Electronic Components Supplier | Transformers, Inductors, Inverters

PRODUCT PARAMETERS

Description

Overview of high power Triac thyristor

Thyristor is a solid-state semiconductor device composed of four layers of alternating P- and N-type materials. It functions as a bistable switch, conducting current only when triggered by a gate signal, and remains conducting until the voltage across it drops below a certain threshold. Thyristors are widely used for controlling high-power electrical circuits, offering efficient and reliable performance in various industrial and electronic applications.

Features of high power Triac thyristor

- High current and voltage handling capabilities

- Low on-state voltage drop, reducing power loss

- Fast switching speeds for precise control

- Latching behavior: once triggered, remains conducting without continuous gate signal

- Robust and durable design suitable for harsh environments

- Available in various types (e.g., SCR, TRIAC, GTO) for specific needs

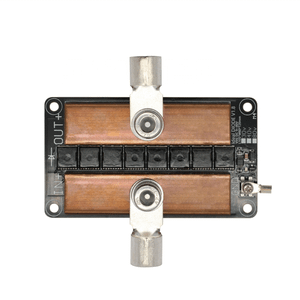

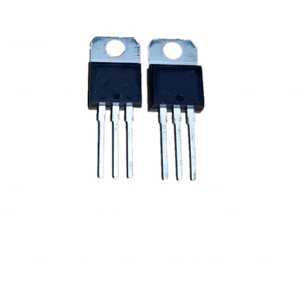

(high power Triac thyristor)

Specifications of high power Triac thyristor

High power Triac thyristors handle big AC loads. They switch AC power both ways. This makes them vital for controlling motors, heaters, and lights. Knowing their specs is key for reliable use.

Voltage ratings matter most. Look at the peak repetitive off-state voltage (VDRM). This tells you the maximum voltage the Triac blocks safely. Also check the RMS on-state voltage rating. This relates to the power it carries when conducting. Never exceed these voltage limits.

Current handling is critical. The RMS on-state current (IT(RMS)) shows the continuous current the Triac manages. The non-repetitive surge current rating (ITSM) is crucial too. It shows the maximum short burst current it survives. This protects against unexpected spikes.

Gate triggering controls the Triac. The gate trigger voltage (VGT) and current (IGT) must be met. Your control circuit must provide enough power to turn it on reliably. The holding current (IH) is the minimum current needed to keep it conducting after triggering. Check this for low-load situations.

Heat management is essential. High power means significant heat generation. The junction-to-case thermal resistance (RthJC) indicates how well heat moves from the silicon to the case. A lower number is better. You need a good heat sink. Mounting torque and thermal paste are vital for heat transfer. The maximum junction temperature (Tj) is the absolute limit. Staying well below this prevents failure.

Other specs include the critical rate of rise of off-state voltage (dv/dt). A high dv/dt rating prevents unwanted turn-on from voltage spikes. The commutation capability (di/dt) rating shows how fast the current can change direction when turning off. This is important for inductive loads like motors. Leakage currents in the off-state (IDRM) should be low for efficiency. Switching times define how fast it turns on and off. Faster switching reduces power loss but needs careful circuit design. Isolation voltage between the case and the live parts is vital for safety. High power Triacs suit demanding jobs like industrial motor drives and large lighting systems.

(high power Triac thyristor)

Applications of high power Triac thyristor

High power Triac thyristors manage alternating current flow effectively. They switch large electrical loads on and off. These devices control AC power. They handle heavy currents. That makes them perfect for demanding jobs.

Industrial heating systems rely on them. Think big ovens and furnaces. Triacs precisely adjust the heat inside. They manage the power going to heating elements. This control saves energy. It also keeps temperatures stable. Lighting control for big areas uses them too. They dim stadium lights smoothly. They switch streetlights reliably. This happens every day for years.

Motor speed control is another key area. Washing machines need variable spin speeds. Triacs make this possible. They regulate the power to the motor. Power tools like drills use them. You get variable speed control. This improves tool performance and safety.

Appliances everywhere depend on Triac reliability. Your electric stove uses them. So does your air conditioner. They switch the heating and cooling elements. They handle the high startup currents. This happens millions of times reliably. Power tools benefit significantly. They provide robust switching for motors. This ensures long life under tough conditions.

Industrial machinery uses them for motor drives. They control conveyor belt speeds. They manage pump flows. This is critical for factory automation. Phase control is their main method. They adjust the timing of power flow. This changes the effective voltage. It controls the power delivered. This method is simple and cost-effective. It works for many high-power AC loads.

Company Profile

PDDN Photoelectron Technology Co., Ltd. is one of the leading enterprises in power electronics technology and power products, which is fully involved in developing solar inverters, transformers, voltage regulators, distribution cabinets, thyristors, modules, diodes, heaters, and other electronic devices or semiconductors. We will be committed to providing users with high-quality, efficient products and considerate service.

It accepts payment via Credit Card, T/T, West Union, and Paypal. PDDN will ship the goods to customers overseas through FedEx, DHL, by sea, or by air. If you want high-quality high power Triac thyristor, please send us inquiries; we will be here to help you.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

Storage Conditions

1) Store in a dry environment at room temperature.

2) Avoid damp and high temperature.

3) Use immediately after opening the inner packing bag.

5 FAQs of high power Triac thyristor

What is a high power Triac?

It’s a solid-state electronic switch. It controls large amounts of AC electrical power. Think industrial heaters, big motors, or lighting systems. It turns on and off rapidly using a small control signal.

How much current and voltage can it handle?

These Triacs are built tough. They manage currents from 25 amps up to hundreds of amps. Voltage ratings go from 600 volts to over 1600 volts. Always check the specific part’s datasheet for exact numbers. Match it to your application’s needs.

Why is heat management critical?

Triacs generate significant heat during operation. Too much heat destroys the component. You must use a suitable heatsink. Proper mounting with thermal paste is essential. Good airflow helps. Never exceed the maximum junction temperature, usually 125°C.

How does the triggering work?

A small voltage on the gate terminal turns the Triac on. It stays on until the AC current drops to zero. Different trigger methods exist: simple resistor, resistor-capacitor (RC), or specialized driver circuits. The right method ensures reliable turn-on and reduces electrical noise.

What affects its lifespan and reliability?

Key factors are operating temperature, voltage spikes, and current surges. Running too hot shortens life dramatically. Voltage spikes from inductive loads (like motors) can cause failure. Use protection circuits like snubbers. Ensure the Triac stays within its rated limits. Proper installation prevents most problems.

(high power Triac thyristor)

REQUEST A QUOTE

RELATED PRODUCTS

High quality standard electronic components asymmetrical thyristor module thyristor control thyristor

1 Ton Capacity Iron Steel Small Induction Melting Furnace for Casting

Original SMD NPN Transistor High Performance Electronics

Diode module High power diode module rectifier power supply

electronics component transistors mosfet IGBT MODULE IGBT POWER MODULE Thyristor SCR Diodes