Electronic Components Supplier | Transformers, Inductors, Inverters

PRODUCT PARAMETERS

Description

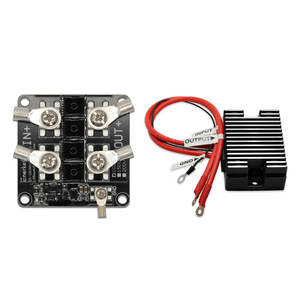

Overview of Hot ing Electrical Iron Smelting Oven Thyristor Induction Melting Furnace Stainless Steel Smelter

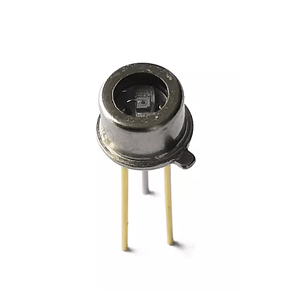

Thyristor is a solid-state semiconductor device composed of four layers of alternating P- and N-type materials. It functions as a bistable switch, conducting current only when triggered by a gate signal, and remains conducting until the voltage across it drops below a certain threshold. Thyristors are widely used for controlling high-power electrical circuits, offering efficient and reliable performance in various industrial and electronic applications.

Features of Hot ing Electrical Iron Smelting Oven Thyristor Induction Melting Furnace Stainless Steel Smelter

- High current and voltage handling capabilities

- Low on-state voltage drop, reducing power loss

- Fast switching speeds for precise control

- Latching behavior: once triggered, remains conducting without continuous gate signal

- Robust and durable design suitable for harsh environments

- Available in various types (e.g., SCR, TRIAC, GTO) for specific needs

(Hot ing Electrical Iron Smelting Oven Thyristor Induction Melting Furnace Stainless Steel Smelter)

Specifications of Hot ing Electrical Iron Smelting Oven Thyristor Induction Melting Furnace Stainless Steel Smelter

This electric induction furnace melts metal fast. It handles stainless steel, iron, and similar alloys. The core is a powerful induction coil. This coil creates a strong magnetic field. The field heats metal directly inside the crucible. This method is efficient. It melts metal quickly.

The furnace uses a thyristor power system. Thyristors control the electrical power smartly. They adjust power levels precisely. This gives stable melting conditions. Temperature control is accurate. Consistent melting results happen every time. The crucible holds the molten metal. It’s built tough for high temperatures. Crucibles come in different sizes. Choose the size matching your melting needs.

Melting capacity varies. Furnaces handle small batches or large volumes. Power ratings match the capacity. Higher power means faster melting. Look at the kilowatt rating. It tells you the furnace strength. Frequency is important too. Medium frequency operation is common. It works well for many metals.

The furnace body is sturdy steel. It protects the internal parts. A tilting mechanism is included. Tilting pours molten metal safely. Operators stay clear of the heat. Water cooling is essential. It keeps the coil and electronics cool. The system prevents overheating. Safety features protect operators and equipment. Alarms warn about problems. Automatic shutdowns activate if needed.

This machine saves energy. Induction heating is efficient. Less power is wasted as heat. Your power bills stay lower. Production speeds increase. The fast melting cycle helps. You get more metal melted per hour. Maintenance is straightforward. Key parts are accessible. Replacing the crucible is simple. The design focuses on reliability. It runs well for demanding industrial jobs.

(Hot ing Electrical Iron Smelting Oven Thyristor Induction Melting Furnace Stainless Steel Smelter)

Applications of Hot ing Electrical Iron Smelting Oven Thyristor Induction Melting Furnace Stainless Steel Smelter

This thyristor induction melting furnace melts stainless steel fast and well. It uses strong electrical currents to heat metal inside a special coil. You control everything with thyristor power units. These units give you exact heat control. This means you get the metal exactly as hot as needed. It melts quickly and saves energy.

Hot charging scrap metal saves even more money. You put pre-heated metal scrap right into the furnace. This cuts the time needed to reach full melting temperature. Less power gets used. Your operating costs go down. It also helps the furnace lining last longer. Less extreme temperature change means less stress on the lining material.

This furnace works great for many stainless steel jobs. Foundries use it to make new stainless steel castings. It pours precise shapes for parts. Recycling plants melt down old stainless steel scrap. They turn scrap into usable metal bars or ingots again. Factories use it for alloying. They mix elements into the molten steel to create specific grades. The furnace handles small batches perfectly. It also runs large continuous production smoothly. You get clean, consistent molten steel every time. Impurities burn off efficiently. The metal quality stays high. It melts different stainless steel grades reliably. Maintenance stays simple. This machine works hard and lasts long.

Company Profile

PDDN Photoelectron Technology Co., Ltd. is one of the leading enterprises in power electronics technology and power products, which is fully involved in developing solar inverters, transformers, voltage regulators, distribution cabinets, thyristors, modules, diodes, heaters, and other electronic devices or semiconductors. We will be committed to providing users with high-quality, efficient products and considerate service.

It accepts payment via Credit Card, T/T, West Union, and Paypal. PDDN will ship the goods to customers overseas through FedEx, DHL, by sea, or by air. If you want high-quality Hot ing Electrical Iron Smelting Oven Thyristor Induction Melting Furnace Stainless Steel Smelter, please send us inquiries; we will be here to help you.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

Storage Conditions

1) Store in a dry environment at room temperature.

2) Avoid damp and high temperature.

3) Use immediately after opening the inner packing bag.

5 FAQs of Hot ing Electrical Iron Smelting Oven Thyristor Induction Melting Furnace Stainless Steel Smelter

What is this machine?

It melts metal fast using electricity. Electric currents heat the metal inside the furnace crucible. You get molten metal ready for casting.

How hot does it get?

It melts stainless steel easily. Stainless steel needs very high heat. This furnace reaches over 2800°F (1538°C). It melts steel, iron, copper, aluminum too.

How long to melt metal?

Melting speed depends on metal type and amount. A full load of stainless steel might take 40 to 60 minutes. It melts much faster than old fuel furnaces. You save time.

How much metal fits inside?

Models hold different amounts. Common sizes melt 10kg, 25kg, 50kg, or 100kg per batch. Choose the size matching your workshop needs. It fits small foundries well.

Is it safe?

Yes, safety features help. The furnace body stays cooler. Water cooling protects vital parts. Good electrical grounding prevents shocks. Operators must still wear protective gear always. Follow the manual instructions.

(Hot ing Electrical Iron Smelting Oven Thyristor Induction Melting Furnace Stainless Steel Smelter)

REQUEST A QUOTE

RELATED PRODUCTS

Three Phase Series Choke Power Capacitor Dc Harmonic Filter Reactor 50kvar For Inverter

Serial Thyristor For ON/OFF Function Applications

Factory LV 690V Power Factor 0.98 Thyristor Switch Control TSC 200Kvar Capacitor Automatic Compensation Device

Hot AC 220V-380V High Voltage Capacity Energy-saving Controller Stabilizer Thyristor SCR Power Regulator

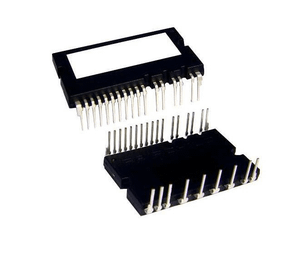

STOCK Electronic components IC Chips mosfet transistor IGBT Power module