Electronic Components Supplier | Transformers, Inductors, Inverters

PRODUCT PARAMETERS

Description

Overview of Hot Runner System Controller

Thyristor is a solid-state semiconductor device composed of four layers of alternating P- and N-type materials. It functions as a bistable switch, conducting current only when triggered by a gate signal, and remains conducting until the voltage across it drops below a certain threshold. Thyristors are widely used for controlling high-power electrical circuits, offering efficient and reliable performance in various industrial and electronic applications.

Features of Hot Runner System Controller

- High current and voltage handling capabilities

- Low on-state voltage drop, reducing power loss

- Fast switching speeds for precise control

- Latching behavior: once triggered, remains conducting without continuous gate signal

- Robust and durable design suitable for harsh environments

- Available in various types (e.g., SCR, TRIAC, GTO) for specific needs

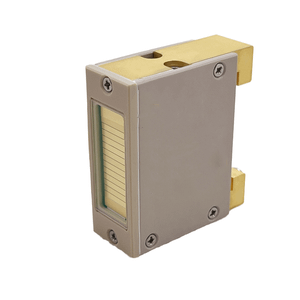

(Hot Runner System Controller)

Specifications of Hot Runner System Controller

Our hot runner controller manages your mold’s temperature level specifically. It manages each home heating zone individually. You established specific temperatures for every nozzle and manifold area. The system maintains temperature levels steady within one level Celsius. This limited control protects against product destruction. It makes certain constant component quality every cycle.

The controller includes a straightforward touchscreen user interface. Operators browse food selections easily. They change settings quickly throughout production. Alarms signal you to concerns like getting too hot or sensing unit faults. The screen shows clear error messages. You determine problems fast. This lessens downtime.

Safety and security works shield both equipment and operators. The system includes thermal cutoff safeguards. These trigger if temperatures exceed secure limitations. Electrical security protects against damages from power rises. All electrical wiring fulfills industrial safety and security criteria. You run with self-confidence.

Longevity issues in harsh factory atmospheres. Our controller uses a rugged steel housing. It stands up to dirt, dampness, and impacts. Internal elements are industrial-grade. They endure resonance and temperature swings common near molding machines. Dependability is integrated.

Interaction options give adaptability. Link by means of typical industrial protocols like Ethernet/IP or Modbus. This connects the controller directly to your manufacturing facility network. You check and manage temperature levels from another location from a central station. Assimilation with plant systems is basic. Manufacturing information streams smoothly.

Accurate timing control handles shutoff gates. You set open and close sequences accurately. Synchronization with the molding equipment is critical. The controller makes certain excellent timing for every single shot. This eliminates flaws from early or late gateway actuation. Constant cycles are assured.

(Hot Runner System Controller)

Applications of Hot Runner System Controller

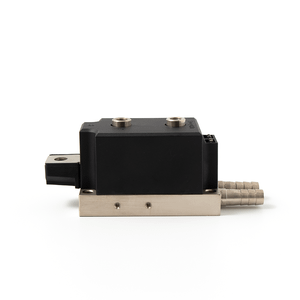

Hot runner system controllers manage the temperature level inside mold and mildews. They are important for precise plastic shot molding. These controllers maintain the plastic warm and running correctly inside the hot jogger manifold and nozzles. Consistent temperature level control is the primary work. This stops plastic from cold prematurely. It stops obstructions in the networks. It makes sure the plastic loads every tooth cavity evenly. Excellent temperature control means better part quality.

Controllers handle several home heating areas independently. Each nozzle and manifold area commonly has its own area. The controller changes power to each area separately. This makes up for warm loss variations. It takes care of different material circulation rates. It handles complex mold and mildew layouts. Multi-zone control is essential for large molds. It is crucial for mold and mildews with numerous tooth cavities.

Controllers provide real-time monitoring and adjustment. Operators see the exact temperature of each zone. They see this on a display screen. The controller automatically readjusts power if temperatures wander. This preserves stability throughout long production runs. Steady temperatures decrease scrap parts. They boost consistency part-to-part. They save material expenses.

Controllers assist with procedure optimization. They record temperature information in time. This data assists fix troubles. It aids fine-tune settings for new mold and mildews. It assists locate the most effective settings for different materials. Faster arrangement times result. Much less device downtime happens.

Controllers often connect directly to the shot molding machine. They connect with the equipment’s central control system. This allows coordinated start-up and shutdown sequences. It makes it possible for remote tracking from a central terminal. It offers alarm systems for temperature level mistakes. Integration boosts general procedure integrity. It simplifies operation for the customer. It shields the mold and mildew from damage because of temperature errors.

Company Profile

PDDN Photoelectron Technology Co., Ltd. is one of the leading enterprises in power electronics technology and power products, which is fully involved in developing solar inverters, transformers, voltage regulators, distribution cabinets, thyristors, modules, diodes, heaters, and other electronic devices or semiconductors. We will be committed to providing users with high-quality, efficient products and considerate service.

It accepts payment via Credit Card, T/T, West Union, and Paypal. PDDN will ship the goods to customers overseas through FedEx, DHL, by sea, or by air. If you want high-quality Hot Runner System Controller, please send us inquiries; we will be here to help you.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

Storage Conditions

1) Store in a dry environment at room temperature.

2) Avoid damp and high temperature.

3) Use immediately after opening the inner packing bag.

5 FAQs of Hot Runner System Controller

What is a hot runner system controller?

A hot runner system controller manages the temperature inside a hot runner mold. It connects to heaters and sensors inside the mold channels. The controller keeps the plastic material molten as it travels to the mold cavities. Precise temperature control is critical for good part quality.

Why do I need a controller?

Without a controller, plastic in the hot runner channels cools down. Solid plastic blocks the channels. This causes short shots or inconsistent part filling. The controller prevents material freezing. It ensures plastic flows smoothly every time the mold opens. Consistent flow means consistent parts.

What problems do controllers solve?

Controllers fix common temperature issues. They prevent overheating that degrades plastic. They stop underheating that causes frozen nozzles. They manage heater failures. They warn operators about thermocouple problems. Good controllers maintain stable temperatures cycle after cycle. This stability reduces scrap and downtime.

How does it control temperature?

The controller constantly reads temperature signals from sensors in the mold. It compares this reading to the setpoint you programmed. The controller sends power to the heaters if the temperature is too low. It reduces power if the temperature gets too high. This adjustment happens very fast. It keeps the temperature within a tight range.

How do I choose the right controller?

Consider your mold first. Count the number of heating zones needing control. Check the power requirements for each zone. Decide if you need basic control or advanced features like data logging. Think about the production environment. Choose a controller robust enough for factory conditions. Reliable support from the manufacturer is important. The right controller matches your mold’s needs and your production goals.

(Hot Runner System Controller)

REQUEST A QUOTE

RELATED PRODUCTS

Renewable Energy Hydroelectric Power Generation Alternators Hydro Water Generator for Hydropower Plants

Factory Direct Premium Quality 100mm/120mm Toroidal Nanocrystalline Transformer Soft Iron Core Common Mode Choke

Three Phase Series Choke Power Capacitor Dc Harmonic Filter Reactor 50kvar For Inverter

High dV/dt Capability 320A Phase Control Thyristors stud thyristor

Factory Direct Premium Quality 100mm/120mm Toroidal Nanocrystalline Transformer Soft Iron Core Common Mode Choke