Electronic Components Supplier | Transformers, Inductors, Inverters

PRODUCT PARAMETERS

Description

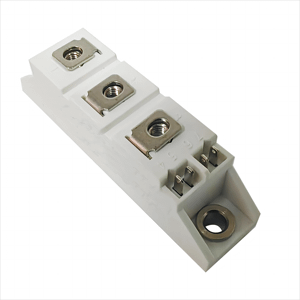

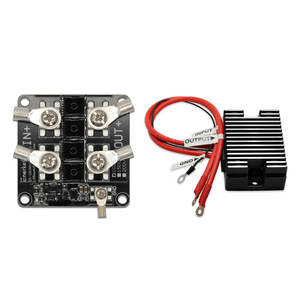

Overview of 200A 300V Thyristor Controlled Rectifier for Anodic Electrophoretic Coating

Thyristor is a solid-state semiconductor device composed of four layers of alternating P- and N-type materials. It functions as a bistable switch, conducting current only when triggered by a gate signal, and remains conducting until the voltage across it drops below a certain threshold. Thyristors are widely used for controlling high-power electrical circuits, offering efficient and reliable performance in various industrial and electronic applications.

Features of 200A 300V Thyristor Controlled Rectifier for Anodic Electrophoretic Coating

- High current and voltage handling capabilities

- Low on-state voltage drop, reducing power loss

- Fast switching speeds for precise control

- Latching behavior: once triggered, remains conducting without continuous gate signal

- Robust and durable design suitable for harsh environments

- Available in various types (e.g., SCR, TRIAC, GTO) for specific needs

(200A 300V Thyristor Controlled Rectifier for Anodic Electrophoretic Coating)

Specifications of 200A 300V Thyristor Controlled Rectifier for Anodic Electrophoretic Coating

This thyristor controlled rectifier powers anodic electrophoretic finishing processes. It delivers a stable DC current. The system supplies 200 Amps optimal result. It gets to 300 Volts DC optimum. Exact control over voltage and present is essential. This rectifier attains that. It makes use of sophisticated thyristor modern technology. This technology handles power circulation accurately. Stable outcome is crucial for uniform layer quality. This rectifier makes sure very little surge. Low surge avoids finishing flaws. Operators can establish precise parameters. Voltage and current restrictions are adjustable. This protects the finishing bathroom and components. The system reacts swiftly to changes. Quick response maintains regular conditions. Process security enhances substantially. The rectifier is constructed for challenging commercial settings. It has a tough room. Air air conditioning maintains parts running safely. Inner temperatures stay within risk-free restrictions. Trustworthy procedure is the outcome. Upkeep needs are lowered. The device links quickly to existing coating lines. Criterion analog and digital user interfaces are consisted of. Push-button control and surveillance are possible. Safety attributes secure workers and devices. Overcurrent and overtemperature security are basic. Short-circuit protection is included. Electric seclusion satisfies safety guidelines. The rectifier lugs CE and RoHS qualifications. Conformity with worldwide criteria is ensured. Installment is simple. Clear documentation supports arrangement and procedure. Technical support is readily available. This power supply improves covering performance. Consistent outcomes are accomplished set after set. Power usage is enhanced. Manufacturing prices reduce.

(200A 300V Thyristor Controlled Rectifier for Anodic Electrophoretic Coating)

Applications of 200A 300V Thyristor Controlled Rectifier for Anodic Electrophoretic Coating

This 200A 300V Thyristor Controlled Rectifier powers anodic electrophoretic covering systems. Anodic electrocoating down payments paint onto metal components submerged in a bathroom. The part works as the anode. A controlled DC current drives the process. Precise voltage and present control are important. This rectifier provides that control.

Thyristor modern technology takes care of the power conversion. It changes the DC output voltage smoothly. This happens really quick. Consistent finishing density outcomes. Parts get uniform paint insurance coverage. Side security enhances. This prevents slim areas. Rust resistance rises. The finish high quality fulfills high criteria.

The rectifier deals with demanding commercial atmospheres. It powers finishing lines for automobile components. Automotive components like structures use this process. Steel furniture suppliers depend on it. Home appliance manufacturers layer washing machine drums or fridge shelfs. Industrial devices benefits as well. Any type of conductive metal needing sturdy paint utilizes anodic electrocoating.

Voltage stability is essential throughout finish. This rectifier keeps tight voltage control. Current ramps up gently. This prevents first coating defects. The procedure runs smoothly. Operators established the specific voltage required. The thyristor reacts instantly. Finishing specifications remain within spec.

Power effectiveness matters. The thyristor design minimizes power loss. Much less power is thrown away. Operating costs reduce. The rectifier operates dependably shift after change. Downtime lowers. Manufacturing output remains high. Regular power implies consistent coatings. Fewer declines happen. Paint use becomes more effective.

This unit gives the durable, specific DC power anodic electrocoating needs. It makes sure premium, durable coatings on diverse metal products.

Company Profile

PDDN Photoelectron Technology Co., Ltd. is one of the leading enterprises in power electronics technology and power products, which is fully involved in developing solar inverters, transformers, voltage regulators, distribution cabinets, thyristors, modules, diodes, heaters, and other electronic devices or semiconductors. We will be committed to providing users with high-quality, efficient products and considerate service.

It accepts payment via Credit Card, T/T, West Union, and Paypal. PDDN will ship the goods to customers overseas through FedEx, DHL, by sea, or by air. If you want high-quality 200A 300V Thyristor Controlled Rectifier for Anodic Electrophoretic Coating, please send us inquiries; we will be here to help you.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

Storage Conditions

1) Store in a dry environment at room temperature.

2) Avoid damp and high temperature.

3) Use immediately after opening the inner packing bag.

5 FAQs of 200A 300V Thyristor Controlled Rectifier for Anodic Electrophoretic Coating

Here are five common questions about our 200A 300V Thyristor Controlled Rectifier for Anodic Electrophoretic Coating:

What is this rectifier for?

This unit changes AC power into DC power. It supplies the electrical current needed for anodic electrophoretic coating. The thyristors give precise control over the voltage and current.

Why use it for anodic coating?

Anodic coating needs stable DC power. This rectifier gives that stable power. Precise control is vital. It affects how well the coating sticks to the metal part. It changes the coating thickness and quality. This rectifier does that job reliably.

How does it improve coating quality?

The thyristor control allows fine adjustments. Operators set the exact voltage and current needed. This keeps the coating process consistent. Consistent electrical conditions mean uniform coating results every time. Good coating adhesion happens.

What are its main features?

It handles 200 Amps of current continuously. It works up to 300 Volts DC. The thyristor design makes it efficient. It responds fast to control changes. Built-in safety protects against overloads or shorts. It is designed for tough industrial environments.

What if my line voltage changes?

This rectifier compensates for input voltage changes. It keeps the output DC voltage steady. Steady voltage is critical for coating quality. Fluctuations cause bad coating results. This unit prevents those problems.

(200A 300V Thyristor Controlled Rectifier for Anodic Electrophoretic Coating)

REQUEST A QUOTE

RELATED PRODUCTS

Power Factor Save Capacitor & Reactor 7% Harmonic Filtering Capacitor Thyristor Switching Control Reactive Power Compensator

Disc type SCR / phase control thyristor / fast thyristor

KK KP Thyristor for Power Rectifier Power Supply of Induction Furnace

New and Original Thyristor Switch High-Power Thyristor Switch Industries Electrical Products

MIG-350 Thyristor Control Inverter Gas Shielded Manual Metal Arc Welding Machine