Electronic Components Supplier | Transformers, Inductors, Inverters

PRODUCT PARAMETERS

Description

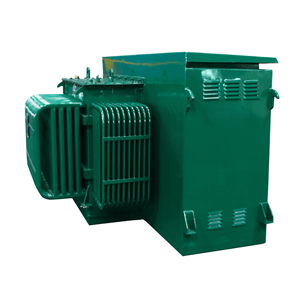

Overview of Three Phase 3150-3000-6300 10000 /24000 /25000 /20000 KVA 115KV/10KV/132KV Input 440V/380V/11KV Oil Immersed Power Transformer

Three Phase 3150-3000-6300 10000 /24000 /25000 /20000 KVA 115KV/10KV/132KV Input 440V/380V/11KV Oil Immersed Power Transformer is an enclosed, ground-level electrical distribution transformer commonly used in underground (UG) power systems. It steps down primary high-voltage electricity (e.g., 15kV or 25kV) to a lower secondary voltage (e.g., 120/240V or 480V) for safe distribution to residential neighborhoods, commercial buildings, and industrial parks. Its robust, lockable steel enclosure makes it safe for public areas.

Features of Three Phase 3150-3000-6300 10000 /24000 /25000 /20000 KVA 115KV/10KV/132KV Input 440V/380V/11KV Oil Immersed Power Transformer

Ground-Level Enclosure: A locked, tamper-resistant, weatherproof steel cabinet that protects the internal components and ensures public safety.

Underground Cable Connections: Designed for easy connection to underground primary (high-voltage) and secondary (low-voltage) cables via compartments with built-in bushings.

Compartmentalization: Separate, isolated compartments for high-voltage and low-voltage components, enhancing safety during maintenance.

Ventilation: Designed with louvers or other ventilation systems to allow for proper heat dissipation from the transformer core and coils.

Lifting Lugs: Integrated lifting lugs for easy and safe installation and replacement using a crane or hoist.

Tamper-proof Hardware: Lockable doors with special bolts to prevent unauthorized access.

Fused Switches: Often includes fused disconnect switches for circuit protection and safe isolation.

Pad Foundation: Installed on a concrete pad (“pad-mounted”) to provide a stable, level base.

Specifications of Three Phase 3150-3000-6300 10000 /24000 /25000 /20000 KVA 115KV/10KV/132KV Input 440V/380V/11KV Oil Immersed Power Transformer

This transformer handles high voltage power conversion. It steps down electricity from transmission levels to usable distribution voltages. Multiple models exist. Capacity options include 3150kVA, 3000kVA, 6300kVA, 10000kVA, 20000kVA, 24000kVA, and 25000kVA. It accepts high input voltages. Common inputs are 115kV, 132kV, or 10kV. Output voltages are lower. These outputs are typically 440V, 380V, or 11kV. This matches industrial and grid needs.

The transformer uses oil immersion. Oil cools the core and windings effectively. This design ensures stable operation under heavy loads. It prevents overheating. The tank is robust steel. It protects internal parts. All connections are secure. Terminals are clearly marked for safety. Installation follows standard practices.

Safety features are included. A pressure relief device activates if needed. It vents excess pressure safely. An oil level gauge shows the coolant amount. A silica gel breather keeps moisture out. This protects the oil quality. Temperature monitoring is possible. Gauges track oil temperature continuously. This helps prevent damage.

The core uses high-grade steel. This minimizes energy loss. Windings are copper. Copper conducts electricity well. This design ensures high efficiency. Losses are kept low. It saves energy over time. The transformer is built for reliability. It endures tough conditions. Long service life is expected.

Maintenance requirements are standard. Regular oil checks are necessary. Condition monitoring is recommended. This unit serves large power users. Factories, substations, and utilities use it. It powers heavy machinery and entire facilities. Performance meets industry standards. Specifications confirm voltage handling. They confirm capacity and insulation levels. Construction follows safety regulations.

Applications of Three Phase 3150-3000-6300 10000 /24000 /25000 /20000 KVA 115KV/10KV/132KV Input 440V/380V/11KV Oil Immersed Power Transformer

This power transformer handles big electricity jobs. It steps down high voltages for everyday use. The input side takes 115KV, 10KV, or 132KV power. The output side delivers safer 440V, 380V, or 11KV power. Different models offer 3150KVA, 3000KVA, 6300KVA, 10000KVA, 20000KVA, 24000KVA, or 25000KVA capacity. This range suits many demanding situations.

Factories need these transformers constantly. Heavy machinery requires stable, high-power 440V or 380V supply. This unit delivers that reliably. Mining operations depend on robust power for equipment. This transformer provides it. Oil refineries use complex processes needing steady voltage. This transformer ensures it.

Power substations rely on these units. They connect the high-voltage grid to local distribution networks. The 11KV output feeds smaller transformers serving neighborhoods. Renewable energy projects use them too. Large solar farms or wind installations generate high voltage. This transformer steps it down for grid connection.

Large buildings need significant power. Hospitals, universities, and airports use these transformers. They manage the main power intake from the utility. They distribute power safely throughout the facility. Water treatment plants are critical infrastructure. Consistent power is essential. This transformer guarantees it.

The oil-immersed design is key. Oil cools the core and windings effectively. This prevents overheating during heavy loads. Oil also provides excellent electrical insulation. This enhances safety and longevity. These transformers are built tough for outdoor use. They withstand harsh weather conditions. They require minimal maintenance.

This transformer offers reliable voltage conversion. It powers essential industries and infrastructure. Its robust construction ensures long service life. It keeps electricity flowing safely where large power demands exist.

Company Profile

PDDN Photoelectron Technology Co., Ltd. is one of the leading enterprises in power electronics technology and power products, which is fully involved in developing solar inverters, transformers, voltage regulators, distribution cabinets, thyristors, modules, diodes, heaters, and other electronic devices or semiconductors. We will be committed to providing users with high-quality, efficient products and considerate service.

It accepts payment via Credit Card, T/T, West Union, and Paypal. PDDN will ship the goods to customers overseas through FedEx, DHL, by sea, or by air. If you want high-quality Three Phase 3150-3000-6300 10000 /24000 /25000 /20000 KVA 115KV/10KV/132KV Input 440V/380V/11KV Oil Immersed Power Transformer, please send us inquiries; we will be here to help you.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

Storage Conditions

1) Store in a dry environment at room temperature.

2) Avoid damp and high temperature.

3) Use immediately after opening the inner packing bag.

5 FAQs of Three Phase 3150-3000-6300 10000 /24000 /25000 /20000 KVA 115KV/10KV/132KV Input 440V/380V/11KV Oil Immersed Power Transformer

What exactly is this transformer?

This is a three-phase oil-immersed power transformer. It changes high voltage electricity to lower voltage levels. It handles large power capacities: 3150 KVA, 3000 KVA, 6300 KVA, 10000 KVA, 24000 KVA, 25000 KVA, 20000 KVA. It takes input power at 115KV, 10KV, or 132KV. It outputs power at 440V, 380V, or 11KV. The oil inside cools the transformer effectively.

Where is this transformer typically used?

It’s built for heavy-duty industrial applications. Think large factories, major mining operations, big water treatment plants. It powers entire facilities needing massive amounts of electricity. It connects high-voltage transmission lines to the lower voltage equipment used on-site.

What are its main advantages?

Its key strength is handling very high power levels reliably. The oil cooling ensures stable operation under heavy loads. It offers multiple input and output voltage combinations. This flexibility suits various national grid standards and specific site needs. Its robust design ensures long service life in tough conditions.

How is it installed and connected?

Installation requires expert electrical engineers and certified technicians. The site must have a strong foundation. Proper lifting equipment is essential due to its weight and size. Connection follows strict safety protocols. Technicians must verify the correct input and output terminals. They must ensure all grounding is perfect. Testing happens before energizing the transformer.

What maintenance is needed?

Regular maintenance is critical for safety and performance. Technicians check the oil level and quality often. They test the oil for breakdown and moisture. They inspect bushings, connections, and cooling systems. They look for leaks or damage. Scheduled professional servicing extends its lifespan and prevents failures.

REQUEST A QUOTE

RELATED PRODUCTS

400kva 500 Kva 4000kva Three Phase Step Down Transformer 11kv To 400v 415v Pole Mounted Distribution Transformer

Three Phase 13.8kv 225kva 750 Kva 1500kva Best American Box Pad Mounted Transformer

Customized 1250kva 1600kva 2000kva Photovoltaic Power Generation 10KV 35KV Pad Mounted Substation Transformer

Small Electrical Transformer 50kva 100kva 200kva Power Amplifier Transformer

200kVA 15kV American Style Three-Phase Pad-Mounted Instrument Transformer 50Hz Frequency and 35kV Input Voltage IEEE/Certified