Electronic Components Supplier | Transformers, Inductors, Inverters

PRODUCT PARAMETERS

Description

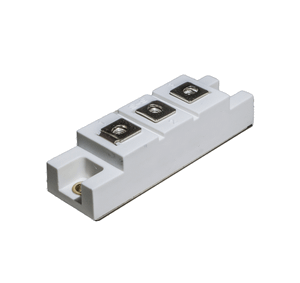

Overview of Thyristor for Power Rectifier Power Supply of Induction Furnace

Thyristor is a solid-state semiconductor device composed of four layers of alternating P- and N-type materials. It functions as a bistable switch, conducting current only when triggered by a gate signal, and remains conducting until the voltage across it drops below a certain threshold. Thyristors are widely used for controlling high-power electrical circuits, offering efficient and reliable performance in various industrial and electronic applications.

Features of Thyristor for Power Rectifier Power Supply of Induction Furnace

- High current and voltage handling capabilities

- Low on-state voltage drop, reducing power loss

- Fast switching speeds for precise control

- Latching behavior: once triggered, remains conducting without continuous gate signal

- Robust and durable design suitable for harsh environments

- Available in various types (e.g., SCR, TRIAC, GTO) for specific needs

(Thyristor for Power Rectifier Power Supply of Induction Furnace)

Specifications of Thyristor for Power Rectifier Power Supply of Induction Furnace

Thyristors form the heart of the power rectifier supplying your induction furnace. They manage the massive electrical currents needed for efficient melting. Choosing the correct thyristor specifications is critical for reliable furnace operation and long service life.

Voltage rating is essential. Thyristors must handle the rectifier’s peak reverse voltage safely. Standard voltage blocking levels range from 1200V to 3600V or higher. The specific furnace voltage determines the required thyristor rating. Adequate margin prevents voltage breakdown during line surges.

Current handling defines power capacity. Average current ratings typically span 500A to 3000A per thyristor module. Modules often combine multiple thyristors. The furnace’s maximum operating current dictates the thyristor size. High surge current capability is vital. This handles the initial furnace start-up load safely. It protects against unexpected short circuits.

Thermal management is non-negotiable. Thyristors generate significant heat under load. Efficient cooling maintains safe junction temperatures. Water cooling is the standard method for high-power induction furnaces. Air cooling might work for smaller units. Proper heat sink design and clean coolant flow prevent overheating failures.

Triggering precision ensures stable output. The gate drive circuit must fire the thyristors accurately every cycle. Consistent timing guarantees smooth DC output from the rectifier. This stable DC power is crucial for consistent furnace melting performance. Good gate drive design minimizes timing drift.

Reliability features protect your investment. Built-in snubber circuits manage voltage spikes during switching. Fast-acting fuses provide short-circuit protection. Monitoring points allow checking thyristor health during operation. Rugged mechanical construction withstands industrial vibration. These features maximize uptime and reduce maintenance costs.

(Thyristor for Power Rectifier Power Supply of Induction Furnace)

Applications of Thyristor for Power Rectifier Power Supply of Induction Furnace

Thyristors handle the power conversion in induction furnace rectifier supplies. They control the large AC current from the grid. We turn this into the DC current the furnace needs. Precise control matters here. Thyristors do this job well.

Older systems used diodes or tap changers. They were less flexible. Thyristors give us much finer adjustment. We control the output voltage and current very accurately. This happens by managing the point we trigger the thyristor on during each AC cycle. Think of it like a fast, precise switch. We decide exactly when it conducts power each cycle.

This precise control is vital for furnace operation. It lets operators set the perfect power level for melting. They match the power to the material in the crucible. They also match the power to the melting stage. Fine control improves melting efficiency. Less energy gets wasted as heat elsewhere. This saves money. It also makes the process more consistent.

Thyristor rectifiers react fast. Power demand changes quickly in a furnace. The load shifts as metal melts. Thyristor systems adjust power output almost instantly. They keep the melting process stable. This avoids problems like power surges. It protects the furnace lining. Consistent power gives better metal quality too.

These systems handle big power surges well. Starting a cold furnace needs a big power hit. Thyristors manage this initial inrush smoothly. They prevent damaging spikes on the power line. This protects the furnace components. It also protects the wider electrical supply network. Reliability is key. Thyristor systems are robust. They work well in the tough conditions near a furnace. Heat, vibration, and electrical noise are common. Good design handles these factors.

Company Profile

PDDN Photoelectron Technology Co., Ltd. is one of the leading enterprises in power electronics technology and power products, which is fully involved in developing solar inverters, transformers, voltage regulators, distribution cabinets, thyristors, modules, diodes, heaters, and other electronic devices or semiconductors. We will be committed to providing users with high-quality, efficient products and considerate service.

It accepts payment via Credit Card, T/T, West Union, and Paypal. PDDN will ship the goods to customers overseas through FedEx, DHL, by sea, or by air. If you want high-quality Thyristor for Power Rectifier Power Supply of Induction Furnace, please send us inquiries; we will be here to help you.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

Storage Conditions

1) Store in a dry environment at room temperature.

2) Avoid damp and high temperature.

3) Use immediately after opening the inner packing bag.

5 FAQs of Thyristor for Power Rectifier Power Supply of Induction Furnace

Thyristors control the electrical power going into your induction furnace. They work like high-speed switches for the main current. This FAQ answers common questions about their role in power rectifier supplies.

What exactly do thyristors do in this power supply? They manage the AC power coming in. They convert it into the DC power the furnace needs. They also precisely adjust the power level delivered. This control is vital for stable furnace operation.

Why use thyristors instead of simple diodes? Diodes only let current flow one way. Thyristors do that too. But thyristors also let you control exactly when they turn on during the AC cycle. This timing control is how we adjust the power output smoothly. Diodes cannot do this.

What usually makes a thyristor fail in this tough job? Overheating is the biggest enemy. Electrical surges or spikes can kill them instantly. Overcurrent events push them beyond their limits. Poor cooling or bad connections often cause overheating. Voltage spikes from the furnace or grid are also risky.

Do thyristors need regular maintenance checks? Yes, absolutely. Visually inspect them for physical damage or burn marks. Check all electrical connections are tight and clean. Monitor cooling systems are working perfectly. Use diagnostic tools to check their triggering signals are correct. Watch for unusual temperature rises.

How do I know if my thyristor rectifier is performing well? Look at the DC output voltage and current waveforms. They should be clean and stable under load. The power control should respond quickly and accurately. The system should reach its full rated power output. Consistent, trouble-free operation over time is the best sign.

(Thyristor for Power Rectifier Power Supply of Induction Furnace)

REQUEST A QUOTE

RELATED PRODUCTS

High-power electronic voltage regulator 5000W 220V with Shell thyristor voltage regulator temperature dimming

Original New SCR Module for Welding Machine In stock

Integrated Circuits Chip Original Photocoupler Component Transistors Thyristor

Original Photocoupler Integrated Circuits Chip Component Transistors Thyristor

High Quality Thyristor