Electronic Components Supplier | Transformers, Inductors, Inverters

PRODUCT PARAMETERS

Description

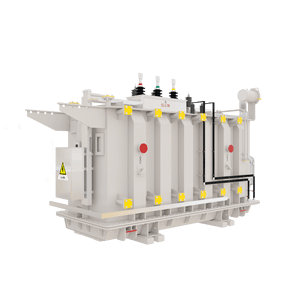

Overview of High Quality Electrical Power Oil Immersed Transformer

An oil-immersed transformer is a type of electrical transformer where the core and windings are submerged in an insulating oil. This oil serves two primary functions: it acts as a highly effective insulator between conductive parts and as a coolant to dissipate heat generated during operation. These transformers are robust, reliable, and highly efficient, making them the standard choice for high-voltage power distribution and transmission networks, typically installed outdoors in substations.

Features of High Quality Electrical Power Oil Immersed Transformer

- Effective Cooling: The insulating oil efficiently absorbs heat from the core and windings and transfers it to the radiator fins, allowing for natural or forced circulation and higher overload capacity.

- Superior Insulation: The oil provides much better dielectric strength than air, allowing for a more compact design for a given voltage rating and protecting against short circuits.

- Robust Construction: Designed for long-term, reliable operation (often 25-30 years) in harsh outdoor environments.

- Overload Capacity: Can handle temporary power overloads better than dry-type transformers due to the thermal mass and cooling properties of the oil.

- Protection System: Equipped with a conservator tank (to allow for oil expansion), breather (to absorb moisture from air), and protective relays (Buchholz relay) for internal fault detection.

- Cost-Effective: Generally more economical for high-power applications compared to dry-type transformers.

Specifications of High Quality Electrical Power Oil Immersed Transformer

High quality electrical power oil immersed transformers handle large amounts of electricity safely. They step voltage up or down efficiently. These units are built for tough conditions. They last a long time.

Voltage ratings are critical. Units manage primary and secondary voltages precisely. Common high voltage inputs are 11kV, 33kV, or 69kV. Outputs match specific needs, like 400V or 6.6kV. Frequency is usually 50Hz or 60Hz. Power ratings range widely. Smaller units handle 100kVA. Larger units manage 50MVA or more. Choose the right size for your load.

Cooling is vital. Mineral oil fills the tank. This oil insulates well. It also cools the core and windings effectively. Different cooling classes exist. ONAN uses natural oil flow and air. ONAF adds fans for forced air cooling. Higher ratings need stronger cooling methods. The oil level gauge is visible. A silica gel breather keeps moisture out.

Construction uses top materials. The core is laminated silicon steel. This reduces energy loss. Windings are copper or aluminum. Copper gives better conductivity. Aluminum is lighter. Both are tightly wound. The tank is welded steel. It holds pressure. Radiators attach to the outside. They help dissipate heat.

Efficiency matters. Good transformers lose very little power. They meet strict standards like IEC 60076. Low losses save money over years. Noise levels are controlled. Modern units run quietly. They comply with local noise rules.

Safety features are standard. A pressure relief device protects against overloads. Bushings provide safe external connections. Grounding points are clearly marked. The unit must be installed properly.

Testing proves performance. Factories do routine tests on every unit. This includes resistance checks and voltage ratio tests. Impedance and loss measurements are standard. Dielectric tests ensure insulation strength. Optional tests like temperature rise tests confirm cooling. Third-party certification is available. Quality control is strict throughout manufacturing. This ensures reliability day after day.

Applications of High Quality Electrical Power Oil Immersed Transformer

High quality electrical power oil immersed transformers handle electricity safely and reliably. They step down high voltage electricity from power lines to lower levels. This makes it usable for homes, businesses, and factories. These transformers are common everywhere electricity flows.

Power companies use them extensively. They install them in substations throughout the grid. They manage voltage levels efficiently over long distances. This ensures stable power delivery to entire towns and cities. Industrial facilities depend on them too. Factories, mines, and large plants need reliable power for heavy machinery. Oil immersed transformers provide this strong performance. They handle large loads constantly without failing.

Renewable energy projects also use these transformers. Solar farms and wind parks generate power far from cities. Transformers boost the voltage for efficient transmission to the grid. They connect green energy sources reliably. Critical infrastructure relies on them for backup power. Hospitals, data centers, and airports need uninterrupted electricity. Oil immersed transformers deliver consistent power during outages. They keep essential services running safely.

Commercial buildings use them for everyday operations. Shopping malls, office towers, and universities install them onsite. They receive high voltage power and step it down for internal use. This powers lighting, HVAC systems, and elevators smoothly. Transportation systems integrate them as well. Railways and subways need specialized power conversion. Transformers supply the right voltage for trains and signaling systems. Oil cooling keeps them running cool under pressure. This extends their lifespan significantly. Good insulation prevents dangerous electrical faults. They operate quietly and need minimal maintenance. This reduces long-term costs for owners. Their robust design withstands tough weather conditions. They perform reliably in heat, cold, and humidity.

Company Profile

PDDN Photoelectron Technology Co., Ltd. is one of the leading enterprises in power electronics technology and power products, which is fully involved in developing solar inverters, transformers, voltage regulators, distribution cabinets, thyristors, modules, diodes, heaters, and other electronic devices or semiconductors. We will be committed to providing users with high-quality, efficient products and considerate service.

It accepts payment via Credit Card, T/T, West Union, and Paypal. PDDN will ship the goods to customers overseas through FedEx, DHL, by sea, or by air. If you want high-quality High Quality Electrical Power Oil Immersed Transformer, please send us inquiries; we will be here to help you.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

Storage Conditions

1) Store in a dry environment at room temperature.

2) Avoid damp and high temperature.

3) Use immediately after opening the inner packing bag.

5 FAQs of High Quality Electrical Power Oil Immersed Transformer

People often ask us about high quality electrical power oil immersed transformers. Here are five common questions and their answers.

What exactly is an oil immersed transformer? It’s a device that changes electricity voltage levels. It uses special oil to insulate and cool its internal parts. The transformer sits inside a strong steel tank filled with oil. This setup handles large amounts of power safely.

Why use oil inside the transformer? Oil does two main jobs. It stops electrical sparks between parts. It also absorbs heat from the coils and core. The oil gets hot during operation. It carries that heat away. This keeps the transformer from getting too hot. Good cooling prevents damage.

How does the oil cooling system work? The hot oil naturally rises inside the tank. Cooler oil sinks. This movement creates a flow. The oil touches the tank walls. The walls release heat into the air. Bigger transformers often have extra cooling. They use radiators or fans. These help the oil cool down faster.

How long does this transformer usually last? A well-made oil immersed transformer can work for decades. Expect 25 years or more. Actual lifespan depends on several things. The build quality matters a lot. How hard it works matters too. Regular maintenance is crucial. The operating environment affects it. Proper care makes it last much longer.

What maintenance does it need? Check the oil level regularly. Test the oil quality often. Look for dirt or water in the oil. Bad oil can’t insulate or cool well. Inspect the tank for leaks. Listen for strange noises. Look for signs of overheating. Clean the cooling surfaces. Follow the manufacturer’s schedule. Good maintenance prevents failures.

REQUEST A QUOTE

RELATED PRODUCTS

500KVA 11KV/0.4 KV Distribution Transformer China Manufacturer

Factory S13 Oil Immersed Transformer Factory 200KVA Power Transformer 10kv/0.4

50KVA 11kv Suitable for High Temperature Three-phase Oil-immersed Outdoor Transformer

Distribution transformer 11KV 3 Phase Oil power Transformer China Manufacturer