Electronic Components Supplier | Transformers, Inductors, Inverters

PRODUCT PARAMETERS

Description

Overview of High Quality Thyristor Automatic Submerged Arc Welding Machine Easy Operation Thyristor Welder

Thyristor is a solid-state semiconductor device composed of four layers of alternating P- and N-type materials. It functions as a bistable switch, conducting current only when triggered by a gate signal, and remains conducting until the voltage across it drops below a certain threshold. Thyristors are widely used for controlling high-power electrical circuits, offering efficient and reliable performance in various industrial and electronic applications.

Features of High Quality Thyristor Automatic Submerged Arc Welding Machine Easy Operation Thyristor Welder

- High current and voltage handling capabilities

- Low on-state voltage drop, reducing power loss

- Fast switching speeds for precise control

- Latching behavior: once triggered, remains conducting without continuous gate signal

- Robust and durable design suitable for harsh environments

- Available in various types (e.g., SCR, TRIAC, GTO) for specific needs

(High Quality Thyristor Automatic Submerged Arc Welding Machine Easy Operation Thyristor Welder)

Specifications of High Quality Thyristor Automatic Submerged Arc Welding Machine Easy Operation Thyristor Welder

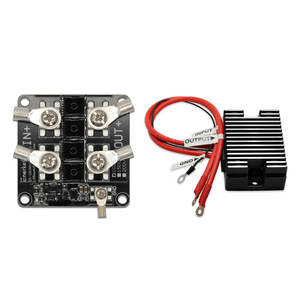

This thyristor automated immersed arc welding device provides leading performance. It makes use of dependable thyristor control modern technology. This provides specific power regulation. You obtain steady welding arcs constantly. The device deals with thick materials conveniently. It works well for long weld joints. Operation is simple for everybody. Employees learn it fast.

The maker provides vast welding current adjustment. You set the existing exactly where needed. Voltage control is additionally extremely accurate. This ensures deep penetration every time. Weld bead appearance remains uniform. The equipment includes automated cord feeding. Feed rate changes smoothly. This matches your welding rate perfectly.

Control panels are simple. Buttons and dials are clearly marked. Setups are very easy to see. Transforming parameters takes little effort. The system monitors itself constantly. It safeguards against overloads automatically. Safety and security attributes are built-in. This avoids damage to the equipment. Operators stay risk-free as well.

You link the device quickly. Configuration entails marginal actions. Routine checks are easy. Upkeep needs are reduced. This conserves workshop time. Downtime is minimized considerably. The layout is durable. It deals with challenging workshop conditions. Dependability is high. Manufacturing schedules remain on track. You achieve high quality welds reliably. This machine increases welding efficiency. It cuts manufacturing prices properly.

(High Quality Thyristor Automatic Submerged Arc Welding Machine Easy Operation Thyristor Welder)

Applications of High Quality Thyristor Automatic Submerged Arc Welding Machine Easy Operation Thyristor Welder

This Thyristor Automatic Submerged Arc Welding Machine manages laborious easily. It bonds thick steel plates fast. It gives solid, clean welds every time. You see it dealing with huge jobs. It builds huge stress vessels for manufacturing facilities. These hold fluids or gases safely. The equipment welds the lengthy seams perfectly. It makes storage tanks for oil or chemicals. These containers need leak-proof joints. This welder does that work well.

Shipyards depend on this tools. It signs up with hefty hull sections for ships. It welds decks and bulkheads as well. The equipment works consistently on long terms. Structural steel producers use it daily. It assembles beam of lights and columns for buildings and bridges. The welds have to hold significant weights. This device provides that strength.

Pipe building requires trustworthy welding. This thyristor welder joins huge pipes underground or above. It guarantees the pipe remains secured for years. Hefty machinery makers require it. It bonds structures and booms for excavators and cranes. These components encounter constant stress. Excellent welds prevent breaks and downtime.

The thyristor control is vital. It provides smooth, secure welding power. This indicates fewer flaws like porosity or fractures. Operators discover it straightforward to make use of. They established the voltage, present, and cord feed rate quickly. The maker maintains these settings steady. Operators do not require to readjust frequently. This saves time and lowers errors. Educating brand-new operators is quicker. The controls are straightforward. The equipment runs dependably change after change. It handles requiring manufacturing timetables. Construction stores obtain even more job done faster. The premium outcomes suggest less rework. Projects finish on schedule and within budget plan.

Company Profile

PDDN Photoelectron Technology Co., Ltd. is one of the leading enterprises in power electronics technology and power products, which is fully involved in developing solar inverters, transformers, voltage regulators, distribution cabinets, thyristors, modules, diodes, heaters, and other electronic devices or semiconductors. We will be committed to providing users with high-quality, efficient products and considerate service.

It accepts payment via Credit Card, T/T, West Union, and Paypal. PDDN will ship the goods to customers overseas through FedEx, DHL, by sea, or by air. If you want high-quality High Quality Thyristor Automatic Submerged Arc Welding Machine Easy Operation Thyristor Welder, please send us inquiries; we will be here to help you.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

Storage Conditions

1) Store in a dry environment at room temperature.

2) Avoid damp and high temperature.

3) Use immediately after opening the inner packing bag.

5 FAQs of High Quality Thyristor Automatic Submerged Arc Welding Machine Easy Operation Thyristor Welder

High Quality Thyristor Automatic Submerged Arc Welding Machine: 5 Key Questions Answered

Is this welding machine hard to set up?

No, it’s designed for easy operation. The controls are simple. You can understand them quickly. The thyristor technology adjusts power smoothly. This makes starting easier. Setting welding parameters is straightforward. New operators learn fast.

What maintenance does this thyristor welder need?

Regular checks keep it reliable. Inspect cables and connections often. Clean dust from the machine interior periodically. Check the cooling system works properly. The thyristor components are durable. They need minimal special care. Follow the basic schedule in the manual.

Can it weld different types of metal?

Yes, it handles many common metals. It works well on carbon steel. It works well on low-alloy steel. Stainless steel is also suitable. The stable arc control is key. It ensures consistent quality across materials. Adjust the current and voltage settings for each metal type.

Will it work on unstable power sources?

The thyristor design helps here. It compensates for minor power fluctuations. Voltage changes affect the weld less. This gives steadier performance. Very poor power might still cause issues. A stable input is always best.

Does it have safety features?

Yes, operator safety is important. It includes overload protection. This stops the machine if current gets too high. Thermal protection prevents overheating. Proper grounding is essential. Always wear correct welding safety gear.

(High Quality Thyristor Automatic Submerged Arc Welding Machine Easy Operation Thyristor Welder)

REQUEST A QUOTE

RELATED PRODUCTS

Dynamic Regulators Composed of Thyristors and Electronic Components Applied in Rapid Switching of Shunt Capacitors

Power Thyristor for Phase Control Triac Type

200A 300V Thyristor Controlled Rectifier for Anodic Electrophoretic Coating

thyristor power controller scr power thyristor discrete thyristor

fast turn-off thyristors kk500A kk600A kk700A kk800A kk900A kk1000A kk1200A kk1500A kk1800A kk2000A kk2500A kk3000A kk4000A