Electronic Components Supplier | Transformers, Inductors, Inverters

PRODUCT PARAMETERS

Description

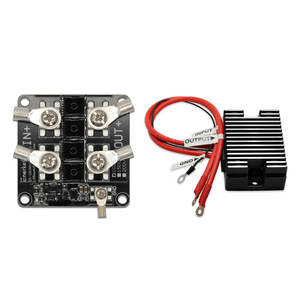

Overview of electroplating Thyristor Controlled SCR electrorefining Rectifier

Thyristor is a solid-state semiconductor device composed of four layers of alternating P- and N-type materials. It functions as a bistable switch, conducting current only when triggered by a gate signal, and remains conducting until the voltage across it drops below a certain threshold. Thyristors are widely used for controlling high-power electrical circuits, offering efficient and reliable performance in various industrial and electronic applications.

Features of electroplating Thyristor Controlled SCR electrorefining Rectifier

- High current and voltage handling capabilities

- Low on-state voltage drop, reducing power loss

- Fast switching speeds for precise control

- Latching behavior: once triggered, remains conducting without continuous gate signal

- Robust and durable design suitable for harsh environments

- Available in various types (e.g., SCR, TRIAC, GTO) for specific needs

(electroplating Thyristor Controlled SCR electrorefining Rectifier)

Specifications of electroplating Thyristor Controlled SCR electrorefining Rectifier

This electroplating rectifier supplies DC power for challenging electrorefining jobs. It utilizes thyristor-controlled SCR innovation. This style offers precise control over existing and voltage. You obtain steady power for constant plating outcomes.

The rectifier accepts conventional a/c input power. Usual voltages are 380V or 415V. Regularity is normally 50Hz or 60Hz. Result DC power is its primary job. Output voltage adjusts smoothly. Normal ranges go from 0V approximately 12V, 18V, or 24V. Outcome current is high. It can manage hundreds or hundreds of amps. Details versions provide various optimum currents. Consistent present or continuous voltage procedure is typical. You choose the best mode for your procedure.

Control is simple. A driver panel sits on the front. It reveals crucial analyses like outcome voltage and current. You established the wanted level quickly. Push-button control options exist as well. You can link it to a main system. Protection functions are built-in. It guards against overloads and short circuits. Over-temperature defense is vital. It protects against damage from overheating. The cooling system is powerful. Air or water cooling maintains points running cool. Performance is a strong point. This rectifier wastes little power. It saves running costs.

The building and construction is robust. A sturdy steel enclosure protects the interior components. It takes care of commercial settings well. Setup is created for usefulness. Connections are clearly marked. Upkeep needs are low. Integrity is high. This maker competes extended periods. It supports continual electroplating procedures. Safety and security fulfills all called for criteria.

(electroplating Thyristor Controlled SCR electrorefining Rectifier)

Applications of electroplating Thyristor Controlled SCR electrorefining Rectifier

Electroplating SCR rectifiers provide power for steel coating processes. They make use of thyristors to manage power really precisely. This exact control is vital permanently electroplating results. It makes sure a smooth, also metal layer on the component. Without this control, the plating can be uneven or weak. Operators need this accuracy for constant top quality.

These rectifiers are essential for many plating tasks. They function well for ornamental chrome plating on automobile components. They are additionally made use of for difficult chrome plating on commercial equipment elements. Zinc plating on bolts for rust defense counts on them. Gold and silver plating for jewelry and electronics utilizes them as well. The ability to fine-tune the current is key for each specific metal and finish.

Electrorefining demands secure, high-current DC power. SCR rectifiers excel right here. They purify steels like copper and nickel. The process liquifies impure steel anodes. Pure metal down payments onto cathodes. Accurate existing control is essential. It establishes the pureness and top quality of the last steel item. These rectifiers provide the consistent, high power required for large refining tanks.

Energy efficiency is a major benefit. Thyristor control minimizes wasted power. It transforms air conditioner to DC power extremely properly. This reduces electrical power expenses significantly over time. The rectifiers are constructed difficult for commercial environments. They deal with the demanding conditions of layering stores and refineries. Their integrity implies much less downtime and less production stops. Upkeep is normally simple. Basic controls make operation very easy for the customers. These features make SCR rectifiers a sensible, affordable choice for demanding steel completing and refining.

Company Profile

PDDN Photoelectron Technology Co., Ltd. is one of the leading enterprises in power electronics technology and power products, which is fully involved in developing solar inverters, transformers, voltage regulators, distribution cabinets, thyristors, modules, diodes, heaters, and other electronic devices or semiconductors. We will be committed to providing users with high-quality, efficient products and considerate service.

It accepts payment via Credit Card, T/T, West Union, and Paypal. PDDN will ship the goods to customers overseas through FedEx, DHL, by sea, or by air. If you want high-quality electroplating Thyristor Controlled SCR electrorefining Rectifier, please send us inquiries; we will be here to help you.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

Storage Conditions

1) Store in a dry environment at room temperature.

2) Avoid damp and high temperature.

3) Use immediately after opening the inner packing bag.

5 FAQs of electroplating Thyristor Controlled SCR electrorefining Rectifier

What makes SCR rectifiers better for electroplating?

Precision control matters. SCR rectifiers deliver smooth, adjustable DC power. This ensures consistent metal deposition. It reduces rejects and waste.

How do they save money?

They convert AC to DC power efficiently. Less energy gets wasted as heat. This lowers electricity bills significantly. Process control also minimizes material overuse.

Can they handle precise current needs?

Yes, absolutely. Thyristors act like fast switches. They adjust power output rapidly. This maintains exact voltage and current levels. Your plating quality stays uniform.

Are they reliable for tough factory conditions?

Built tough. SCR rectifiers handle harsh environments well. They resist dust, moisture, and heat. Good models offer easy maintenance access. Expect long service life.

What safety features exist?

Multiple protections are standard. Over-voltage, over-current, and short-circuit safeguards trigger instantly. Temperature sensors prevent overheating. These systems halt operations if danger arises. Operators stay protected.

(electroplating Thyristor Controlled SCR electrorefining Rectifier)

REQUEST A QUOTE

RELATED PRODUCTS

Permanent Magnet Generator AC Hydro Power Generators Sets 200kw

Factory LV 690V Power Factor 0.98 Thyristor Switch Control TSC 200Kvar Capacitor Automatic Compensation Device

Voltage Stabilizer Regulator

thyristor power controller scr power thyristor discrete thyristor

High Quality Thyristor