Electronic Components Supplier | Transformers, Inductors, Inverters

PRODUCT PARAMETERS

Description

Overview of High power thyristor for phase control applications

Thyristor is a solid-state semiconductor device composed of four layers of alternating P- and N-type materials. It functions as a bistable switch, conducting current only when triggered by a gate signal, and remains conducting until the voltage across it drops below a certain threshold. Thyristors are widely used for controlling high-power electrical circuits, offering efficient and reliable performance in various industrial and electronic applications.

Features of High power thyristor for phase control applications

- High current and voltage handling capabilities

- Low on-state voltage drop, reducing power loss

- Fast switching speeds for precise control

- Latching behavior: once triggered, remains conducting without continuous gate signal

- Robust and durable design suitable for harsh environments

- Available in various types (e.g., SCR, TRIAC, GTO) for specific needs

(High power thyristor for phase control applications)

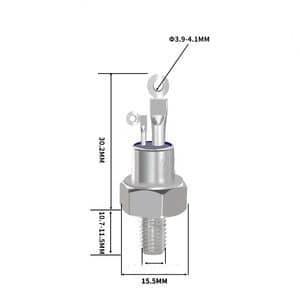

Specifications of High power thyristor for phase control applications

High power thyristors constructed for stage control jobs take care of difficult problems. These gadgets switch over large air conditioner currents reliably. They handle power circulation in heating systems, electric motor drives, and commercial lights systems. Obstructing voltage is key. Try to find rankings like 1200V, 1600V, or even 2500V. This voltage score suggests the thyristor quits current circulation correctly when reverse-biased. It stops break down under high voltage anxiety.

Existing handling matters substantially. High power thyristors carry average currents from 100 amps up to several thousand amps. Peak surge existing ability is crucial as well. It shields against unexpected overloads. These gadgets make it through huge, brief current spikes without damage. Proper thermal design is non-negotiable. Big semiconductor dies and strong bundles manage warm. The thermal resistance value is important. A reduced number suggests much better heat transfer far from the silicon. Efficient heatsinking is necessary. Good installing makes certain the joint temperature stays secure.

Gate triggering requires careful layout. Regular turn-on is vital for accurate phase control. Eviction current and voltage levels have to be right. This makes certain dependable changing every single time. The thyristor responds quickly to the gate pulse. Rugged building is typical. These thyristors use robust real estates like press-pack or stud-mount types. They endure mechanical anxiety and thermal cycling. This toughness is vital for many years of service in demanding manufacturing facilities. Designers rely on these parts for steady, effective power policy. They finish the job under heavy electrical tons.

(High power thyristor for phase control applications)

Applications of High power thyristor for phase control applications

High power thyristors manage serious electrical lots. They master stage control applications. Stage control takes care of air conditioner power circulation. It readjusts the factor within each AC half-cycle where the thyristor switches on. This controls the ordinary power provided to a tons. High power thyristors are built for this switching job. They manage huge currents and high voltages reliably.

These components function utilizing a gate signal. A small pulse put on eviction terminal triggers the thyristor to perform. It stays carrying out up until the current declines nearly to zero. This happens naturally at the end of each air conditioner half-cycle. Regulating the timing of the gate pulse regulates the power output. The later the pulse shows up, the less power streams to the load. This is phase control.

High power thyristors for stage control have particular strengths. They obstruct high reverse voltages. They hold up against huge surge currents. They handle high rates of existing surge (dI/dt). They deal with considerable thermal tension. These attributes are vital for industrial settings. They make sure steady operation under difficult problems. Sturdy construction avoids failings. This reliability is critical.

These thyristors find use in lots of locations. Industrial heating systems rely upon them. They control power to heaters and ovens exactly. Electric motor rate controllers use them for smooth operation. Lighting systems, specifically big ones, use them for dimming. Battery chargers use them for reliable power guideline. Power supplies convert air conditioner to DC utilizing them. They handle big power streams in these applications effectively. They offer economical control for hefty electrical lots.

Company Profile

PDDN Photoelectron Technology Co., Ltd. is one of the leading enterprises in power electronics technology and power products, which is fully involved in developing solar inverters, transformers, voltage regulators, distribution cabinets, thyristors, modules, diodes, heaters, and other electronic devices or semiconductors. We will be committed to providing users with high-quality, efficient products and considerate service.

It accepts payment via Credit Card, T/T, West Union, and Paypal. PDDN will ship the goods to customers overseas through FedEx, DHL, by sea, or by air. If you want high-quality High power thyristor for phase control applications, please send us inquiries; we will be here to help you.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

Storage Conditions

1) Store in a dry environment at room temperature.

2) Avoid damp and high temperature.

3) Use immediately after opening the inner packing bag.

5 FAQs of High power thyristor for phase control applications

What makes a thyristor suitable for high-power phase control?

High-power thyristors handle very large currents and voltages. They need thick silicon wafers and big packages. This lets them manage the heat generated during phase control switching. They also switch reliably at mains frequencies like 50Hz or 60Hz. Their design prevents failure under heavy electrical stress.

How do you trigger these high-power thyristors?

A gate pulse starts the thyristor conducting. Precise timing of this pulse controls the phase angle. This decides how much power gets delivered to the load. High-power gates need strong, clean pulses. Isolated gate drivers are usually necessary for safety. They protect the control circuit from the main high voltage.

Why is heat management so critical?

Phase control causes significant heat inside the thyristor. Large currents flow only part of the time. This creates high power losses. Proper heatsinks are absolutely essential. They pull heat away from the thyristor body. Good thermal paste improves contact. Air or liquid cooling might be needed for the biggest units. Overheating destroys the device fast.

What protection do these thyristors need?

High-power circuits are tough. Sudden voltage spikes can break the thyristor. Snubber circuits absorb these spikes. Fast fuses guard against huge short-circuit currents. Overvoltage protection devices like MOVs help too. Monitoring temperature prevents thermal runaway. Good protection ensures long life.

How reliable are high-power phase control thyristors?

They are built tough for industrial use. Properly selected and installed thyristors last years. They withstand electrical noise common in factories. Following voltage and current ratings is key. Good cooling and protection boost reliability significantly. They are a proven solution for demanding motor drives and heating controls.

(High power thyristor for phase control applications)

REQUEST A QUOTE

RELATED PRODUCTS

scr thyristor module semiconductor module phase control Thyristors

New and Original Transistor diode types of thyristor diode smd triacs transistor

Disc Type Fast Switching Thyristor / fast SCR / fast Thyristor

200A 300V Thyristor Rectifier Use for Electrophoresis

Foot Pedal Spot Welding Machine Thyristor Controller Resistor Welder Electrode Arm High Quality