Electronic Components Supplier | Transformers, Inductors, Inverters

PRODUCT PARAMETERS

Description

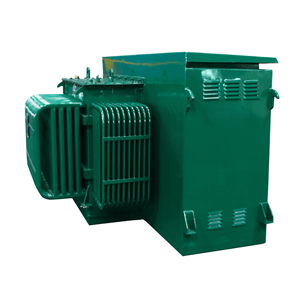

Overview of 1500kva 2000kva Standard Electric Factory 75Kva-5000Kva Three Phase Pad Mounted Transformer

1500kva 2000kva Standard Electric Factory 75Kva-5000Kva Three Phase Pad Mounted Transformer is an enclosed, ground-level electrical distribution transformer commonly used in underground (UG) power systems. It steps down primary high-voltage electricity (e.g., 15kV or 25kV) to a lower secondary voltage (e.g., 120/240V or 480V) for safe distribution to residential neighborhoods, commercial buildings, and industrial parks. Its robust, lockable steel enclosure makes it safe for public areas.

Features of 1500kva 2000kva Standard Electric Factory 75Kva-5000Kva Three Phase Pad Mounted Transformer

Ground-Level Enclosure: A locked, tamper-resistant, weatherproof steel cabinet that protects the internal components and ensures public safety.

Underground Cable Connections: Designed for easy connection to underground primary (high-voltage) and secondary (low-voltage) cables via compartments with built-in bushings.

Compartmentalization: Separate, isolated compartments for high-voltage and low-voltage components, enhancing safety during maintenance.

Ventilation: Designed with louvers or other ventilation systems to allow for proper heat dissipation from the transformer core and coils.

Lifting Lugs: Integrated lifting lugs for easy and safe installation and replacement using a crane or hoist.

Tamper-proof Hardware: Lockable doors with special bolts to prevent unauthorized access.

Fused Switches: Often includes fused disconnect switches for circuit protection and safe isolation.

Pad Foundation: Installed on a concrete pad (“pad-mounted”) to provide a stable, level base.

Specifications of 1500kva 2000kva Standard Electric Factory 75Kva-5000Kva Three Phase Pad Mounted Transformer

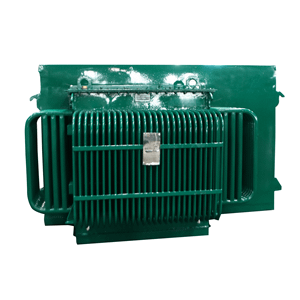

This factory makes standard three-phase pad mounted transformers. They handle many sizes from 75kVA up to 5000kVA. The 1500kVA and 2000kVA models are popular choices. These transformers are tough and reliable for outdoor use.

The 1500kVA unit handles 1500 kilovolt-amperes. The 2000kVA unit handles 2000 kilovolt-amperes. Both manage standard three-phase voltages. Primary voltages are usually 11kV, 22kV, or 33kV. Secondary voltages are typically 400V or 415V. Exact voltage specs match customer needs or local grids.

The transformer core uses high-grade grain-oriented silicon steel. This material reduces energy losses. Windings are made of copper or aluminum. The choice depends on the specific model and cost targets. The whole assembly sits inside a sturdy steel tank. This tank protects the internal parts from weather and damage. The tank is filled with high-quality insulating oil. This oil cools the transformer and provides electrical insulation.

These transformers meet important efficiency standards like DOE 2016 or IEC 60076. They are designed for low no-load losses and low load losses. This saves energy over the transformer’s long life. They pass strict routine tests and special tests. Tests include temperature rise tests, dielectric tests, and short-circuit tests. Certifications like ISO are common for this factory. Quality control is strict throughout manufacturing.

Installation is straightforward. The pad mounted design means they sit on a concrete slab. They connect directly to underground cables. Terminations are accessible through padlockable compartments. This enhances safety and security. The units need minimal maintenance. Regular checks on oil levels and bushings are usually sufficient.

These transformers are ideal for many places. They power commercial buildings, industrial plants, housing developments, and renewable energy sites. They deliver power reliably right where it’s needed.

Applications of 1500kva 2000kva Standard Electric Factory 75Kva-5000Kva Three Phase Pad Mounted Transformer

These transformers power many places needing reliable electricity. They step down high voltage from utility lines to safer levels buildings use. The 1500kVA and 2000kVA models handle significant loads. They are common in dense residential areas. Think large apartment complexes or housing developments. They supply entire neighborhoods safely.

Businesses rely on them too. Shopping centers need robust power for stores and lighting. Office buildings use them for computers, HVAC, and elevators. Industrial parks install them for machinery and lighting. They are practical for schools and hospitals requiring constant, stable power. Construction sites use them for temporary power before permanent setups.

The pad-mounted design sits directly on a concrete pad outdoors. This saves space. You don’t need a separate transformer building. The enclosure protects the internal components. It keeps people safe from high voltage. It also shields the transformer from weather and animals. Maintenance access is straightforward for technicians.

These units connect directly to underground power cables. Utilities install them easily. They fit well in urban settings or places with limited space. The range covers smaller needs like a few large houses (75kVA) up to very large industrial complexes (5000kVA). The 1500kVA and 2000kVA sizes are popular mid-range choices. They balance capacity and cost effectively for many projects. Reliability is key for continuous operation day and night.

Company Profile

PDDN Photoelectron Technology Co., Ltd. is one of the leading enterprises in power electronics technology and power products, which is fully involved in developing solar inverters, transformers, voltage regulators, distribution cabinets, thyristors, modules, diodes, heaters, and other electronic devices or semiconductors. We will be committed to providing users with high-quality, efficient products and considerate service.

It accepts payment via Credit Card, T/T, West Union, and Paypal. PDDN will ship the goods to customers overseas through FedEx, DHL, by sea, or by air. If you want high-quality 1500kva 2000kva Standard Electric Factory 75Kva-5000Kva Three Phase Pad Mounted Transformer, please send us inquiries; we will be here to help you.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

Storage Conditions

1) Store in a dry environment at room temperature.

2) Avoid damp and high temperature.

3) Use immediately after opening the inner packing bag.

5 FAQs of 1500kva 2000kva Standard Electric Factory 75Kva-5000Kva Three Phase Pad Mounted Transformer

People often ask about our standard factory 75KVA-5000KVA three-phase pad-mounted transformers. We focus on the popular 1500kVA and 2000kVA models here. These answers cover common points.

What size are the 1500kVA and 2000kVA transformers?

These units are large. They need significant space. The 1500kVA model is roughly 80 inches wide, 70 inches deep, and 75 inches tall. The 2000kVA model is slightly larger. Exact dimensions vary slightly based on specific design options. Always check the detailed drawings for your project.

How heavy are these transformers?

They are very heavy. The 1500kVA unit typically weighs between 8,000 and 9,500 pounds. The 2000kVA unit usually weighs between 9,500 and 11,000 pounds. Weight depends on the core and coil materials used. You need heavy lifting equipment for installation.

What safety features do they have?

Safety is critical. The steel tank is robust and tamper-resistant. It meets strict standards. The transformers include pressure relief devices. They have fault interrupters for protection. They are designed for safe operation in public areas. The locked compartments prevent unauthorized access.

Is installation difficult?

Installation requires planning. The site needs a solid concrete pad. The pad must be perfectly level. Access for a large crane is essential. Our units come pre-assembled. This reduces field work. Connection points are clearly marked. Qualified utility personnel must handle the electrical connections.

How much maintenance do they need?

These transformers are designed for low maintenance. They are completely sealed. No regular oil checks are needed. Routine inspections are still important. Look for physical damage. Check for oil leaks. Listen for unusual noises. Professional testing every few years is recommended.

REQUEST A QUOTE

RELATED PRODUCTS

45-6800kVA 12kV 15kV 24kV 36kV Customized Input UL Certified High Power Pad-Mounted Power Transformer Compact Substation

500kva Pad Mounted Transformer 10kv China Manufacturer

400kva 500 Kva 4000kva Three Phase Step Down Transformer 11kv To 400v 415v Pole Mounted Distribution Transformer

Pad Mounted Transformer Electric transformers 13.2kV/23kV/35kV 75kVA/112.5kVA/ 150kVA/500kVA Pad Mounted Transformer

Customized 15kVA American Single-Phase Pad Mounted Transformer 35kV/4160Y-120/240V 10kv Input 220v/110v Output 50Hz Frequency