Electronic Components Supplier | Transformers, Inductors, Inverters

PRODUCT PARAMETERS

Description

Overview of 1 Ton Capacity Iron Steel Small Induction Melting Furnace for Casting

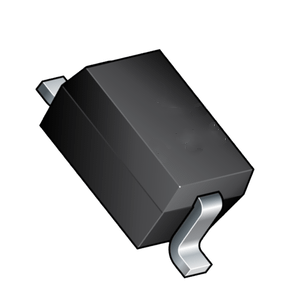

Thyristor is a solid-state semiconductor device composed of four layers of alternating P- and N-type materials. It functions as a bistable switch, conducting current only when triggered by a gate signal, and remains conducting until the voltage across it drops below a certain threshold. Thyristors are widely used for controlling high-power electrical circuits, offering efficient and reliable performance in various industrial and electronic applications.

Features of 1 Ton Capacity Iron Steel Small Induction Melting Furnace for Casting

- High current and voltage handling capabilities

- Low on-state voltage drop, reducing power loss

- Fast switching speeds for precise control

- Latching behavior: once triggered, remains conducting without continuous gate signal

- Robust and durable design suitable for harsh environments

- Available in various types (e.g., SCR, TRIAC, GTO) for specific needs

(1 Ton Capacity Iron Steel Small Induction Melting Furnace for Casting)

Specifications of 1 Ton Capacity Iron Steel Small Induction Melting Furnace for Casting

This 1 lot capability induction melting furnace effectively thaws iron and steel for spreading. It takes care of as much as 1000 kg of metal per cycle. The heater utilizes electromagnetic induction for heating. This process warms metal swiftly inside the heater crucible.

The heater body features a strong steel shell. Inside sits an unique refractory lining. This lining withstands extreme warm and molten metal. The heating system runs utilizing tool frequency power. This offers quick, efficient melting. Melting times differ relying on the steel type. The heating system attains high melting temperatures continually.

Procedure requires a compatible tool frequency power supply unit. The power supply controls the melting process. Operators manage the heater utilizing a control board. This panel presents key specifications like temperature level and power. Operators monitor the melting procedure closely. They can change setups as required for optimum outcomes.

The heating system includes a durable turning system. Employees turn the heater to put liquified metal. Turning usages hydraulic or electric systems. Safety and security is a priority. The heating system includes water cooling for important parts. This protects against getting too hot during operation. Security alarms turn on if cooling water flow stops. Other alarm systems signal abnormal conditions like heat or electric mistakes.

The furnace crucible holds the liquified steel. Crucibles are changeable. Routine upkeep guarantees long heater life. Operators examine the refractory lining usually. They replace it when wear becomes considerable. Appropriate upkeep keeps the heating system trusted.

(1 Ton Capacity Iron Steel Small Induction Melting Furnace for Casting)

Applications of 1 Ton Capacity Iron Steel Small Induction Melting Furnace for Casting

This 1 ton iron steel induction melting heating system thaws metal quick. It makes use of electricity for heating. The heater manages one metric ton of iron or steel charge. It works well for little shops. It functions well for workshops doing steel spreading.

You melt scrap steel first. You melt pig iron. You thaw steel returns. The heater obtains the metal fluid warm. After that you put this fluid steel right into mold and mildews. You make cast iron parts this way. You make steel castings in this manner. The procedure is efficient. It utilizes much less power than larger heating systems. It thaws metal rapidly. This benefits tiny batch manufacturing.

Foundries utilize this heater for industrial components. You cast pump bodies. You cast valve real estates. You cast maker elements. You cast equipment spaces. You require high quality spreadings. This heater provides precise temperature control. You prevent melting the steel. You obtain constant outcomes. It deals with different steel grades.

Art shops use it as well. You cast metal sculptures. You cast decorative products. You cast architectural items. The furnace is the appropriate size for these jobs. You thaw only what you require. You save product. You save power.

Service centers utilize this heating system. They reprise damaged spreadings. They reprise used parts. You don’t need a gigantic heating system for this. This load system fits the job. It thaws steel quick for repair work. Manufacturing downtime is less.

Some shops use it for alloy manufacturing. You include components to the thaw. You make special iron alloys. You make unique steel qualities. The heating system blends the melt well. You get uniform alloy make-up. Small batches are easy.

The heater is small. It fits smaller spaces. Operation is fairly easy. Training time is much shorter. It supplies a reduced cost entry factor. Small companies can manage it. It provides a useful melting service. It makes little range metal casting feasible. It makes small scale steel casting efficient.

Company Profile

PDDN Photoelectron Technology Co., Ltd. is one of the leading enterprises in power electronics technology and power products, which is fully involved in developing solar inverters, transformers, voltage regulators, distribution cabinets, thyristors, modules, diodes, heaters, and other electronic devices or semiconductors. We will be committed to providing users with high-quality, efficient products and considerate service.

It accepts payment via Credit Card, T/T, West Union, and Paypal. PDDN will ship the goods to customers overseas through FedEx, DHL, by sea, or by air. If you want high-quality 1 Ton Capacity Iron Steel Small Induction Melting Furnace for Casting, please send us inquiries; we will be here to help you.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

Storage Conditions

1) Store in a dry environment at room temperature.

2) Avoid damp and high temperature.

3) Use immediately after opening the inner packing bag.

5 FAQs of 1 Ton Capacity Iron Steel Small Induction Melting Furnace for Casting

1 Ton Capacity Iron Steel Small Induction Melting Furnace for Casting – FAQs

What metal can this furnace melt?

This furnace melts iron and steel. It works well for casting jobs. The furnace uses electromagnetic induction heating. This method heats metal fast and efficiently. It’s perfect for small foundries needing 1-ton batches.

How do I start melting metal?

Turn on the main power supply. Switch on the cooling water system. Make sure water flows correctly. Load your scrap iron or steel into the crucible. Close the furnace lid securely. Power up the induction coil. The metal heats quickly. Monitor the temperature display. Pour the molten metal when ready.

How fast does it melt one ton?

Melting speed depends on the metal type. It depends on the starting temperature too. For iron or steel, expect about 45 minutes per ton. The furnace heats metal very directly. This makes it faster than older furnace types. You save time on each melt cycle.

What power supply does it need?

This furnace needs strong electricity. Typically, it requires a 3-phase power source. Voltage is usually 380V or 415V. Power consumption is high during melting. Check your local power capacity first. The furnace needs stable voltage. Unstable power affects performance.

Is this furnace safe to operate?

Safety is important. The furnace has key safety features. The water cooling system prevents overheating. It protects the coil and parts. The furnace body has insulation. This shields operators from heat. Always wear protective gear. Follow the operating manual exactly. Keep the area dry. Water near electricity is dangerous.

How often replace the crucible?

Crucible life varies. It depends on melting temperature. It depends on how many batches you run. Crucibles wear out over time. Inspect the crucible regularly. Look for cracks or thin spots. Replace it immediately if damaged. A typical crucible lasts 60-80 heats. Crucible cost is part of regular operation.

(1 Ton Capacity Iron Steel Small Induction Melting Furnace for Casting)

REQUEST A QUOTE

RELATED PRODUCTS

helical unidirectional bolt thyristor

IC CHIP Diodes Thyristors Transistors

High Power Silicon Controlled TRIAC THYRISTOR Modules BTA41 BTA26 BTA16 Packaged Power Drivers

thyristor SCR thyristor cheap

SCR THYRISTOR DIODE MODULES IGBT POWER MODULE In stock IGBT MODULE chip Electronic components