Electronic Components Supplier | Transformers, Inductors, Inverters

PRODUCT PARAMETERS

Description

Overview of 500kg 750kg 1000kg 1 Ton Brass Copper Iron Steel Melting Furnace Industrial Furnace Electric Furnace

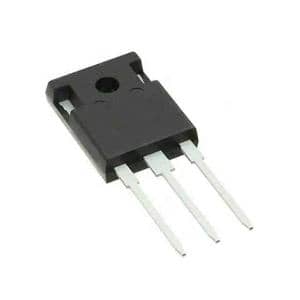

Thyristor is a solid-state semiconductor device composed of four layers of alternating P- and N-type materials. It functions as a bistable switch, conducting current only when triggered by a gate signal, and remains conducting until the voltage across it drops below a certain threshold. Thyristors are widely used for controlling high-power electrical circuits, offering efficient and reliable performance in various industrial and electronic applications.

Features of 500kg 750kg 1000kg 1 Ton Brass Copper Iron Steel Melting Furnace Industrial Furnace Electric Furnace

- High current and voltage handling capabilities

- Low on-state voltage drop, reducing power loss

- Fast switching speeds for precise control

- Latching behavior: once triggered, remains conducting without continuous gate signal

- Robust and durable design suitable for harsh environments

- Available in various types (e.g., SCR, TRIAC, GTO) for specific needs

(500kg 750kg 1000kg 1 Ton Brass Copper Iron Steel Melting Furnace Industrial Furnace Electric Furnace)

Specifications of 500kg 750kg 1000kg 1 Ton Brass Copper Iron Steel Melting Furnace Industrial Furnace Electric Furnace

This heating system melts brass, copper, iron, and steel. It manages various capabilities: 500kg, 750kg, 1000kg, and 1 lot. The 1-ton version equates to the 1000kg version. These furnaces make use of electricity. They are developed for heavy industrial use.

The heating system body is solid steel plate. The inside uses high-grade refractory blocks. This lining withstands severe heat. It lasts a very long time. The melting temperature level array is broad. It goes from 1200 ° C to 1800 ° C. Different steels need different heat degrees. Brass thaws lower than steel. The heating system changes for this.

Power needs differ by dimension. Larger heaters need even more power. Anticipate 380V three-phase power. Power levels vary from 100kW to over 300kW. Check the particular design. The heater consists of a turning system. It makes use of hydraulic or electrical power. Tilting pours the liquified steel safely. Crucibles hold the steel inside. Crucibles are replaceable. They are made for heats.

The heater utilizes graphite or silicon carbide aspects. These heat up quickly. They offer reliable melting. Temperature level control is digital. A PLC or microprocessor handles it. This guarantees exact heat. Operators set the desired temperature. The system keeps it. Overheat security is typical. Safety and security sensors stop damage.

The furnace structure is durable. It consists of a tough base framework. Electric cupboards house the controls. Cooling systems protect against getting too hot. Water or air cooling is used. Installation requires a strong structure. Operation needs experienced personnel. Routine upkeep is important. This maintains the heater running well. It guarantees lengthy service life. The heating system is developed for dependability. It handles demanding foundry job. Production environments depend on it.

(500kg 750kg 1000kg 1 Ton Brass Copper Iron Steel Melting Furnace Industrial Furnace Electric Furnace)

Applications of 500kg 750kg 1000kg 1 Ton Brass Copper Iron Steel Melting Furnace Industrial Furnace Electric Furnace

These furnaces thaw metal. They handle brass, copper, iron, steel. Abilities are 500kg, 750kg, 1000kg, 1 heap. Shops utilize them continuously. They make spreadings for machinery parts. They make automobile parts. They make plumbing fixtures. Metalworking shops rely upon them. They produce custom items. They carry out fixings. They do little production runs. Recycling operations need these heaters. They thaw scrap brass and copper. They melt scrap iron and steel. This transforms waste into functional product. Jewelers make use of smaller variations. Bigger workshops make use of these dimensions. They are ideal for mid-volume job.

Brass melting prevails. It makes valves and fittings. It makes ornamental equipment. It makes musical tools. Copper melting is important. It produces electric wiring. It creates bus bars. It generates warmth exchangers. Iron melting creates hefty parts. Assume engine blocks. Think maker bases. Think construction aspects. Steel melting is essential. It makes devices. It makes blades. It makes architectural assistances. Electric home heating is effective. It supplies specific temperature level control. This matters for alloy top quality. It reduces oxidation compared to fuel furnaces. This conserves steel. It enhances the final product.

Different abilities match various demands. A 500kg heating system fits smaller sized stores. It handles daily spreading tasks. It deals with specific recycling sets. The 750kg model uses a lot more volume. It supports expanding procedures. It permits longer runs. The 1000kg or 1 heap furnace fits severe production. It satisfies higher need. It refines larger scrap loads. All dimensions are industrial-grade. They are built tough. They run long hours. They endure intense warmth. Electric procedure is cleaner. It usually fulfills stricter workshop guidelines. It stays clear of fuel storage space problems. Upkeep is normally simpler. Operators learn swiftly. These furnaces are a useful remedy. They deliver molten metal dependably. They are an essential device for metal services.

Company Profile

PDDN Photoelectron Technology Co., Ltd. is one of the leading enterprises in power electronics technology and power products, which is fully involved in developing solar inverters, transformers, voltage regulators, distribution cabinets, thyristors, modules, diodes, heaters, and other electronic devices or semiconductors. We will be committed to providing users with high-quality, efficient products and considerate service.

It accepts payment via Credit Card, T/T, West Union, and Paypal. PDDN will ship the goods to customers overseas through FedEx, DHL, by sea, or by air. If you want high-quality 500kg 750kg 1000kg 1 Ton Brass Copper Iron Steel Melting Furnace Industrial Furnace Electric Furnace, please send us inquiries; we will be here to help you.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

Storage Conditions

1) Store in a dry environment at room temperature.

2) Avoid damp and high temperature.

3) Use immediately after opening the inner packing bag.

5 FAQs of 500kg 750kg 1000kg 1 Ton Brass Copper Iron Steel Melting Furnace Industrial Furnace Electric Furnace

What metals does this furnace melt?

It melts brass, copper, iron, and steel. These are common industrial metals. The furnace handles them all effectively. You choose the metal based on your project needs.

How much metal can it hold?

Capacity options are 500kg, 750kg, 1000kg, or 1 ton. Pick the size matching your production volume. It holds the molten metal securely during operation. Larger sizes mean more metal melted per batch.

What power does it need?

It runs on three-phase industrial electricity. Standard workshop power won’t work. You must have the correct high-voltage supply. Check your local power specs before buying.

How fast does it melt metal?

Melting time depends on the metal type and furnace size. Generally, it heats metal quickly. The induction heating method is very efficient. Expect faster melting than older furnace types.

Is it safe to operate?

Yes, it has strong safety features. These include automatic shut-off and temperature controls. Proper operator training is essential. Always follow the safety manual instructions. Wear protective gear near the furnace.

(500kg 750kg 1000kg 1 Ton Brass Copper Iron Steel Melting Furnace Industrial Furnace Electric Furnace)

REQUEST A QUOTE

RELATED PRODUCTS

200A 300V Thyristor Rectifier Use for Electrophoresis

Three Phase Thyristor Trigger Board Thyristor Voltage Regulation Rectifier Module Power Regulator Power Controller

50Kw-20Mw Electricity Generation Small Hydro Power Plant

Reactor Capacitor Thyristor Switched Capacitor Power Factor Capacitor Bank

WGZX DUAL SOLID STATE RELAY