Electronic Components Supplier | Transformers, Inductors, Inverters

PRODUCT PARAMETERS

Description

Overview of Hot Runner System Controller with PT100 Precision Temperature Control

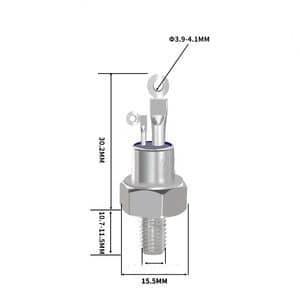

Thyristor is a solid-state semiconductor device composed of four layers of alternating P- and N-type materials. It functions as a bistable switch, conducting current only when triggered by a gate signal, and remains conducting until the voltage across it drops below a certain threshold. Thyristors are widely used for controlling high-power electrical circuits, offering efficient and reliable performance in various industrial and electronic applications.

Features of Hot Runner System Controller with PT100 Precision Temperature Control

- High current and voltage handling capabilities

- Low on-state voltage drop, reducing power loss

- Fast switching speeds for precise control

- Latching behavior: once triggered, remains conducting without continuous gate signal

- Robust and durable design suitable for harsh environments

- Available in various types (e.g., SCR, TRIAC, GTO) for specific needs

(Hot Runner System Controller with PT100 Precision Temperature Control)

Specifications of Hot Runner System Controller with PT100 Precision Temperature Control

This controller handles hot runner systems. It makes use of PT100 sensors for specific temperature level control. PT100 sensors offer really exact readings. That matters for constant plastic molding. Control temperatures specifically where needed. This protects against material problems like burning or incomplete filling.

See all temperature zones on one clear screen. The display reveals real-time information. Monitor whatever conveniently throughout manufacturing. Change setups swiftly if called for. The user interface is simple for operators. No complicated menus or intricate steps.

Constructed solid for manufacturing facility conditions. This system deals with dust, vibration, and electrical noise reliably. Anticipate steady performance day in day out. It minimizes unanticipated closures. Much less downtime means extra parts produced.

Safety functions are included. The system spots issues like overheating or sensing unit failure. It informs drivers instantly. Automatic shutdowns stop damages if crucial faults happen. This shields your mold and mildews and equipment. It quits problems prior to they start.

Link to various other equipments or plant networks. Use typical industrial communication protocols. Gather production data effectively. Boost total procedure monitoring and coverage. Configuration is straightforward for technicians.

Accuracy control boosts component high quality. Waste less material. Minimize energy use. This controller assists achieve efficient molding cycles. It’s the ideal selection for demanding manufacturing.

(Hot Runner System Controller with PT100 Precision Temperature Control)

Applications of Hot Runner System Controller with PT100 Precision Temperature Control

Hot runner system controllers with PT100 precision temperature control are essential devices for contemporary injection molding. These controllers handle the temperature of the warm jogger nozzles and manifolds very precisely. This accuracy comes from utilizing PT100 temperature sensing units. PT100 sensors give extremely reputable temperature level readings. This degree of control is crucial for several demanding applications.

Clinical device manufacturing demands best part quality. Regular melt temperature level prevents problems like burns or cool slugs. Controllers with PT100 sensing units keep the precise temperature needed. This guarantees every component satisfies strict clinical standards. It decreases scrap rates substantially.

Thin-wall product packaging requires exceptionally rapid cycle times. Thaw temperature level must be flawlessly steady. Any kind of variation triggers circulation problems. Precise PT100 control keeps the melt moving smoothly. This permits high-speed production without problems. It lessens material waste.

Automotive components frequently use engineering resins. These products are sensitive to temperature changes. Even tiny inconsistencies can create warping or weak points. A PT100-based controller keeps the specific heat profile. This guarantees dimensional precision and part strength. Complicated geometries create properly.

Electronic devices elements entail little, detailed attributes. Maintaining accurate thaw temperature level is vital. As well hot problems fragile inserts. Too cool causes short shots. PT100 controllers supply the required security. This shields delicate components during molding. Manufacturing returns enhance.

Company Profile

PDDN Photoelectron Technology Co., Ltd. is one of the leading enterprises in power electronics technology and power products, which is fully involved in developing solar inverters, transformers, voltage regulators, distribution cabinets, thyristors, modules, diodes, heaters, and other electronic devices or semiconductors. We will be committed to providing users with high-quality, efficient products and considerate service.

It accepts payment via Credit Card, T/T, West Union, and Paypal. PDDN will ship the goods to customers overseas through FedEx, DHL, by sea, or by air. If you want high-quality Hot Runner System Controller with PT100 Precision Temperature Control, please send us inquiries; we will be here to help you.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

Storage Conditions

1) Store in a dry environment at room temperature.

2) Avoid damp and high temperature.

3) Use immediately after opening the inner packing bag.

5 FAQs of Hot Runner System Controller with PT100 Precision Temperature Control

What does this controller actually do?

It controls the temperature in your hot runner system. The controller keeps every zone at its exact set temperature. This happens during the entire molding cycle. Consistent temperature is critical for good part quality.

Why is PT100 temperature control important?

PT100 sensors are very accurate. They measure temperature precisely. Standard sensors might drift over time. PT100 sensors stay reliable. This accuracy means better control over your melt. You get more consistent parts. You waste less material.

Can it stop problems like drooling or freezing?

Yes, precise temperature control helps prevent these issues. The controller reacts fast to any temperature change. It stops the melt from getting too hot. Too hot causes drooling. It stops the melt from getting too cold. Too cold causes freezing. Stable temperature means smoother production.

Is setting it up difficult?

Setting it up is straightforward. The controller has a clear interface. You enter your desired temperatures for each zone. The PT100 sensors give true readings. The controller does the rest. Operators find it easy to use daily. Training time is minimal.

How much maintenance does it need?

These controllers need very little maintenance. The PT100 sensors are robust. The controller itself is built for factory conditions. Regular checks are smart. Look for any loose wires. Keep the display clean. The system is designed for long, trouble-free operation.

(Hot Runner System Controller with PT100 Precision Temperature Control)

REQUEST A QUOTE

RELATED PRODUCTS

Reactor Capacitor Thyristor Switched Capacitor Power Factor Capacitor Bank

Factory Thyristor SCR KK KP 300A 500A 800A 1000A 1200A 1500A 1800A 2000A High Quality Thyristor For

Intelligent Thyristor SCR Digital Display Thermostat Voltage Regulator Stabilizer

Three Phase Power Control Unit Thyristor (SCR Power Controller) Ramp / Soak Controllers

High Quality Thyristor Automatic Submerged Arc Welding Machine Easy Operation Thyristor Welder