Electronic Components Supplier | Transformers, Inductors, Inverters

PRODUCT PARAMETERS

Description

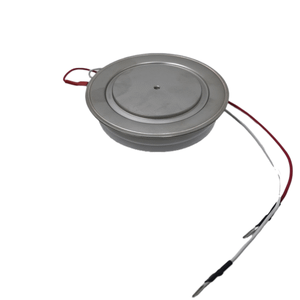

Overview of Thyristor for Power Rectifier Power Supply of Induction Furnace

Thyristor is a solid-state semiconductor device composed of four layers of alternating P- and N-type materials. It functions as a bistable switch, conducting current only when triggered by a gate signal, and remains conducting until the voltage across it drops below a certain threshold. Thyristors are widely used for controlling high-power electrical circuits, offering efficient and reliable performance in various industrial and electronic applications.

Features of Thyristor for Power Rectifier Power Supply of Induction Furnace

- High current and voltage handling capabilities

- Low on-state voltage drop, reducing power loss

- Fast switching speeds for precise control

- Latching behavior: once triggered, remains conducting without continuous gate signal

- Robust and durable design suitable for harsh environments

- Available in various types (e.g., SCR, TRIAC, GTO) for specific needs

(Thyristor for Power Rectifier Power Supply of Induction Furnace)

Specifications of Thyristor for Power Rectifier Power Supply of Induction Furnace

These thyristors are developed hard for induction heating system power products. They take care of the high currents required for melting steel. You need components that work reliably under heavy lots for long periods.

Voltage scores are critical here. Our thyristors deal with high obstructing voltages, normally 1200V to 2500V or even more. This safety margin protects versus unforeseen voltage spikes common in heater operations. Existing scores are just as important. Devices are readily available for continuous currents from hundreds to several thousand amps. Peak surge present capacity is likewise high. This deals with the extreme starting currents heating systems need.

Thermal performance is non-negotiable. The thyristor joint need to remain trendy. Our designs include reduced thermal resistance from joint to situation. They successfully move warmth right into the heatsink. Correct cooling is essential. Optimum joint temperature level ratings are purely applied. Overheating destroys the gadget quickly.

Causing needs precision. Entrance drive needs are plainly specified. This ensures quickly, reputable turn-on every single time. Crucial switching parameters like turn-on time and turn-off time are specified. Fast, regular changing minimizes power loss. It keeps the rectifier reliable.

Protection is built-in. High dv/dt ratings prevent undesirable turn-on from rapid voltage adjustments. High di/dt scores allow the thyristor to handle fast current rises safely. These functions are critical for stable heating system operation. They protect against problem failures.

(Thyristor for Power Rectifier Power Supply of Induction Furnace)

Applications of Thyristor for Power Rectifier Power Supply of Induction Furnace

Thyristors handle critical jobs inside induction furnace power rectifier power supplies. These power units change AC electricity into strong DC electricity. The furnace needs this DC power to melt metal efficiently. Thyristors act like super-fast, heavy-duty switches. They control the huge power flow precisely. This precise control is vital for stable furnace operation.

Old systems used mechanical switches or basic diodes. They wasted more energy. They struggled with quick adjustments. Thyristors fix these problems. They allow smooth, instant changes to the output power. Operators adjust the metal melting speed easily. They keep the exact temperature needed for different metals. This control improves melting quality and saves significant energy.

Thyristors handle the tough environment near big furnaces. They manage high voltage and massive current surges reliably. Their solid-state design means no moving parts to break. This leads to much less downtime for repairs. Maintenance costs drop sharply. Furnaces run longer without stopping.

The thyristor rectifier system adjusts power fast. It responds immediately when the metal load changes inside the furnace. This quick response protects the furnace lining. It prevents damage from power spikes. Consistent power flow means smoother melting and better metal quality. Production becomes more predictable.

Thyristors make the entire power conversion process more efficient. Less electricity turns into wasted heat. More power goes directly into melting the metal. This cuts operating costs substantially. Furnace owners see lower electricity bills. Thyristor systems also offer flexibility. They work well with different furnace sizes and power sources. Upgrading an old furnace power supply with thyristors brings these benefits fast. The result is a stronger, smarter, more cost-effective melting operation.

Company Profile

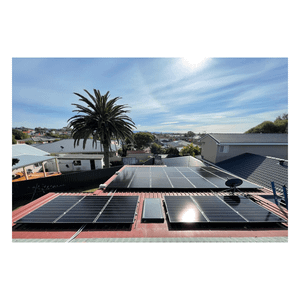

PDDN Photoelectron Technology Co., Ltd. is one of the leading enterprises in power electronics technology and power products, which is fully involved in developing solar inverters, transformers, voltage regulators, distribution cabinets, thyristors, modules, diodes, heaters, and other electronic devices or semiconductors. We will be committed to providing users with high-quality, efficient products and considerate service.

It accepts payment via Credit Card, T/T, West Union, and Paypal. PDDN will ship the goods to customers overseas through FedEx, DHL, by sea, or by air. If you want high-quality Thyristor for Power Rectifier Power Supply of Induction Furnace, please send us inquiries; we will be here to help you.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

Storage Conditions

1) Store in a dry environment at room temperature.

2) Avoid damp and high temperature.

3) Use immediately after opening the inner packing bag.

5 FAQs of Thyristor for Power Rectifier Power Supply of Induction Furnace

Thyristors control the electrical power going into your induction furnace. They act like fast switches. They turn the alternating current (AC) from the mains into direct current (DC). The furnace needs DC power to melt metal efficiently. Good thyristors mean stable melting and lower energy costs.

What exactly do thyristors do in this power supply?

Thyristors act as the main control switch. They precisely manage the huge electrical current needed by the furnace coil. They switch the power on and off very quickly. This controls the heat level inside the furnace crucible.

Why use thyristors instead of other parts?

Thyristors handle extremely high power levels. They manage thousands of amps reliably. They switch very fast for precise temperature control. This is vital for consistent metal melting. Other parts often cannot handle this much power or switch this fast.

Do thyristors need special cooling?

Yes, absolutely. They get very hot during operation. Overheating damages them fast. They require strong cooling systems. Usually, water flows through special coolers attached directly to the thyristors. Good cooling is critical for long life.

How long do these thyristors typically last?

Their lifespan depends heavily on operating conditions. Proper cooling and stable power are key. With good conditions and no surges, expect several years of service. Check them regularly during maintenance. Replace them if they show signs of damage or wear.

What happens if a thyristor fails?

A failed thyristor usually causes a power loss. The furnace might stop heating completely. It might heat unevenly. This stops production immediately. You need to replace the faulty part quickly. Always keep spare thyristors available to reduce downtime.

(Thyristor for Power Rectifier Power Supply of Induction Furnace)

REQUEST A QUOTE

RELATED PRODUCTS

electroplating Thyristor Controlled SCR electrorefining Rectifier

High-Power DC Three-phase Rectifier Bridge Rectifier Module MDS60A100A200A500A12V/220V

Induction Heating Furnace

Power Transistor Triode

two-way triac stud thyristor