Electronic Components Supplier | Transformers, Inductors, Inverters

PRODUCT PARAMETERS

Description

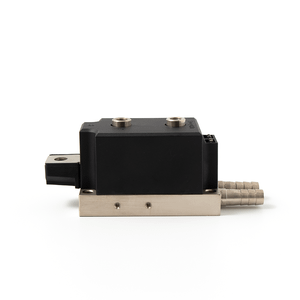

Overview of High Quality Silicon Controlled Rectifier (SCR) Thyristor Module for Resistance Welders Understanding the Working Principle

Thyristor is a solid-state semiconductor device composed of four layers of alternating P- and N-type materials. It functions as a bistable switch, conducting current only when triggered by a gate signal, and remains conducting until the voltage across it drops below a certain threshold. Thyristors are widely used for controlling high-power electrical circuits, offering efficient and reliable performance in various industrial and electronic applications.

Features of High Quality Silicon Controlled Rectifier (SCR) Thyristor Module for Resistance Welders Understanding the Working Principle

- High current and voltage handling capabilities

- Low on-state voltage drop, reducing power loss

- Fast switching speeds for precise control

- Latching behavior: once triggered, remains conducting without continuous gate signal

- Robust and durable design suitable for harsh environments

- Available in various types (e.g., SCR, TRIAC, GTO) for specific needs

(High Quality Silicon Controlled Rectifier (SCR) Thyristor Module for Resistance Welders Understanding the Working Principle)

Specifications of High Quality Silicon Controlled Rectifier (SCR) Thyristor Module for Resistance Welders Understanding the Working Principle

Resistance welders require dependable power control. Premium quality SCR thyristor components make this take place. They handle the huge currents required for strong, regular welds. Recognizing their requirements and how they function is key.

These modules are developed difficult. They take care of extremely high voltages, typically over 1000 volts. They handle massive currents, frequently reaching 1000 amps or more. This high existing capacity is essential for welding. Thermal efficiency is vital. Great modules efficiently dissipate warmth. They protect against harmful overheating inside the welder. Seek a high surge existing rating. This protects against abrupt, quick power spikes typical in welding. Sturdy construction is vital. It makes sure the component makes it through continuous vibration and electrical stress and anxiety.

The SCR component imitates a high-power button. It manages electrical energy flow to the welding transformer. An SCR has three parts: anode, cathode, and gateway. Usually, no existing flows in between anode and cathode. A little signal sent to the gate activates the SCR. When activated, the SCR switches on totally. It lets existing flow freely from anode to cathode. The SCR stays on till the current declines almost to no. This occurs instantly every half-cycle with air conditioner power. The gate signal only needs to begin the conduction.

Exact timing is the SCR’s main task. The control circuit sends an entrance signal at a particular minute within the a/c cycle. This timing straight regulates the power supplied to the weld. Terminating the SCR early in the cycle sends out even more power. Terminating it later on sends less power. This is called phase-angle control. Some systems make use of zero-crossing control for various needs. The SCR component performs this timing command precisely. This allows you exactly time the weld energy. Exact timing guarantees regular weld top quality every single time. It secures the work surfaces and the welding tools itself.

(High Quality Silicon Controlled Rectifier (SCR) Thyristor Module for Resistance Welders Understanding the Working Principle)

Applications of High Quality Silicon Controlled Rectifier (SCR) Thyristor Module for Resistance Welders Understanding the Working Principle

Resistance welders require precise heat control. SCR thyristor components provide this essential control. Think of an SCR as an effective digital switch. It handles the substantial electrical current moving to the welding electrodes. Controlling this current straight controls the warm produced at the weld factor.

An SCR module commonly includes 2 SCRs. They connect back-to-back. This configuration manages alternating existing (AC) power typical in manufacturing facilities. Each SCR regulates the power circulation during one fifty percent of the AC cycle. One SCR handles the favorable half. The other SCR handles the negative fifty percent. This enables full control over the entire air conditioner waveform.

The control system sends out a quick signal to the SCR component. This signal is the gate pulse. It informs the SCR precisely when to begin conducting electricity. As soon as triggered by the gate pulse, the SCR activates. It stays on for the remainder of that half-cycle. The SCR immediately switches off when the a/c current normally goes across absolutely no. This occurs every half-cycle. The SCR requires a new gate pulse to activate once again next cycle.

This accurate triggering is the key. The welder’s controller determines the precise timing. It sends eviction pulse at the precise minute needed. Starting transmission previously in the AC cycle sends out more power to the weld. Starting conduction later on sends out much less power. This is called phase-angle control. It gives very great modification of the welding heat.

Excellent quality SCR modules are essential for reliable welding. They handle high currents and voltages dependably. They switch on and off countless times regularly. Great modules guarantee constant weld quality. They stop weak welds or harming the components. They last a very long time even in difficult manufacturing facility problems. This conserves money on replacements and downtime.

Company Profile

PDDN Photoelectron Technology Co., Ltd. is one of the leading enterprises in power electronics technology and power products, which is fully involved in developing solar inverters, transformers, voltage regulators, distribution cabinets, thyristors, modules, diodes, heaters, and other electronic devices or semiconductors. We will be committed to providing users with high-quality, efficient products and considerate service.

It accepts payment via Credit Card, T/T, West Union, and Paypal. PDDN will ship the goods to customers overseas through FedEx, DHL, by sea, or by air. If you want high-quality High Quality Silicon Controlled Rectifier (SCR) Thyristor Module for Resistance Welders Understanding the Working Principle, please send us inquiries; we will be here to help you.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

Storage Conditions

1) Store in a dry environment at room temperature.

2) Avoid damp and high temperature.

3) Use immediately after opening the inner packing bag.

5 FAQs of High Quality Silicon Controlled Rectifier (SCR) Thyristor Module for Resistance Welders Understanding the Working Principle

SCR modules control welding current in resistance welders. They are vital for precise heat control. Think of them as high-power switches. They manage the huge electrical currents needed for welding. Without them, consistent welds are impossible.

What exactly do SCR modules do? They switch the welding current on and off. This happens extremely fast. They connect the power source to the welding transformer. The transformer then steps up the current for the weld. Precise timing is crucial for good welds.

How do SCRs control current flow? SCRs are special solid-state switches. They need a small trigger signal to turn on. Once on, they conduct full current until it drops nearly to zero. This natural turn-off fits the AC power used. They cycle on and off many times per second.

Why use SCRs instead of other switches? SCRs handle very high currents and voltages. They are reliable under tough industrial conditions. They switch incredibly fast. This speed allows precise control over heat input. Mechanical switches are too slow and wear out quickly.

How does the trigger signal work? The welder’s control sends a small electrical pulse. This pulse goes to the SCR’s gate terminal. It tells the exact moment to start conducting current. The pulse timing determines the weld heat. Different materials need different timing.

What happens during conduction? When triggered, the SCR lets current flow freely. Current passes from the anode to the cathode terminals. It flows only during the positive half-cycle of AC power. The SCR stops automatically when current naturally crosses zero. This repeats every cycle.

(High Quality Silicon Controlled Rectifier (SCR) Thyristor Module for Resistance Welders Understanding the Working Principle)

REQUEST A QUOTE

RELATED PRODUCTS

PSCR-3W Three-phase Thyristor Trigger Board Voltage Regulation Rectifier Module Power Regulator Dynamometer Power Controller

thyristor power controller scr power thyristor discrete thyristor

Disc Type Fast Switching Thyristor/Fast SCR/Fast Thyristor

High-Power DC Three-phase Rectifier Bridge Rectifier Module MDS60A100A200A500A12V/220V