Electronic Components Supplier | Transformers, Inductors, Inverters

PRODUCT PARAMETERS

Description

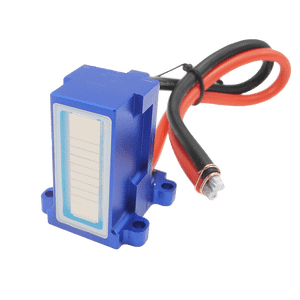

Overview of Double Pulse Encoder Spot Welding Machine Time Current Controller Control Panel Board Adjustable Digital Display

Thyristor is a solid-state semiconductor device composed of four layers of alternating P- and N-type materials. It functions as a bistable switch, conducting current only when triggered by a gate signal, and remains conducting until the voltage across it drops below a certain threshold. Thyristors are widely used for controlling high-power electrical circuits, offering efficient and reliable performance in various industrial and electronic applications.

Features of Double Pulse Encoder Spot Welding Machine Time Current Controller Control Panel Board Adjustable Digital Display

- High current and voltage handling capabilities

- Low on-state voltage drop, reducing power loss

- Fast switching speeds for precise control

- Latching behavior: once triggered, remains conducting without continuous gate signal

- Robust and durable design suitable for harsh environments

- Available in various types (e.g., SCR, TRIAC, GTO) for specific needs

(Double Pulse Encoder Spot Welding Machine Time Current Controller Control Panel Board Adjustable Digital Display)

Specifications of Double Pulse Encoder Spot Welding Machine Time Current Controller Control Panel Board Adjustable Digital Display

This control board features an adjustable digital screen. You see key welding specifications clearly. This consists of weld time, existing, and the pause time between pulses. The display screen is bright. It is simple to review in various store illumination conditions.

The core innovation is the dual pulse encoder. This provides exact control over the welding energy. The first pulse creates the first weld nugget. The 2nd pulse applies controlled warm. This fine-tunes the weld quality. It stops usual issues like spatter or weak joints.

You established the specific timing for each and every pulse. You set the exact current level for each and every pulse. The digital encoder ensures these settings are precise. It repeats the specific same setups every weld cycle. Consistency is crucial for strong, trusted welds.

Programming the controller is straightforward. Use the encoder knob to choose the criterion you intend to alter. Transform the handle to raise or decrease the value. The display screen shows the brand-new setup right away. The settings are saved instantly. No complex food selections exist.

The board takes care of the whole welding sequence. It sets off the weld timer. It controls the welding existing outcome. It regulates the pause in between both pulses. It indicates completion of the cycle. This automation simplifies the operator’s task.

Changes are quick. You fine-tune the procedure for different materials. You make improvements for different densities. The electronic responses assists optimize weld quality. It assists lessen power use. Manufacturing effectiveness improves. Denies reduction.

(Double Pulse Encoder Spot Welding Machine Time Current Controller Control Panel Board Adjustable Digital Display)

Applications of Double Pulse Encoder Spot Welding Machine Time Current Controller Control Panel Board Adjustable Digital Display

This Double Pulse Encoder Area Welding Equipment Controller Panel is essential gear for exact metal signing up with. It regulates the critical place welding procedure with accuracy. The double pulse technology delivers two quick bursts of energy. This technique considerably improves weld high quality. It stops overheating slim materials. It makes sure solid joints on complicated mixes like aluminum or layered steel. Car manufacturers rely upon this for constant body panel welds. Electronics factories utilize it for fragile battery pack links.

The integrated encoder tracks the welding head placement flawlessly. This guarantees every weld lands specifically where configured. Misplaced welds lose time and product. This encoder quits that problem. You get trusted positioning each time. The digital screen reveals whatever clearly. You see the welding current and timing settings live. Keeping an eye on these specifications is straightforward. You capture issues before they spoil parts. The huge screen prevents confusion.

Readjusting the settings is uncomplicated. The control board allows you alter welding time and present quickly. Different tasks require different power degrees. This panel manages those adjustments rapidly. Discovering the very best settings for a new material is quicker. Manufacturing downtime diminishes. Operators discover the controls quickly. Training time decreases. The digital precision indicates repeatable results. Every weld matches the last one. Consistency is key in high-volume manufacturing. This controller supplies that.

The Moment Existing Controller handles the power flow with accuracy. It times the electrical pulses perfectly. Managing the pulse duration and interval is essential. It impacts weld infiltration and strength straight. Excessive warmth buckles the metal. Inadequate creates weak spots. This controller locates the pleasant place. You achieve solid, tidy welds without harming the product. Steel fabricators worth this control for complicated settings up. Aerospace vendors demand this level of accuracy.

Company Profile

PDDN Photoelectron Technology Co., Ltd. is one of the leading enterprises in power electronics technology and power products, which is fully involved in developing solar inverters, transformers, voltage regulators, distribution cabinets, thyristors, modules, diodes, heaters, and other electronic devices or semiconductors. We will be committed to providing users with high-quality, efficient products and considerate service.

It accepts payment via Credit Card, T/T, West Union, and Paypal. PDDN will ship the goods to customers overseas through FedEx, DHL, by sea, or by air. If you want high-quality Double Pulse Encoder Spot Welding Machine Time Current Controller Control Panel Board Adjustable Digital Display, please send us inquiries; we will be here to help you.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

Storage Conditions

1) Store in a dry environment at room temperature.

2) Avoid damp and high temperature.

3) Use immediately after opening the inner packing bag.

5 FAQs of Double Pulse Encoder Spot Welding Machine Time Current Controller Control Panel Board Adjustable Digital Display

What is this controller for?

This board controls timing and current in double pulse encoder spot welding. It ensures precise welds. Operators adjust settings easily. It works with different spot welding machines. Setup is straightforward.

What does the digital display show?

The LCD screen shows welding parameters clearly. You see the welding time. You see the welding current level. It shows pulse counts too. Settings changes update immediately on screen. This helps monitor the process.

How do I adjust the welding pulses?

Use the buttons on the panel. Press the pulse time button. Then increase or decrease the value shown. Press the current button next. Adjust the current level the same way. The machine saves your settings automatically.

Do I need to calibrate this controller?

Calibrate the machine after installing the board. Follow the machine maker’s guide. Calibration checks the timing accuracy. It checks the current output matches the display. Do this for consistent weld quality. Recalibrate if you notice problems.

What if the display shows an error code?

Error codes mean a problem exists. Common codes relate to overcurrent or timing faults. Check the manual for the specific code meaning. Inspect the welding cables and connections first. Verify the power supply is stable. Contact technical support if the error persists.

(Double Pulse Encoder Spot Welding Machine Time Current Controller Control Panel Board Adjustable Digital Display)

REQUEST A QUOTE

RELATED PRODUCTS

High Current Capacity SCR MTC30-160 Power Module Cheap Thyristor ICs

Single-phase dual circuit Thyristor phase-shifting trigger for module

Original Photocoupler Integrated Circuits Chip Component Transistors Thyristor

TRIACS BTA16 Serial Thyristor 600V 800V 16A For ON/OFF Function Applications

10,000W High-power Thyristor Electronic Voltage Regulator, Motor Fan,speed Regulator, Temperature Controller, 220V