Electronic Components Supplier | Transformers, Inductors, Inverters

PRODUCT PARAMETERS

Description

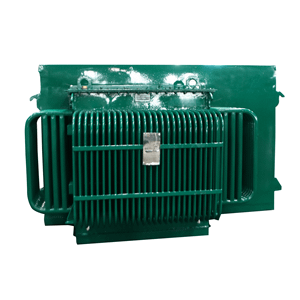

Overview of 350-2500kVA 35kv110kv Electronic Three-Phase Power Oil Immersed Transformer 480v Pad Mounted Distribution MV&HV Transformers

350-2500kVA 35kv110kv Electronic Three-Phase Power Oil Immersed Transformer 480v Pad Mounted Distribution MV&HV Transformers is an enclosed, ground-level electrical distribution transformer commonly used in underground (UG) power systems. It steps down primary high-voltage electricity (e.g., 15kV or 25kV) to a lower secondary voltage (e.g., 120/240V or 480V) for safe distribution to residential neighborhoods, commercial buildings, and industrial parks. Its robust, lockable steel enclosure makes it safe for public areas.

Features of 350-2500kVA 35kv110kv Electronic Three-Phase Power Oil Immersed Transformer 480v Pad Mounted Distribution MV&HV Transformers

Ground-Level Enclosure: A locked, tamper-resistant, weatherproof steel cabinet that protects the internal components and ensures public safety.

Underground Cable Connections: Designed for easy connection to underground primary (high-voltage) and secondary (low-voltage) cables via compartments with built-in bushings.

Compartmentalization: Separate, isolated compartments for high-voltage and low-voltage components, enhancing safety during maintenance.

Ventilation: Designed with louvers or other ventilation systems to allow for proper heat dissipation from the transformer core and coils.

Lifting Lugs: Integrated lifting lugs for easy and safe installation and replacement using a crane or hoist.

Tamper-proof Hardware: Lockable doors with special bolts to prevent unauthorized access.

Fused Switches: Often includes fused disconnect switches for circuit protection and safe isolation.

Pad Foundation: Installed on a concrete pad (“pad-mounted”) to provide a stable, level base.

Specifications of 350-2500kVA 35kv110kv Electronic Three-Phase Power Oil Immersed Transformer 480v Pad Mounted Distribution MV&HV Transformers

This 350-2500kVA electronic three-phase power transformer handles high voltage electrical energy. It tips down power from 35kV or 110kV systems to a useful 480V degree. Developed for pad mounting outdoors, it’s a dependable distribution solution.

The transformer makes use of oil immersion. This oil cools down the core and windings successfully. It additionally gives exceptional electrical insulation. This design makes certain steady procedure under hefty loads. The transformer stands up to requiring environmental problems.

Secret specs consist of a primary voltage of 35kV or 110kV. The second voltage is 480V. Capacity options variety extensively from 350kVA to 2500kVA. This covers diverse power demands. The cooling type is ONAN (Oil Natural, Air Natural). This implies all-natural oil circulation and air cooling job effectively.

The core makes use of high-grade electric steel. This reduces energy losses. Windings are generally copper or aluminum. They are precisely wound for optimum efficiency. A durable container homes the core and windings. This container is weatherproof and corrosion-resistant. It safeguards the inner components dependably.

These transformers consist of important protection attributes. Stress relief tools prevent tank overpressure. Temperature evaluates screen oil temperature frequently. Fluid level indications reveal oil quantity. Some models supply on-load faucet changers. This permits voltage change without detaching power.

The transformer fulfills global standards. It ensures security and reliability. Its design concentrates on reduced losses and high effectiveness. This saves energy expenses over its life-span. Upkeep requirements are normally low. It provides reliable solution for several years.

These pad-mounted transformers are ideal for different setups. They power industrial facilities dependably. They provide electrical power to huge industrial complicateds. They serve infrastructure projects successfully. They integrate into utility circulation networks effortlessly. They supply power where high voltage fulfills neighborhood needs.

Applications of 350-2500kVA 35kv110kv Electronic Three-Phase Power Oil Immersed Transformer 480v Pad Mounted Distribution MV&HV Transformers

This transformer handles big power jobs. It steps down high voltage electricity safely. The range is 350 to 2500 kVA. It takes input from 35kV or 110kV systems. It outputs at a standard 480 volts. This is a three phase unit. It uses oil for cooling and insulation inside its tank. You find it mounted on a concrete pad outdoors.

Its main job is feeding power to large facilities. Think factories needing lots of machinery. Or big commercial buildings like hospitals and data centers. Mines and oil refineries rely on this type too. It connects directly to the high voltage grid. It brings that power down to usable levels for equipment.

Utilities use it widely. It’s perfect for substations serving neighborhoods. It powers entire industrial parks. It connects renewable energy farms to the grid. Wind and solar sites need these transformers. They handle the power generated before sending it long distances.

The pad-mounted design is key. It sits securely outside. It connects easily to underground power lines. This keeps things safe and tidy. The robust tank protects the core and windings. Oil cooling ensures it runs reliably under heavy loads. It handles continuous operation in tough weather.

Specific places need this transformer. Large manufacturing plants depend on it. Water treatment facilities require its steady power. Major airports use it for critical systems. University campuses distribute power with it. Any large project needing bulk power at 480V uses this unit. It provides the crucial link between the high voltage grid and the end user’s equipment. This transformer delivers reliable power day and night.

Company Profile

PDDN Photoelectron Technology Co., Ltd. is one of the leading enterprises in power electronics technology and power products, which is fully involved in developing solar inverters, transformers, voltage regulators, distribution cabinets, thyristors, modules, diodes, heaters, and other electronic devices or semiconductors. We will be committed to providing users with high-quality, efficient products and considerate service.

It accepts payment via Credit Card, T/T, West Union, and Paypal. PDDN will ship the goods to customers overseas through FedEx, DHL, by sea, or by air. If you want high-quality 350-2500kVA 35kv110kv Electronic Three-Phase Power Oil Immersed Transformer 480v Pad Mounted Distribution MV&HV Transformers, please send us inquiries; we will be here to help you.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

Storage Conditions

1) Store in a dry environment at room temperature.

2) Avoid damp and high temperature.

3) Use immediately after opening the inner packing bag.

5 FAQs of 350-2500kVA 35kv110kv Electronic Three-Phase Power Oil Immersed Transformer 480v Pad Mounted Distribution MV&HV Transformers

Here are 5 key FAQs about our 350-2500kVA 35kV/110kV Electronic Three-Phase Power Oil Immersed Transformers (480V Pad Mounted Distribution MV&HV):

1. Are these transformers safe?

Safety is critical. These transformers use mineral oil for cooling and insulation. The oil is contained within a strong, sealed tank. The pad-mounted design places all high-voltage parts inside this secure enclosure. This keeps people safe. It prevents accidental contact with dangerous voltages. Proper grounding is essential. Always follow strict safety rules during installation and service.

2. How do we install them?

Installation needs a solid concrete pad. The pad must be perfectly level. Its size and strength must match the transformer’s weight. Ensure enough space around the unit. This space allows for safe operation. It allows for future maintenance access. Connections must be precise. Use the correct cables and terminations for 35kV or 110kV input and the 480V output. Hire qualified high-voltage electricians for this work.

3. What maintenance is needed?

Regular checks are vital. Monitor the oil level through the gauge. Look for any leaks immediately. Check the temperature indicators. Record these readings often. Test the oil quality periodically. This checks its insulating strength and moisture content. Inspect bushings, connections, and the tank exterior for damage or corrosion. Schedule professional inspections and testing annually. Follow the manufacturer’s maintenance schedule exactly.

4. What about oil leaks?

Oil leaks are serious. They create a fire hazard. They harm the environment. Our tanks are welded for maximum strength. We use high-quality seals. Still, leaks can happen from damage or worn seals. Report any oil leak right away. Stop the leak quickly. Clean up spilled oil following environmental regulations. Fix the cause of the leak before restarting the transformer.

5. How long do they last?

These transformers are built to last. Expect a service life of 25 to 40 years. Proper installation is the first step. Consistent maintenance is crucial. Protect the transformer from severe overloads. Protect it from lightning strikes and voltage surges. Operating conditions impact lifespan. Units in clean, moderate environments usually last longest. Units in harsh, dirty, or very hot locations may need more care and have a shorter life.

REQUEST A QUOTE

RELATED PRODUCTS

IEEE/ANSI IEC Standard 3150kva 12.47kv-480V Loop Feed Radial Feed Three Phase Pad Mounted transformers Pedestal Type

TK Switchgear Pad Mounted Transformer MV&HV Ring Main Unit RMU Switchgear Compact Substation

Solar Panel Use Photovoltaic Wind Power Generation Combined Transformer 1000kva Pad Mounted Transformer

Pad Mounted Transformer Electric transformers 13.2kV/23kV/35kV 75kVA/112.5kVA/ 150kVA/500kVA Pad Mounted Transformer

315kVA 1250 KVA 2500kVA 15 KV34.5kV 38.5kV Transformer High Voltage Wind Turbine Pad Mounted Transformer