Electronic Components Supplier | Transformers, Inductors, Inverters

PRODUCT PARAMETERS

Description

Overview of Billet Electric Induction Heating Furnace

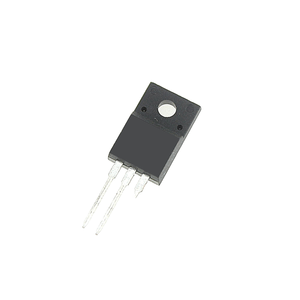

Thyristor is a solid-state semiconductor device composed of four layers of alternating P- and N-type materials. It functions as a bistable switch, conducting current only when triggered by a gate signal, and remains conducting until the voltage across it drops below a certain threshold. Thyristors are widely used for controlling high-power electrical circuits, offering efficient and reliable performance in various industrial and electronic applications.

Features of Billet Electric Induction Heating Furnace

- High current and voltage handling capabilities

- Low on-state voltage drop, reducing power loss

- Fast switching speeds for precise control

- Latching behavior: once triggered, remains conducting without continuous gate signal

- Robust and durable design suitable for harsh environments

- Available in various types (e.g., SCR, TRIAC, GTO) for specific needs

(Billet Electric Induction Heating Furnace)

Specifications of Billet Electric Induction Heating Furnace

This billet electrical induction heating furnace heats up metal billets quickly. It uses electro-magnetic power. This method is effective. It provides constant warm. The furnace matches creating and rolling procedures.

Power rankings vary. Units range from 100 kW to over 3000 kW. Power depends upon billet size. It likewise relies on production rate. Frequency options exist. Tool frequency prevails. Medium regularity works well for billets.

Heating speed is crucial. This heater warms quickly. Home heating prices reach 300 ° C per min. Faster heating saves time. It enhances performance. Temperature level control is specific. Operators established the target temperature. The system holds it properly. Normal max temperature levels hit 1250 ° C. This matches most steel forging.

Billet capability is flexible. Heating systems take care of diameters from 50mm to 300mm. Lengths differ as well. Criterion lengths are 1 meter to 6 meters. Personalized dimensions are feasible. Material kind issues. It benefits carbon steel, alloy steel, stainless-steel.

Automation is common. PLC controls manage whatever. Operators utilize a touchscreen. The system tracks temperature level. It keeps an eye on power usage. Security features are integrated. Water air conditioning protects coils. Overheat sensors prevent damage.

The heater body is durable. It makes use of hefty steel building. Insulation maintains warm inside. This saves energy. Copper coils generate the induction field. Coils require water air conditioning. The cooling system is included.

Feed systems relocate billets. Alternatives consist of roller tables or pushers. Release systems get rid of warm billets. These systems sync with the furnace cycle. The layout lessens warmth loss. Efficiency is high. Power aspect correction is usually built-in. This lowers electrical energy prices.

(Billet Electric Induction Heating Furnace)

Applications of Billet Electric Induction Heating Furnace

Billet electric induction heating furnaces warm steel billets quick. They do this successfully. Numerous industries utilize these heating systems. Creating plants rely upon them greatly. Billets need to be really hot before hammering or pressing right into forms. Induction heaters heat billets to the specific building temperature swiftly. This conserves time. It conserves energy too. The temperature level control is really specific. Consistent billet temperature level is vital for good creating outcomes.

Extrusion operations need these furnaces. Extrusion presses warm metal with a die to create lengthy shapes. Aluminum and copper billets typically get heated in this manner. Induction home heating brings the billet core and surface to the exact same temperature evenly. This avoids defects in the extruded product. The process is trusted for high-volume assembly line.

Moving mills make use of induction heaters for billets prior to rolling. Rolling reduces the billet’s density or changes its form. The billet needs to be heated evenly throughout. Induction home heating ensures this consistent warm. It stops surface area getting too hot or a cold facility. This causes far better high quality rolled items like bars or poles. Mill throughput increases because home heating is fast.

Special warm treatments often make use of induction heaters. They can heat up billets for specific processes requiring regulated problems. The ability to heat only the billet precisely is essential. Marginal warmth impacts the surrounding area. This secures other devices. Induction heating systems use adaptability. Operators can adjust heating patterns conveniently. Different billet dimensions and materials are manageable. Steel, light weight aluminum, copper, brass– all can be processed. The goal is constantly the same: get the billet warm, right, and prepared for the following action quick.

Company Profile

PDDN Photoelectron Technology Co., Ltd. is one of the leading enterprises in power electronics technology and power products, which is fully involved in developing solar inverters, transformers, voltage regulators, distribution cabinets, thyristors, modules, diodes, heaters, and other electronic devices or semiconductors. We will be committed to providing users with high-quality, efficient products and considerate service.

It accepts payment via Credit Card, T/T, West Union, and Paypal. PDDN will ship the goods to customers overseas through FedEx, DHL, by sea, or by air. If you want high-quality Billet Electric Induction Heating Furnace, please send us inquiries; we will be here to help you.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

Storage Conditions

1) Store in a dry environment at room temperature.

2) Avoid damp and high temperature.

3) Use immediately after opening the inner packing bag.

5 FAQs of Billet Electric Induction Heating Furnace

How does this billet induction furnace heat metal?

It uses electricity. Powerful coils create a magnetic field. This field makes the billet itself get hot inside. No flames touch the metal. The heat starts deep within the billet material.

Does it save energy compared to gas furnaces?

Yes, usually. It heats the billet directly. Less heat escapes into the air around it. This makes it more efficient. You use less power overall. Your energy bills decrease.

Can it control the billet temperature precisely?

Yes, it controls temperature very well. Sensors constantly check the billet’s heat. The system adjusts power instantly. This keeps the temperature exactly where you need it. Uniform heating happens every time.

How fast does it heat a billet?

It heats billets extremely fast. The process starts inside the metal. There’s no waiting for heat to travel inward from the surface. Heating times are much shorter than older furnace types. Production speeds increase.

Is it safe to operate?

Yes, safety is a major advantage. No open flames or hot combustion gases exist. The billet heating zone stays enclosed. Operators work away from extreme radiant heat. Automated systems reduce manual handling risks. Safety alarms and shut-offs are standard.

(Billet Electric Induction Heating Furnace)

REQUEST A QUOTE

RELATED PRODUCTS

High Efficiency Thyristor Power Regulator Wide Input Range Stabilizer Whole AC Current Three Phase

Three-phase Thyristor Switches Dynamic Thyristor Switches Capacitor Quick-throw Switches

Hot AC 220V-380V High Voltage Capacity Energy-saving Controller Stabilizer Thyristor SCR Power Regulator

Factory LV 690V Power Factor 0.98 Thyristor Switch Control TSC 200Kvar Capacitor Automatic Compensation Device

Induction Heating Furnace