Electronic Components Supplier | Transformers, Inductors, Inverters

PRODUCT PARAMETERS

Description

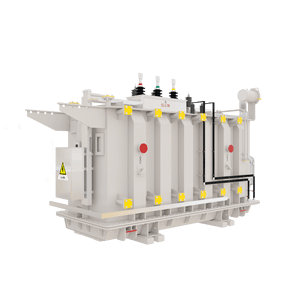

Overview of 15Kv 25Kv Transformer 500 Kva 630 Kva 1000 Kva Electrical Equipment Oil Immersed Transformer

An oil-immersed transformer is a type of electrical transformer where the core and windings are submerged in an insulating oil. This oil serves two primary functions: it acts as a highly effective insulator between conductive parts and as a coolant to dissipate heat generated during operation. These transformers are robust, reliable, and highly efficient, making them the standard choice for high-voltage power distribution and transmission networks, typically installed outdoors in substations.

Features of 15Kv 25Kv Transformer 500 Kva 630 Kva 1000 Kva Electrical Equipment Oil Immersed Transformer

- Effective Cooling: The insulating oil efficiently absorbs heat from the core and windings and transfers it to the radiator fins, allowing for natural or forced circulation and higher overload capacity.

- Superior Insulation: The oil provides much better dielectric strength than air, allowing for a more compact design for a given voltage rating and protecting against short circuits.

- Robust Construction: Designed for long-term, reliable operation (often 25-30 years) in harsh outdoor environments.

- Overload Capacity: Can handle temporary power overloads better than dry-type transformers due to the thermal mass and cooling properties of the oil.

- Protection System: Equipped with a conservator tank (to allow for oil expansion), breather (to absorb moisture from air), and protective relays (Buchholz relay) for internal fault detection.

- Cost-Effective: Generally more economical for high-power applications compared to dry-type transformers.

Specifications of 15Kv 25Kv Transformer 500 Kva 630 Kva 1000 Kva Electrical Equipment Oil Immersed Transformer

These transformers deal with high voltages like 15kV and 25kV. They can be found in usual power dimensions: 500kVA, 630kVA, and 1000kVA. This equipment makes use of oil for cooling and insulation. The core is constructed from top-notch electric steel. This reduces power loss. Copper or light weight aluminum windings bring the existing. Their style makes sure reliable power transfer.

The transformer rests inside a solid welded steel container. This container holds the shielding oil. It secures the interior parts. Radiators affix to the container. These radiators assist cool the oil naturally. Bigger units might require followers. Followers provide additional cooling power. This keeps temperature levels safe.

These transformers handle high voltage rises. They have solid insulation degrees. Basic Impulse Degree (BIL) rankings are high. This safeguards against lightning strikes. The oil degree is vital. An oil scale shows the degree clearly. Reduced oil triggers an alarm. Getting too hot is checked. Temperature level sensors turn on cautions. Stress relief devices prevent tank tear.

Setup alternatives are versatile. They function well on concrete pads outdoors. They fit inside substation buildings. They attach to overhead lines. They attach to underground cables. Terminals come. They are designed for very easy link. These devices serve numerous demanding work. They power plants. They provide huge buildings. They feed mining operations. They support energy substations. Reliability is essential. Efficiency is consistent under tons. Maintenance needs are simple. Regular checks make sure long service life.

Applications of 15Kv 25Kv Transformer 500 Kva 630 Kva 1000 Kva Electrical Equipment Oil Immersed Transformer

These 15kV and 25kV oil-immersed transformers (500kVA, 630kVA, 1000kVA) are vital electrical devices. They handle power distribution accurately. You discover them in lots of places needing strong voltage control.

Plant depend on them. Factories running heavy machinery call for stable power. These transformers step down high voltage from the grid. This powers motors, assembly lines, and large devices securely. They manage the considerable electric lots usual in manufacturing.

Energy substations use them frequently. Power business transmit electricity over cross countries at high voltage. These transformers reduce that voltage. Then, the electrical energy can feed safely into regional distribution networks. They are an important web link getting power to homes and companies.

Renewable energy jobs depend on them also. Huge solar farms or wind parks create power. This power usually needs stepping up for transmission. They likewise require stepping down where it links to the grid. These transformers take care of that voltage conversion effectively. They incorporate green source of power properly.

Mining procedures need durable power remedies. Remote websites utilize these transformers. They manage the requiring power demands of removal and handling equipment. The oil-immersed layout supplies necessary air conditioning. This is crucial in rough mining environments.

Business complicateds utilize them. Huge structures like mall or medical facilities have significant power needs. These transformers provide the required electrical energy. They ensure regular voltage levels throughout the center. Procedures stay smooth.

Infrastructure projects require them. Train systems need high-capacity transformers. They power electric trains and signaling systems accurately. The proper voltage is non-negotiable for safety and function.

They are built tough. The oil insulation gives exceptional cooling. It likewise protects interior components. This style guarantees long service life. It handles overloads much better than some dry kinds. Upkeep is uncomplicated. Operators can quickly examine oil levels and condition. This maintains the transformer running dependably for several years. They are a relied on solution for demanding electric circulation. Country power distribution networks likewise utilize them commonly. They boost voltage for long-distance transmission. After that, they lower it for local villages. This makes certain usable power reaches remote communities. Their sturdiness takes care of less steady grid problems often found in these areas.

Company Profile

PDDN Photoelectron Technology Co., Ltd. is one of the leading enterprises in power electronics technology and power products, which is fully involved in developing solar inverters, transformers, voltage regulators, distribution cabinets, thyristors, modules, diodes, heaters, and other electronic devices or semiconductors. We will be committed to providing users with high-quality, efficient products and considerate service.

It accepts payment via Credit Card, T/T, West Union, and Paypal. PDDN will ship the goods to customers overseas through FedEx, DHL, by sea, or by air. If you want high-quality 15Kv 25Kv Transformer 500 Kva 630 Kva 1000 Kva Electrical Equipment Oil Immersed Transformer , please send us inquiries; we will be here to help you.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

Storage Conditions

1) Store in a dry environment at room temperature.

2) Avoid damp and high temperature.

3) Use immediately after opening the inner packing bag.

5 FAQs of 15Kv 25Kv Transformer 500 Kva 630 Kva 1000 Kva Electrical Equipment Oil Immersed Transformer

What voltage levels do these transformers handle?

These transformers work with 15kV and 25kV systems. They step high voltage down for safer use. They handle incoming power at these levels.

Where are these oil transformers typically used?

They power large industrial sites. They supply factories, mines, and big buildings. Utilities use them in substations for power distribution. They are also good for renewable energy projects.

What are the main features of these oil-filled transformers?

These transformers are built tough. They have strong steel tanks. They use special insulating oil for cooling and protection. They are made to last a long time outdoors. They resist corrosion and weather damage.

How do these transformers stay cool?

Heat comes from electricity flowing inside. The oil absorbs this heat. The heat moves from the coils to the oil. The oil then carries heat to the tank walls. Air cools the tank surface. Bigger units might have fins or radiators for extra cooling.

What maintenance do these transformers need?

Regular checks are essential. Technicians test the insulating oil quality. They look for leaks or damage. They clean bushings and check connections. Internal parts need inspection every few years. Oil analysis predicts problems early.

REQUEST A QUOTE

RELATED PRODUCTS

TSTY 3 Phase Voltage Transformer Oil Immersed Transformer 11kv 33kv 50kva 100kva 200kva 300kva 220v to 380v Step up Transformer

Industrial Electrical Transformers 200kVA 315kVA 630kVA 10kV 11kV 0.4kV Three-Phase Oil-Immersed Transformer

66kV Oil Immersed Outdoor Type Current Transformer

1300kva 1300kw 15KV 33KV Trasformateur De Puissance Transformador De Potencia Oil Immersed Power Fully Sealed transformers

DC 35KV High Voltage Transformer For sale