Electronic Components Supplier | Transformers, Inductors, Inverters

PRODUCT PARAMETERS

Description

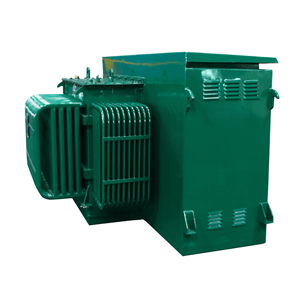

Overview of 200kva 20kV ANSI/IEEE Standards Loop Feed Radial Feed Supply Pad Mounted Transformer

200kva 20kV ANSI/IEEE Standards Loop Feed Radial Feed Supply Pad Mounted Transformer is an enclosed, ground-level electrical distribution transformer commonly used in underground (UG) power systems. It steps down primary high-voltage electricity (e.g., 15kV or 25kV) to a lower secondary voltage (e.g., 120/240V or 480V) for safe distribution to residential neighborhoods, commercial buildings, and industrial parks. Its robust, lockable steel enclosure makes it safe for public areas.

Features of 200kva 20kV ANSI/IEEE Standards Loop Feed Radial Feed Supply Pad Mounted Transformer

Ground-Level Enclosure: A locked, tamper-resistant, weatherproof steel cabinet that protects the internal components and ensures public safety.

Underground Cable Connections: Designed for easy connection to underground primary (high-voltage) and secondary (low-voltage) cables via compartments with built-in bushings.

Compartmentalization: Separate, isolated compartments for high-voltage and low-voltage components, enhancing safety during maintenance.

Ventilation: Designed with louvers or other ventilation systems to allow for proper heat dissipation from the transformer core and coils.

Lifting Lugs: Integrated lifting lugs for easy and safe installation and replacement using a crane or hoist.

Tamper-proof Hardware: Lockable doors with special bolts to prevent unauthorized access.

Fused Switches: Often includes fused disconnect switches for circuit protection and safe isolation.

Pad Foundation: Installed on a concrete pad (“pad-mounted”) to provide a stable, level base.

Specifications of 200kva 20kV ANSI/IEEE Standards Loop Feed Radial Feed Supply Pad Mounted Transformer

This 200kVA pad-mounted transformer connects directly to 20kV utility distribution systems. It’s built tough for outdoor use. The design follows strict ANSI/IEEE standards. This ensures reliability and safety. The transformer handles radial feed applications. Power flows in one direction to the load. It also supports loop feed setups. Power can enter one side and exit the other. This provides flexibility for network configurations. It’s built for mounting on a concrete pad at ground level.

The primary voltage is 20,000 volts. The secondary voltage is typically 480Y/277V or 208Y/120V. Standard bushings are on the sides. These accept separable insulated high-voltage connectors. The enclosure is heavy-duty steel. It resists corrosion and tampering. Padlock provisions are standard. This keeps unauthorized people out. Internal components are well-protected. The core and coils use high-grade materials. This minimizes energy losses. Efficiency is a priority.

Cooling is natural convection (OA). No fans or pumps are needed. This makes it quiet and low-maintenance. The transformer manages temperature rise effectively. This extends its operational life. It includes pressure relief devices. These protect against internal faults. Fault current withstand ratings meet ANSI requirements. The transformer handles short circuits safely. Fluid options include standard mineral oil. Less-flammable fluids are available too. This depends on installation rules. Accessories like gauges and surge arresters are optional. They enhance monitoring and protection.

Installation and service are straightforward. The design prioritizes technician safety. Clearances inside the enclosure are adequate. Routine checks are easy. This transformer delivers dependable power. It’s suited for commercial buildings or small industrial sites. Its robust construction ensures long-term performance. Compliance with ANSI/IEEE standards is guaranteed.

Applications of 200kva 20kV ANSI/IEEE Standards Loop Feed Radial Feed Supply Pad Mounted Transformer

This 200kVA, 20kV pad-mounted transformer meets strict ANSI/IEEE standards. It’s built for underground power distribution. Utilities use it widely. It works reliably in loop feed and radial feed setups.

Loop feed systems need dependable transformers. This unit handles that job. It allows power to flow in a continuous ring. If one section fails, power reroutes around the fault. This design minimizes outages for customers. It keeps the lights on for more people. The transformer connects seamlessly into these critical loops.

Radial feed systems are simpler. Power flows from a single source out to customers. This transformer serves well in these lines too. It steps down the 20kV distribution voltage to usable levels for homes or businesses. It delivers stable power where needed. Its compact pad-mounted design saves space.

The transformer sits inside a tough steel box. This box is locked and tamper-proof. It protects people from high voltage inside. The enclosure resists corrosion and weather. It stands up to harsh outdoor conditions year after year. The unit installs on a concrete pad above ground. This makes access easy for maintenance crews.

Safety is a major focus. The design includes pressure relief devices. These prevent dangerous buildup if internal problems occur. The transformer uses mineral oil for cooling and insulation. The tank contains this oil securely. Leakage is minimized. This protects the environment and prevents fire hazards.

Maintenance is straightforward. Crews can check oil levels and connections quickly. Terminations for underground cables are accessible. They are designed for reliability. The transformer offers a long service life. It provides consistent, efficient power transformation. This unit is a solid choice for modern utility grids. It meets the demands of both loop and radial network configurations.

Company Profile

PDDN Photoelectron Technology Co., Ltd. is one of the leading enterprises in power electronics technology and power products, which is fully involved in developing solar inverters, transformers, voltage regulators, distribution cabinets, thyristors, modules, diodes, heaters, and other electronic devices or semiconductors. We will be committed to providing users with high-quality, efficient products and considerate service.

It accepts payment via Credit Card, T/T, West Union, and Paypal. PDDN will ship the goods to customers overseas through FedEx, DHL, by sea, or by air. If you want high-quality 200kva 20kV ANSI/IEEE Standards Loop Feed Radial Feed Supply Pad Mounted Transformer , please send us inquiries; we will be here to help you.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

Storage Conditions

1) Store in a dry environment at room temperature.

2) Avoid damp and high temperature.

3) Use immediately after opening the inner packing bag.

5 FAQs of 200kva 20kV ANSI/IEEE Standards Loop Feed Radial Feed Supply Pad Mounted Transformer

Here are 5 FAQs for a 200kVA 20kV ANSI/IEEE Pad Mounted Transformer:

What is this transformer for? This transformer steps down high voltage electricity. It takes 20kV power from utility lines. It lowers the voltage to usable levels for homes or businesses. It’s built for loop feed or radial feed systems. Loop feed means power can come from two directions for reliability. Radial feed means power comes from one direction only. It sits on a concrete pad outside.

Why choose ANSI/IEEE standards? ANSI/IEEE standards are strict rules. They ensure the transformer is safe and reliable. These rules cover design, testing, and performance. Using this transformer means it meets North American utility requirements. It guarantees compatibility with other grid equipment. You get proven safety and consistent operation.

How is it protected? The transformer lives inside a tough metal enclosure. This enclosure is locked. It shields the electrical parts from weather, animals, and people. The case is strong steel. It protects against damage and unauthorized access. Safety is a top priority. The design prevents accidental contact with live parts.

What about installation? The transformer needs a solid, level concrete pad. This pad must support its weight. Proper clearances are vital around the unit. Follow the utility’s specific spacing rules. Correct grounding is absolutely critical. It protects against electrical faults. Always hire qualified utility or electrical professionals for installation. They know the local codes and safety procedures.

What maintenance is needed? These transformers are designed for low maintenance. They are very reliable. Regular visual checks are important. Look for oil leaks, damage, or rust. Keep the area around the transformer clear. Ensure vents are not blocked. More detailed checks involve oil testing. Utilities usually handle this maintenance. They check the oil condition and electrical parts periodically.

REQUEST A QUOTE

RELATED PRODUCTS

3 Phase Live Dead Front 34.5kV 13.8kv 500kVA 1000kVA 1250 Kva 1500kVA 2MVA Pad Mounted Transformer

10KV to 69KV 3KV 400KV Output Voltages Three-Phase Pad Mounted Transformer Substation 50HZ 60Hz Frequency

1mva 400kva 500kva 13.8kv 277/480y Pad-mounted Transformer with ul

Ce Pad Electric Transformer Coil Winding 1200w 50kva Transformer 3 Phase Step up Pad Mounted Transformer

3 Phase Pad Mount Transformer 13.2kv 6600v Pad Mounted 630kva 750kva 400kva 200kva Compact Transformer