Electronic Components Supplier | Transformers, Inductors, Inverters

PRODUCT PARAMETERS

Description

Overview of 100KG for Foundrie Factory Scrap Steel /Iron Recycling Induction Melting Furnace for Industrial Electric Stove

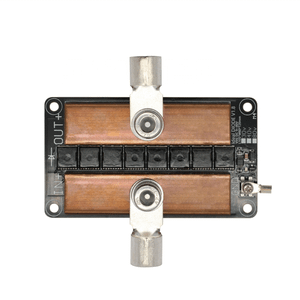

Thyristor is a solid-state semiconductor device composed of four layers of alternating P- and N-type materials. It functions as a bistable switch, conducting current only when triggered by a gate signal, and remains conducting until the voltage across it drops below a certain threshold. Thyristors are widely used for controlling high-power electrical circuits, offering efficient and reliable performance in various industrial and electronic applications.

Features of 100KG for Foundrie Factory Scrap Steel /Iron Recycling Induction Melting Furnace for Industrial Electric Stove

- High current and voltage handling capabilities

- Low on-state voltage drop, reducing power loss

- Fast switching speeds for precise control

- Latching behavior: once triggered, remains conducting without continuous gate signal

- Robust and durable design suitable for harsh environments

- Available in various types (e.g., SCR, TRIAC, GTO) for specific needs

(100KG for Foundrie Factory Scrap Steel /Iron Recycling Induction Melting Furnace for Industrial Electric Stove)

Specifications of 100KG for Foundrie Factory Scrap Steel /Iron Recycling Induction Melting Furnace for Industrial Electric Stove

This 100KG induction melting heater melts scrap steel and iron quickly. Factories use it daily. It handles 100 kgs of metal each cycle. That’s a good dimension for smaller stores or batch work. The heating system uses strong electric induction heating. This approach thaws metal rapidly and successfully. It saves power contrasted to older heating system kinds. You feed scrap steel or iron items straight right into it. The heater transforms the scrap into liquid steel prepared for spreading. It needs industrial power. A 380V electric supply is basic. The power input is around 160KW. This offers the intense heat needed. The heater operates at tool frequency. This regularity gives outstanding control over the melting process. Temperature control is accurate. You can establish the exact melt temperature level required. The major fusion is a challenging steel crucible. It has an unique refractory lining within. This lining resists the severe warm and molten steel. The furnace body makes use of heavy steel plate construction. This makes it stiff and resilient. The system consists of water-cooling systems. Key components like the induction coil and power cables need cooling. Water moves through them frequently. This stops getting too hot during lengthy thaws. Operation is uncomplicated. Employees fill scrap steel into the top. They close the lid firmly. Then they begin the melting cycle. The steel heats up rapidly. Checking the procedure is basic. Operators inspect the temperature level screen. They see when the melt is full. Safety functions are integrated in. These shield operators and the tools. The heater is developed for hard manufacturing facility conditions. It handles continual melting changes. Upkeep is developed to be convenient. Changing the crucible cellular lining is a common job. The unit is reliable for reusing scrap metal into usable product. It turns waste into important liquid steel or iron.

(100KG for Foundrie Factory Scrap Steel /Iron Recycling Induction Melting Furnace for Industrial Electric Stove)

Applications of 100KG for Foundrie Factory Scrap Steel /Iron Recycling Induction Melting Furnace for Industrial Electric Stove

This heater melts scrap steel and iron fast. It manages 100kg sets. Factories utilize it daily. Recycling old steel comes to be straightforward. The procedure starts with packing scrap. Workers placed steel pieces or iron little bits inside. The heating system warms them swiftly utilizing electrical power. This is induction home heating. It melts metal successfully. No flames touch the steel straight. This makes points more secure inside the manufacturing facility.

The heater gets extremely hot extremely fast. This conserves power. It also saves time. Factories require to melt steel swiftly. This equipment does that task well. It helps all type of scrap. Old car parts, machinery bits, construction steel items are all suitable. The furnace transforms them right into liquid metal. This liquid metal is ready for casting new parts. Manufacturing facilities pour it into mold and mildews. They make brand-new products.

Procedure is straightforward. Workers regulate it easily. The furnace layout is durable. It handles challenging commercial use. Maintenance demands are low. This conserves money long-term. Safety is necessary. The heating system has safety features. It aids protect against crashes. Altering batches fasts. Employees empty the melted steel quick. They pack the next scrap bill right away. Downtime is marginal. Production maintains moving.

Company Profile

PDDN Photoelectron Technology Co., Ltd. is one of the leading enterprises in power electronics technology and power products, which is fully involved in developing solar inverters, transformers, voltage regulators, distribution cabinets, thyristors, modules, diodes, heaters, and other electronic devices or semiconductors. We will be committed to providing users with high-quality, efficient products and considerate service.

It accepts payment via Credit Card, T/T, West Union, and Paypal. PDDN will ship the goods to customers overseas through FedEx, DHL, by sea, or by air. If you want high-quality 100KG for Foundrie Factory Scrap Steel /Iron Recycling Induction Melting Furnace for Industrial Electric Stove, please send us inquiries; we will be here to help you.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

Storage Conditions

1) Store in a dry environment at room temperature.

2) Avoid damp and high temperature.

3) Use immediately after opening the inner packing bag.

5 FAQs of 100KG for Foundrie Factory Scrap Steel /Iron Recycling Induction Melting Furnace for Industrial Electric Stove

What scrap metals can this furnace melt?

This furnace melts steel and iron scrap. It handles common foundry leftovers like cuttings and old machine parts. Avoid materials with hazardous coatings. Clean scrap gives best results.

How much metal can it melt per hour?

Expect about 100 kilograms per hour using steel or iron scrap. Actual speed depends on scrap type and density. Consistent feeding helps maintain melting speed. Power settings also affect melt time.

What power supply does it need?

This furnace requires 3-phase industrial power. Standard voltage is 380V. Check your local power specs match the furnace specs. Sufficient power is critical for stable operation.

Is it easy for workers to use?

Yes, the controls are straightforward. Workers learn it fast. The digital panel shows temperature and power. Basic training covers starting, pouring, and shutdown. Safety steps are simple to follow.

What safety systems are included?

The furnace has essential safety. It includes overheat protection. It has water cooling monitoring. Emergency stop buttons are fitted. Always follow the manual’s safety rules. Wear protective gear near the furnace.

(100KG for Foundrie Factory Scrap Steel /Iron Recycling Induction Melting Furnace for Industrial Electric Stove)

REQUEST A QUOTE

RELATED PRODUCTS

Capsule Type Phase Control Thyristor SCR for Railway

Electronic components IC Chips mosfet transistor diode IGBT Power module IGBT MODULE

New and Original High-Power Thyristor Switch Fast Switching Thyristor Transmission and Distribution Equipment

Thyristor stud types of diode stud thyristor

Medium Frequency Metal Induction Heating Furnace for Steel Bars