Electronic Components Supplier | Transformers, Inductors, Inverters

PRODUCT PARAMETERS

Description

Overview of 6 Zone China Hot Runner Hot Runner PID Temperature Controller for Plastic Injection Mould

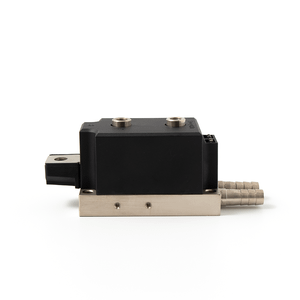

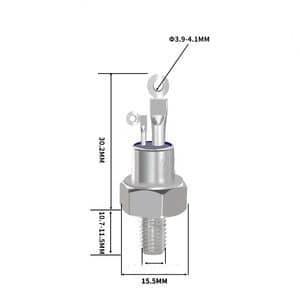

Thyristor is a solid-state semiconductor device composed of four layers of alternating P- and N-type materials. It functions as a bistable switch, conducting current only when triggered by a gate signal, and remains conducting until the voltage across it drops below a certain threshold. Thyristors are widely used for controlling high-power electrical circuits, offering efficient and reliable performance in various industrial and electronic applications.

Features of 6 Zone China Hot Runner Hot Runner PID Temperature Controller for Plastic Injection Mould

- High current and voltage handling capabilities

- Low on-state voltage drop, reducing power loss

- Fast switching speeds for precise control

- Latching behavior: once triggered, remains conducting without continuous gate signal

- Robust and durable design suitable for harsh environments

- Available in various types (e.g., SCR, TRIAC, GTO) for specific needs

(6 Zone China Hot Runner Hot Runner PID Temperature Controller for Plastic Injection Mould)

Specifications of 6 Zone China Hot Runner Hot Runner PID Temperature Controller for Plastic Injection Mould

This 6 Zone China warm jogger PID temperature level controller takes care of home heating inside plastic injection molds. It manages six different home heating areas separately. You set accurate temperatures for each zone. This makes sure constant warmth specifically where needed.

The controller utilizes sophisticated PID technology. PID continuously inspects the genuine temperature level. It compares this to your collection point. It after that makes tiny changes to the heater power. This maintains temperature levels unbelievably stable. Secure warmth prevents plastic problems like deterioration or bad flow. Your plastic melts uniformly.

A clear electronic screen reveals everything. You see the set temperature level for each area. You additionally see the real gauged temperature. Seeing both worths is essential. You know promptly if a zone is heating up properly. The display screen reveals power output portion as well. This suggests just how hard each heater is functioning.

The controller includes integrated alarms. It informs you if an area gets too warm. It likewise notifies you if a zone is too cool. Alarm systems alert you if a sensor fails. These cautions assist safeguard your mold and mildew and plastic. They avoid expensive damages.

Inputs make use of typical K-type thermocouples. Thermocouples gauge the temperature level in each zone. They send this information back to the controller. Results make use of reliable solid-state relays (SSRs). SSRs switch over the power to the heating systems on and off swiftly. This offers smooth, precise home heating control.

The unit operates standard power voltages. Usual alternatives are 110VAC or 220VAC. It connects conveniently to your warm jogger system. Installment is straightforward. Fuses protect the interior circuits. This adds safety.

Use this controller for specific warm jogger administration. It provides trusted temperature control zone by area. This leads to consistent, high-quality plastic parts. It manages the needs of injection molding manufacturing.

(6 Zone China Hot Runner Hot Runner PID Temperature Controller for Plastic Injection Mould)

Applications of 6 Zone China Hot Runner Hot Runner PID Temperature Controller for Plastic Injection Mould

This China-made 6 Area Hot Runner PID Temperature level Controller takes on typical plastic injection molding headaches. Ever before obtain flow lines, sink marks, or inconsistent components? Specific temperature control fixes that. This device handles six separate home heating zones separately. Each area obtains its very own PID formula constantly adjusting power. This maintains temperature levels incredibly constant, appropriate where you set them. Forget the discouraging temperature swings older controllers have. Constant warmth implies far better plastic flow inside the mold.

It stops product destruction. Overheating burns plastic, messing up parts. This PID controller quits that. It also conserves energy. The wise PID system makes use of just the power required, reducing prices. The screen is clear and easy. Operators see all six area temperature levels immediately. Changing setpoints is uncomplicated. Alerts caution you right away if any kind of area gets too hot or underheats. This conserves material and stays clear of ditching bitter pills.

The controller is constructed tough for the. It handles resonances, dust, and typical shop conditions well. Stable performance is key for lengthy manufacturing runs. You get constant component quality, hour after hour. This dependability implies much less downtime dealing with temperature problems. It works completely for complicated molds requiring different temperature levels in various areas. Believe multi-cavity mold and mildews for little parts like container caps or detailed parts like mobile phone instances. Exact control ensures every cavity loads completely.

Company Profile

PDDN Photoelectron Technology Co., Ltd. is one of the leading enterprises in power electronics technology and power products, which is fully involved in developing solar inverters, transformers, voltage regulators, distribution cabinets, thyristors, modules, diodes, heaters, and other electronic devices or semiconductors. We will be committed to providing users with high-quality, efficient products and considerate service.

It accepts payment via Credit Card, T/T, West Union, and Paypal. PDDN will ship the goods to customers overseas through FedEx, DHL, by sea, or by air. If you want high-quality 6 Zone China Hot Runner Hot Runner PID Temperature Controller for Plastic Injection Mould, please send us inquiries; we will be here to help you.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

Storage Conditions

1) Store in a dry environment at room temperature.

2) Avoid damp and high temperature.

3) Use immediately after opening the inner packing bag.

5 FAQs of 6 Zone China Hot Runner Hot Runner PID Temperature Controller for Plastic Injection Mould

What makes this temperature controller different?

It uses PID technology. This gives very exact temperature control. Your plastic flows evenly every time. You avoid material waste and bad parts. It works much better than basic controllers.

Will it work with my factory’s power?

Yes. The controller handles common voltages like 200-240V AC. It adjusts automatically. Check your machine’s specs to be safe. You won’t need extra transformers usually.

How does it warn me about problems?

Built-in alarms spot issues fast. It checks for overheating, sensor breaks, and power trouble. Lights flash and a buzzer sounds. You know immediately something needs fixing. This protects your molds.

Is this controller built to last?

Yes. It uses strong industrial parts. The design handles factory heat and vibration well. It runs reliably for long periods. You get a stable process with less downtime.

Is setting it up difficult?

No. The controls are straightforward. The display shows clear numbers. Changing temperatures is simple. Most operators learn it quickly. You spend less time training and more time producing.

(6 Zone China Hot Runner Hot Runner PID Temperature Controller for Plastic Injection Mould)

REQUEST A QUOTE

RELATED PRODUCTS

Foot Pedal Spot Welding Machine Thyristor Controller Resistor Welder Electrode Arm High Quality

Power Quality Device Advance Capacitor Controller Thyristor Switching Capacitor & Reactor Reactive Power Compensation Cabinet

High-Power DC Three-phase Rectifier Bridge Rectifier Module MDS60A100A200A500A12V/220V

Three Phase Power Control Unit Thyristor (SCR Power Controller) Ramp / Soak Controllers

Static SCR 50KVA Automatic Thyristor Voltage Stabilizer