristors handle tough jobs. They manage big power in induction heating systems. These systems heat metal fast using magnetic fields. The thyristors act like super strong switches. They control the huge electrical currents needed. Precise control is vital. It keeps the heating consistent.

These thyristors are built strong. They work reliably in hot, demanding industrial places. Factories use them constantly. They power core processes. Metal hardening is a key use. Thyristors control the power to heat specific metal areas quickly. This hardens the surface. The metal stays tough inside. Annealing metal is another job. Here, thyristors help heat metal slowly. This makes the metal softer. It becomes easier to shape.

Forging operations need these thyristors too. Metal gets heated before hammering into shape. The thyristors ensure the metal reaches the perfect temperature. They handle the power surges smoothly. Melting metal in induction furnaces uses them. Precise power control melts metals efficiently. This saves energy.

These Russian components are known for handling high currents. They switch power accurately. This accuracy keeps production lines running. It prevents costly downtime. Their robust design handles voltage spikes. It deals with electrical noise common in factories. Long service life is important. It reduces maintenance costs.

These thyristors are workhorses. They are essential for modern metal processing. Industries rely on their performance. They make consistent, high-quality heating possible.

Company Profile

PDDN Photoelectron Technology Co., Ltd. is one of the leading enterprises in power electronics technology and power products, which is fully involved in developing solar inverters, transformers, voltage regulators, distribution cabinets, thyristors, modules, diodes, heaters, and other electronic devices or semiconductors. We will be committed to providing users with high-quality, efficient products and considerate service.

It accepts payment via Credit Card, T/T, West Union, and Paypal. PDDN will ship the goods to customers overseas through FedEx, DHL, by sea, or by air. If you want high-quality Russian phase controlled thyristor inductive thermal thyristor, please send us inquiries; we will be here to help you.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

Storage Conditions

1) Store in a dry environment at room temperature.

2) Avoid damp and high temperature.

3) Use immediately after opening the inner packing bag.

5 FAQs of Russian phase controlled thyristor inductive thermal thyristor

Russian phase controlled thyristors are solid-state power switches. They precisely manage large electrical currents in induction heating systems. These thyristors turn on and off rapidly. This controls the heat generated in metal parts.

What is this thyristor’s main job?

It controls the power going to the induction heating coil. This happens by adjusting the point in the electrical wave where the thyristor turns on. Precise timing means precise temperature control for heating metal.

Why use it for induction heating?

Induction heating needs exact power control. These thyristors handle very high currents and voltages reliably. They switch power fast. This creates the high-frequency alternating current needed for effective heating deep inside metal.

Is it reliable for tough industrial jobs?

Yes. Russian designs often emphasize ruggedness. They are built to handle the electrical stress and heat inside induction heaters. They use strong materials. Good thermal management keeps them working under heavy loads.

What makes it different from other thyristors?

Its key feature is precise phase control. This allows fine adjustment of power output. It is specifically engineered for the demanding conditions of inductive thermal applications. Think high currents, fast switching, and heat.

How do I keep it working well?

Ensure proper cooling always. Check the heatsinks and fans regularly. Keep electrical connections clean and tight. Monitor voltage and current levels. Avoid sudden power surges. Following the manufacturer’s maintenance schedule is essential.

(Russian phase controlled thyristor inductive thermal thyristor)

REQUEST A QUOTE

RELATED PRODUCTS

Integrated Circuits Chip Original Photocoupler Component Transistors Thyristor

Hydro Turbine Electric Generator 500kva Generator Ac Generator Alternator

Transistor through Hole Thyristor Product Type

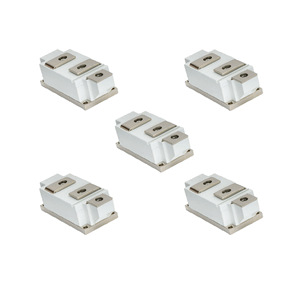

High Quality Professional SCR & TRIAC Thyristor Modules

Power Thyristor for Phase Control Triac Type