Electronic Components Supplier | Transformers, Inductors, Inverters

PRODUCT PARAMETERS

Description

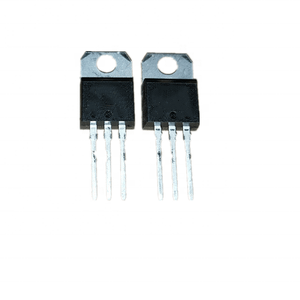

Overview of Thyristor Module welding motor control soft start module

Thyristor is a solid-state semiconductor device composed of four layers of alternating P- and N-type materials. It functions as a bistable switch, conducting current only when triggered by a gate signal, and remains conducting until the voltage across it drops below a certain threshold. Thyristors are widely used for controlling high-power electrical circuits, offering efficient and reliable performance in various industrial and electronic applications.

Features of Thyristor Module welding motor control soft start module

- High current and voltage handling capabilities

- Low on-state voltage drop, reducing power loss

- Fast switching speeds for precise control

- Latching behavior: once triggered, remains conducting without continuous gate signal

- Robust and durable design suitable for harsh environments

- Available in various types (e.g., SCR, TRIAC, GTO) for specific needs

(Thyristor Module welding motor control soft start module)

Specifications of Thyristor Module welding motor control soft start module

This thyristor module handles motor control and soft start jobs. It works well for welding gear too. The module uses solid-state thyristor switches. These switches manage heavy electrical power smoothly. They control motor speed precisely. They also start big motors gently. This soft start feature is key. It stops sudden power surges. Motors last longer. Electrical systems face less stress.

The module adjusts power flow using phase angle control. This means it finely tunes voltage and current. It delivers exactly what the motor needs. This happens instantly. You get smooth operation. Energy waste drops significantly. Heat generation stays low. Efficiency improves overall. The unit fits standard power systems. It connects directly to motors. Setup is straightforward.

Built tough for industrial places. It uses strong metal cases. Heat sinks keep things cool. Fans or water cooling options exist. This handles high heat loads. Electrical connections use screw terminals. These are reliable. They handle thick cables. Mounting is simple. Fix it onto a panel or rack. The design focuses on easy service. Parts can be swapped if needed.

Control happens through simple signals. Use analog voltage or current inputs. Digital signals work too. Receive feedback for monitoring. See motor speed or power use. Protect against overloads. Built-in safety trips cut power fast. This prevents damage. Options include communication ports. Link to PLCs or control networks. Remote operation becomes possible.

This module replaces older contactor starters. Those cause mechanical wear. They create power spikes. Thyristor control is silent. It has no moving parts. Motors start and run smoother. Equipment faces less vibration. Maintenance demands fall. Production uptime increases. Costs go down over time. The solid-state design is dependable. It offers long service life. Expect consistent performance year after year.

(Thyristor Module welding motor control soft start module)

Applications of Thyristor Module welding motor control soft start module

Thyristor modules are tough power switches. They handle big jobs in industry. Welding machines use them heavily. These modules control the welding current precisely. They adjust it fast for different materials. This makes welding strong and consistent. It prevents weak spots in the weld. Things like metal thickness change the needed power. Thyristor modules react instantly. This keeps the weld quality high every time.

Motor control is another big area. Big motors need careful starting. They also need smooth speed changes. Thyristor modules manage this well. They start motors gradually. This avoids huge power surges. Power surges stress electrical systems. They can even cause blackouts. Thyristor modules prevent that. They also let operators adjust motor speed finely. This is vital for many machines. Conveyors, pumps, and fans all need this control. It saves energy too. Motors only use the power they actually need.

Soft starting is a key feature. Starting big motors directly is rough. It jerks the machine. It pulls too much electricity suddenly. Thyristor modules provide a soft start. They ramp up the motor speed slowly. This protects the motor windings. It reduces wear on belts and gears. The whole machine lasts longer. The electrical supply stays stable. Other equipment on the same line isn’t affected. This avoids annoying voltage dips. Factories rely on this smooth operation. It keeps production lines running without hiccups.

These modules are built tough. They handle high voltage and high current. Industrial environments are harsh. Heat, dust, and vibration are common. Thyristor modules withstand these conditions. They need little maintenance. This cuts downtime. They are a reliable solution for demanding power control tasks.

Company Profile

PDDN Photoelectron Technology Co., Ltd. is one of the leading enterprises in power electronics technology and power products, which is fully involved in developing solar inverters, transformers, voltage regulators, distribution cabinets, thyristors, modules, diodes, heaters, and other electronic devices or semiconductors. We will be committed to providing users with high-quality, efficient products and considerate service.

It accepts payment via Credit Card, T/T, West Union, and Paypal. PDDN will ship the goods to customers overseas through FedEx, DHL, by sea, or by air. If you want high-quality Thyristor Module welding motor control soft start module, please send us inquiries; we will be here to help you.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

Storage Conditions

1) Store in a dry environment at room temperature.

2) Avoid damp and high temperature.

3) Use immediately after opening the inner packing bag.

5 FAQs of Thyristor Module welding motor control soft start module

Thyristor modules control welding motor starts. Many people ask questions about these soft start modules. Here are five common ones.

What does this thyristor module actually do? It manages the power going to your welding motor. It makes the motor start slowly. This prevents sudden jolts. It protects your motor and welding equipment. You avoid damage from high starting currents.

Why pick a thyristor soft starter over other methods? It offers smooth acceleration. This is vital for stable welding arcs. It reduces stress on the motor windings. Your motor lasts longer. It also cuts down electrical surges. This protects your whole power system.

How difficult is the setup for this module? Installation is straightforward. You connect it between your power source and the motor. Follow the wiring diagram carefully. Basic settings need adjustment. You set the start time and initial torque. A technician can do this quickly.

What problems might I face using this module? Sometimes the motor doesn’t start smoothly. Check the control signal connections. Ensure the thyristors receive the right trigger pulses. Look for loose wires. Overheating is another possible issue. Verify the cooling system works. Make sure the load isn’t too heavy for the module rating.

Are there important safety steps? Always disconnect power before working on the module. Never touch live terminals. Use proper lockout/tagout procedures. Ensure the module is correctly grounded. Check all connections are tight. Regularly inspect for dust or damage. Good ventilation is essential.

(Thyristor Module welding motor control soft start module)

REQUEST A QUOTE

RELATED PRODUCTS

High Quality D32cm 240VAC DOB Thyristor Dimmable 28W Ring 2835SMD 150LM/W 90Ra 3000 4000k Printed Circuit Board LED PCB Modules

Whole KP Series SCR Thyristor 300A 500A 1600V Phase Control Thyristor

200A 300V Thyristor Rectifier Use for Electrophoresis

3 Phase Thyristor Regulator 220v 480VAC SCR Power Regulator Voltage Controller

IGBT MODULE IGBT POWER MODULE DIODE Thyristor SCR Electronics component transistors mosfet