Electronic Components Supplier | Transformers, Inductors, Inverters

PRODUCT PARAMETERS

Description

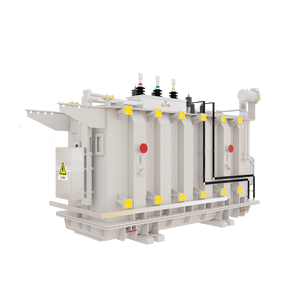

Overview of 50KVA 100KVA 150KVA 200KVA 250KVA 300KVA 400KVA 450KVA 500KVA 20KV Oil Immersed Electrical Power Distribution Transformer

An oil-immersed transformer is a type of electrical transformer where the core and windings are submerged in an insulating oil. This oil serves two primary functions: it acts as a highly effective insulator between conductive parts and as a coolant to dissipate heat generated during operation. These transformers are robust, reliable, and highly efficient, making them the standard choice for high-voltage power distribution and transmission networks, typically installed outdoors in substations.

Features of 50KVA 100KVA 150KVA 200KVA 250KVA 300KVA 400KVA 450KVA 500KVA 20KV Oil Immersed Electrical Power Distribution Transformer

- Effective Cooling: The insulating oil efficiently absorbs heat from the core and windings and transfers it to the radiator fins, allowing for natural or forced circulation and higher overload capacity.

- Superior Insulation: The oil provides much better dielectric strength than air, allowing for a more compact design for a given voltage rating and protecting against short circuits.

- Robust Construction: Designed for long-term, reliable operation (often 25-30 years) in harsh outdoor environments.

- Overload Capacity: Can handle temporary power overloads better than dry-type transformers due to the thermal mass and cooling properties of the oil.

- Protection System: Equipped with a conservator tank (to allow for oil expansion), breather (to absorb moisture from air), and protective relays (Buchholz relay) for internal fault detection.

- Cost-Effective: Generally more economical for high-power applications compared to dry-type transformers.

Specifications of 50KVA 100KVA 150KVA 200KVA 250KVA 300KVA 400KVA 450KVA 500KVA 20KV Oil Immersed Electrical Power Distribution Transformer

These power transformers deal with circulation voltages at 20 kilovolts. They come in dimensions from 50 kilovolt-amperes approximately 500 kilovolt-amperes. Typical rankings include 50, 100, 150, 200, 250, 300, 400, 450, and 500 kVA. The primary winding links to the 20kV distribution line. The second winding gives conventional reduced voltage outcome, generally 400 volts. This arrangement is ideal for tipping down high voltage for commercial sites or industrial buildings.

The transformer core utilizes state-of-the-art electric steel laminations. This reduces power losses. Windings are copper conductors. They are fully immersed in top quality mineral oil. The oil offers two objectives. It shields the windings. It also cools down the transformer properly. The durable steel storage tank confines whatever. It supplies security and includes the oil.

Conventional layouts feature all-natural oil blood circulation. Warmth rises normally. Radiator financial institutions attached to the tank assistance dissipate this heat. Bigger units, like the 400kVA to 500kVA designs, typically have corrugated container walls or extra radiators. This enhances the cooling area. All devices consist of crucial protection tools. These are pressure safety valve and oil degree evaluates. Basic lightning impulse endure degrees (BIL) are conventional for 20kV tools.

Manufacturing adheres to stringent international criteria. These are IEC or IEEE. Compliance guarantees integrity and safety and security. Efficiency targets fulfill IE2 or greater degrees. This implies low no-load losses and reduced lots losses. Minimized losses save power costs over the transformer’s lengthy life. The design concentrates on toughness and secure operation. Maintenance needs are easy.

These transformers are workhorses. They tip down voltage from the energy grid. They supply power to manufacturing facilities, huge facilities, real estate complicateds, and facilities projects. Their durable construction takes care of constant procedure. They are suitable for outdoor setup. Appropriate pad installing is necessary.

Applications of 50KVA 100KVA 150KVA 200KVA 250KVA 300KVA 400KVA 450KVA 500KVA 20KV Oil Immersed Electrical Power Distribution Transformer

These transformers step down high voltage power to safer, functional degrees. They’re necessary for powering big centers reliably. The 50KVA to 500KVA array covers lots of requiring circumstances. Manufacturing facilities rely upon them heavily. Machines, production line, and huge electric motors require consistent power. Transformers like the 150KVA or 200KVA devices handle this load well. Building websites use them too. Short-lived power for heavy equipment often comes with a 100KVA or 200KVA transformer. It powers tools and website illumination effectively.

Business buildings depend upon these transformers. Shopping center, workplace towers, and resorts require considerable power. A 300KVA, 400KVA, or 500KVA system manages lighting, HVAC, and lifts efficiently. Health centers are essential users. Nonstop power for life-saving tools is non-negotiable. Devices like the 250KVA or 450KVA make sure backup systems work flawlessly. Water therapy plants likewise utilize them. Pumping terminals and handling equipment run constantly. A durable 400KVA transformer supplies the necessary capacity.

The 20KV primary voltage suits several distribution networks. Oil immersion cools down the core and windings effectively. This style enables continuous procedure under hefty load. It’s a tested innovation recognized for sturdiness. Fire safety is a priority with these devices. They are built with fireproof materials and consist of oil leakages. Upkeep is uncomplicated. Technicians can easily inspect oil levels and connections. This guarantees lengthy life span and reduces downtime. Picking the right size matters. A 50KVA suits smaller sized commercial workshops. A 500KVA transformer powers large factories or data facilities. Matching ability to actual demand optimizes performance and price.

Company Profile

PDDN Photoelectron Technology Co., Ltd. is one of the leading enterprises in power electronics technology and power products, which is fully involved in developing solar inverters, transformers, voltage regulators, distribution cabinets, thyristors, modules, diodes, heaters, and other electronic devices or semiconductors. We will be committed to providing users with high-quality, efficient products and considerate service.

It accepts payment via Credit Card, T/T, West Union, and Paypal. PDDN will ship the goods to customers overseas through FedEx, DHL, by sea, or by air. If you want high-quality 50KVA 100KVA 150KVA 200KVA 250KVA 300KVA 400KVA 450KVA 500KVA 20KV Oil Immersed Electrical Power Distribution Transformer, please send us inquiries; we will be here to help you.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

Storage Conditions

1) Store in a dry environment at room temperature.

2) Avoid damp and high temperature.

3) Use immediately after opening the inner packing bag.

5 FAQs of 50KVA 100KVA 150KVA 200KVA 250KVA 300KVA 400KVA 450KVA 500KVA 20KV Oil Immersed Electrical Power Distribution Transformer

What size transformer do I need?

Check your total electrical load. Add up all equipment power needs. Include future expansion. We have 50kVA to 500kVA models. Choose a size slightly above your peak demand. This prevents overload.

Is this transformer oil-cooled?

Yes. It uses special insulating oil. The oil cools the transformer. It also insulates the internal parts. This design is reliable. It handles high power loads well.

What voltage does it work with?

This transformer is for 20kV systems. It steps down high voltage electricity. It delivers safer, usable voltage to buildings or factories. Confirm your incoming voltage matches 20kV.

How is it installed?

Mount it on a solid concrete pad outdoors. Ensure good ventilation space around it. Protect it from direct weather exposure if possible. Follow local electrical codes exactly. Hire qualified electricians.

How long does it last?

Expect 25-30 years with proper care. Schedule regular oil testing and maintenance. Keep the exterior clean. Check connections for tightness annually. Address small issues quickly. This prevents major failures.

REQUEST A QUOTE

RELATED PRODUCTS

30KVA 3 phase Oil immersed fully sealed transformer China Manufacturer

Three phase oil immersed distribution transformer China Manufacturer

Distribution transformer 11KV 22KV 33KV Oil Transformer China Manufacturer

30kva~2500kva voltage regulating distribution transformer China Manufacturer

1000kva 270v to 20kv oil distribution transformer