Electronic Components Supplier | Transformers, Inductors, Inverters

PRODUCT PARAMETERS

Description

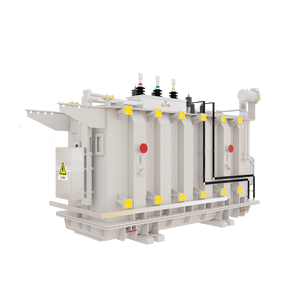

Overview of 2000kVA Oil Immersed Transformer Three Phase Distribution Transformer 220V/380V/440V Output 60Hz 10kV 35kV 6kV 220kV 132kV

An oil-immersed transformer is a type of electrical transformer where the core and windings are submerged in an insulating oil. This oil serves two primary functions: it acts as a highly effective insulator between conductive parts and as a coolant to dissipate heat generated during operation. These transformers are robust, reliable, and highly efficient, making them the standard choice for high-voltage power distribution and transmission networks, typically installed outdoors in substations.

Features of 2000kVA Oil Immersed Transformer Three Phase Distribution Transformer 220V/380V/440V Output 60Hz 10kV 35kV 6kV 220kV 132kV

- Effective Cooling: The insulating oil efficiently absorbs heat from the core and windings and transfers it to the radiator fins, allowing for natural or forced circulation and higher overload capacity.

- Superior Insulation: The oil provides much better dielectric strength than air, allowing for a more compact design for a given voltage rating and protecting against short circuits.

- Robust Construction: Designed for long-term, reliable operation (often 25-30 years) in harsh outdoor environments.

- Overload Capacity: Can handle temporary power overloads better than dry-type transformers due to the thermal mass and cooling properties of the oil.

- Protection System: Equipped with a conservator tank (to allow for oil expansion), breather (to absorb moisture from air), and protective relays (Buchholz relay) for internal fault detection.

- Cost-Effective: Generally more economical for high-power applications compared to dry-type transformers.

Specifications of 2000kVA Oil Immersed Transformer Three Phase Distribution Transformer 220V/380V/440V Output 60Hz 10kV 35kV 6kV 220kV 132kV

This 2000kVA transformer is built for heavy-duty power distribution. It uses oil immersion cooling for reliable operation. The transformer handles three-phase electrical systems. Its primary job is stepping down high transmission voltages to usable levels. Key input voltages include 10kV, 35kV, 6kV, 132kV, and even 220kV. The output provides standard lower voltages: 220V, 380V, and 440V. It operates at 60Hz frequency.

The core and windings sit inside a strong, welded steel tank filled with special insulating oil. This oil cools the transformer and prevents electrical breakdown. Radiators attached to the tank help dissipate heat effectively. This design ensures stable performance under full 2000kVA load. Expect low losses and high efficiency.

This transformer is very adaptable. It connects easily to various high-voltage power grids. The standard outputs suit industrial machinery, commercial buildings, and large facilities. Its robust construction withstands demanding environments. Routine maintenance is straightforward. Oil levels and temperature gauges are easy to monitor. Access points allow for sampling and testing the oil.

Safety features are integral. The tank is fully sealed to prevent oil leaks. Pressure relief devices protect against internal faults. Grounding points ensure safe installation. It meets strict industry standards for electrical safety and performance. This transformer delivers dependable power for critical operations. It offers long service life with proper care. Consider it for reliable voltage conversion where substantial power is needed.

Applications of 2000kVA Oil Immersed Transformer Three Phase Distribution Transformer 220V/380V/440V Output 60Hz 10kV 35kV 6kV 220kV 132kV

This 2000kVA oil immersed transformer is a three-phase distribution unit. It handles heavy-duty power distribution tasks. You find it commonly stepping down high transmission voltages to usable levels for industry and large facilities. Its oil cooling is key. This design efficiently dissipates heat generated during operation. This allows continuous, reliable service under significant electrical loads.

Think factories, manufacturing plants, and processing facilities. These places need lots of power. This transformer takes high incoming voltages like 10kV, 35kV, or even 132kV or 220kV. It converts this power down to lower, safer outputs. Common outputs are 220V, 380V, or 440V at 60Hz frequency. This directly powers heavy machinery, motors, lighting systems, and entire plant operations.

It’s also vital in electrical substations. Here, it acts as an intermediate step. It receives very high voltage from the main grid. It then reduces this voltage for further distribution through local networks. This makes the power safer and easier to manage over shorter distances.

Large commercial complexes benefit too. Think shopping malls, hospitals, or university campuses. These buildings have massive power demands. This transformer ensures stable, consistent voltage levels throughout the complex. It prevents damaging voltage drops or surges.

Renewable energy sites use this transformer type. Wind farms or solar installations generate power. This transformer steps up their output voltage for efficient long-distance transmission to the grid. It also steps down incoming grid power for site operations.

The oil immersion provides superior insulation and cooling. This makes the transformer robust. It withstands harsh environments, temperature fluctuations, and electrical stresses. This reliability minimizes downtime. Maintenance is generally simpler compared to some dry-type units. The large 2000kVA capacity means it powers substantial operations. It connects reliably to standard North American 60Hz grids. Its design prioritizes longevity and consistent performance day after day.

Company Profile

PDDN Photoelectron Technology Co., Ltd. is one of the leading enterprises in power electronics technology and power products, which is fully involved in developing solar inverters, transformers, voltage regulators, distribution cabinets, thyristors, modules, diodes, heaters, and other electronic devices or semiconductors. We will be committed to providing users with high-quality, efficient products and considerate service.

It accepts payment via Credit Card, T/T, West Union, and Paypal. PDDN will ship the goods to customers overseas through FedEx, DHL, by sea, or by air. If you want high-quality 2000kVA Oil Immersed Transformer Three Phase Distribution Transformer 220V/380V/440V Output 60Hz 10kV 35kV 6kV 220kV 132kV, please send us inquiries; we will be here to help you.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

Storage Conditions

1) Store in a dry environment at room temperature.

2) Avoid damp and high temperature.

3) Use immediately after opening the inner packing bag.

5 FAQs of 2000kVA Oil Immersed Transformer Three Phase Distribution Transformer 220V/380V/440V Output 60Hz 10kV 35kV 6kV 220kV 132kV

Here are five common questions about the 2000kVA Oil Immersed Three Phase Distribution Transformer:

What is this transformer for? It moves large amounts of electrical power. It steps down high voltages for factories, buildings, or substations. It handles 2000kVA loads reliably. It connects to different high voltage systems. It delivers lower voltage power safely.

What voltages can it work with? Inputs include 10kV, 35kV, 6kV, 220kV, 132kV. Outputs are standard lower voltages: 220V, 380V, 440V. You specify the exact input and output needed when ordering. It works with three-phase electrical systems at 60Hz.

How big and heavy is it? It is a substantial piece of equipment. Expect a weight around 5000 kg or more. Exact size and weight depend on the specific voltage ratings chosen. You need space and proper lifting gear for installation. Check the detailed datasheet for your model.

Why does it use oil? The oil cools the transformer. It absorbs heat generated during operation. The oil also provides vital electrical insulation inside the tank. This design allows efficient cooling for continuous heavy loads. Regular oil checks and maintenance are essential.

How long will it last? These transformers are built tough. With proper installation and regular maintenance, expect 25 to 30 years of service. Maintenance includes checking oil quality and electrical connections. Protecting it from overloads and environmental damage extends its life significantly.

REQUEST A QUOTE

RELATED PRODUCTS

JLSW3-10 Outdoor Oil-Immersed Combined Transformer, metering tank

Electrostatic precipitator rectifier silicon transformer China Manufacturer

10/11kV Industrial Oil Immersed Transformer for Electrical Substation

Factory Three-phase Oil-immersed Power Transformer 35kV Suitable for Industrial and Mining Use, Sturdy and Durable

High Quality 11kv 22kv 33kv 35kv 5mva 5000kva Oil Immersed Power Transformer Low Step Down Three Phase