Electronic Components Supplier | Transformers, Inductors, Inverters

PRODUCT PARAMETERS

Description

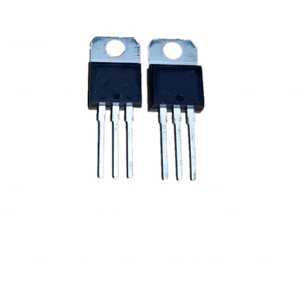

Overview of Diode module High power diode module rectifier power supply

Thyristor is a solid-state semiconductor device composed of four layers of alternating P- and N-type materials. It functions as a bistable switch, conducting current only when triggered by a gate signal, and remains conducting until the voltage across it drops below a certain threshold. Thyristors are widely used for controlling high-power electrical circuits, offering efficient and reliable performance in various industrial and electronic applications.

Features of Diode module High power diode module rectifier power supply

- High current and voltage handling capabilities

- Low on-state voltage drop, reducing power loss

- Fast switching speeds for precise control

- Latching behavior: once triggered, remains conducting without continuous gate signal

- Robust and durable design suitable for harsh environments

- Available in various types (e.g., SCR, TRIAC, GTO) for specific needs

(Diode module High power diode module rectifier power supply)

Specifications of Diode module High power diode module rectifier power supply

This high power diode module rectifier converts AC power to DC power reliably. It handles large currents and high voltages needed for tough industrial jobs. Think electroplating, anodizing, welding machines, or big battery chargers. These modules are built tough for constant use.

The core uses high-grade silicon diodes. These are mounted on strong, insulated copper or aluminum bases. This base pulls heat away efficiently. Good heat management is vital. It stops the module from overheating and failing early. The module connects directly to a heatsink. This setup keeps temperatures safe during heavy loads.

Voltage ratings are high. Common modules handle 1600V, 2000V, or even more. This high blocking voltage prevents damage from power surges. Current ratings are also substantial. Modules manage 100A, 200A, 500A, or higher continuous DC output. Peak currents can be much larger briefly. Always check the specific module’s datasheet for exact numbers.

The insulation between the diode and the base is critical. It withstands high voltages. This prevents dangerous shorts. Low thermal resistance is another key feature. It means heat moves quickly from the diodes into the heatsink. This keeps the diodes cooler. Cooler diodes last longer and work better.

These modules are simple to install. They bolt directly onto the heatsink. No complex mounting hardware is usually needed. Electrical connections are straightforward screw terminals or bus bars. This design saves time during setup and maintenance. Reliability is a major advantage. Solid construction means less downtime and fewer repairs.

Performance is consistent across a wide temperature range. Typical operating temperatures go from -40°C to +150°C junction temperature. Good efficiency is standard. Power loss is kept low, mainly as heat. Effective cooling manages this heat well. The robust package protects the internal components. It resists vibration and harsh factory conditions.

(Diode module High power diode module rectifier power supply)

Applications of Diode module High power diode module rectifier power supply

High power diode modules are key parts in modern rectifier power supplies. They change alternating current (AC) into direct current (DC). This conversion is vital for many industrial processes needing steady, high-power DC electricity. These modules pack many strong diodes together. This design handles huge currents and voltages efficiently.

Rectifier power supplies using these modules are built tough. They manage large electrical loads reliably. Their strong construction means they work well in demanding factory settings. Heat is a big issue with high power. So, these modules usually have good cooling systems. This might be heatsinks, fans, or liquid cooling. Keeping cool prevents damage and extends the equipment’s life.

These power supplies are used widely. Electroplating factories need them for coating metal parts evenly. The stable DC current ensures a smooth, high-quality finish. Welding machines rely on them too. They provide the steady, powerful current needed for strong, consistent welds on thick materials. Battery charging stations use them, especially for big industrial batteries. They convert grid power to the right DC voltage quickly and safely.

Anodizing aluminum requires precise DC power. These rectifiers deliver the exact control needed for this process. They are also common in metal refining. Processes like electrolysis use them to extract or purify metals from solutions using electricity. Motor speed control in large machines often uses DC drives powered by these rectifiers. They provide the variable DC power needed. Other uses include powering big magnets, laboratory test equipment, and some renewable energy systems needing DC conversion.

Their main advantage is handling very high power levels reliably. They offer good efficiency, meaning less wasted energy. This saves money on electricity. Their robust design reduces breakdowns and maintenance needs. This keeps production lines running smoothly.

Company Profile

PDDN Photoelectron Technology Co., Ltd. is one of the leading enterprises in power electronics technology and power products, which is fully involved in developing solar inverters, transformers, voltage regulators, distribution cabinets, thyristors, modules, diodes, heaters, and other electronic devices or semiconductors. We will be committed to providing users with high-quality, efficient products and considerate service.

It accepts payment via Credit Card, T/T, West Union, and Paypal. PDDN will ship the goods to customers overseas through FedEx, DHL, by sea, or by air. If you want high-quality Diode module High power diode module rectifier power supply, please send us inquiries; we will be here to help you.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

Storage Conditions

1) Store in a dry environment at room temperature.

2) Avoid damp and high temperature.

3) Use immediately after opening the inner packing bag.

5 FAQs of Diode module High power diode module rectifier power supply

What is a high power diode module?

It changes AC power to DC power. It handles large currents. It uses multiple diodes in one block. This makes it strong. It works for heavy-duty jobs.

Why do diode modules need cooling?

They get hot during use. Heat can damage them. Cooling keeps temperatures safe. Methods include fans, heat sinks, or liquid cooling. Proper cooling means longer life and steady work.

Where are these modules typically used?

Factories use them a lot. They power big machines like welders or electroplating lines. They are in power supplies for large equipment. Battery chargers use them. Any place needing lots of DC power might need one.

How reliable are high power diode modules?

They are built tough. Good ones last a long time. They handle high currents and voltages. Proper installation matters. Following the specs matters. Good cooling matters. Do these things, reliability is high.

How do I pick the right diode module?

Look at the voltage it needs. Look at the current it must handle. Check the cooling method required. See the physical size and connections. Match these to your power supply’s job. Getting the right fit prevents problems.

(Diode module High power diode module rectifier power supply)

REQUEST A QUOTE

RELATED PRODUCTS

Permanent Magnet Generator AC Hydro Power Generators Sets 200kw

SCR System Disc Thyristor Phase Control Modules for DC and AC Motor Inverter Triac Thyristor Application

high power Triac thyristor

300Kvar TSC Reactive Compensation Power Factor Panel 380v Thyristor Switched Capacitor

Metal Table Lamp Touch Switch Module AC110V-220V LED Incandescent Bulb Thyristor Dimming ON-OFF High Tension Touch Switch