Electronic Components Supplier | Transformers, Inductors, Inverters

PRODUCT PARAMETERS

Description

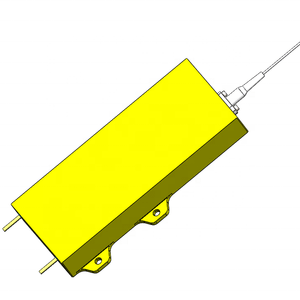

Overview of Induction Heating Furnace

Thyristor is a solid-state semiconductor device composed of four layers of alternating P- and N-type materials. It functions as a bistable switch, conducting current only when triggered by a gate signal, and remains conducting until the voltage across it drops below a certain threshold. Thyristors are widely used for controlling high-power electrical circuits, offering efficient and reliable performance in various industrial and electronic applications.

Features of Induction Heating Furnace

- High current and voltage handling capabilities

- Low on-state voltage drop, reducing power loss

- Fast switching speeds for precise control

- Latching behavior: once triggered, remains conducting without continuous gate signal

- Robust and durable design suitable for harsh environments

- Available in various types (e.g., SCR, TRIAC, GTO) for specific needs

(Induction Heating Furnace)

Specifications of Induction Heating Furnace

Induction home heating heaters melt metal quickly. They use electrical energy to develop heat inside the steel itself. This approach is very efficient. These furnaces are available in various power degrees. Power generally ranges from a couple of kilowatts to a number of megawatts. The specific power you require relies on your metal kind and just how much you wish to thaw. Temperature level control is exact. Heating systems can reach over 1800 degrees Celsius. This suits most metals. The melting capacity differs. Small heating systems manage a few kilograms. Large commercial ones manage tons of material. The heating system crucible holds the steel. Crucibles are made from strong materials like ceramic or graphite. They stand up to severe heat. The induction coil borders the crucible. It carries the high-frequency electric existing. This present produces the magnetic field for home heating. Cooling is essential. Heaters have water air conditioning systems. These systems cool the coil and essential power parts. Overheating damages the devices. The electric system uses solid-state power materials. These are modern-day and trusted. They regulate the power mosting likely to the coil. Regularity modifications based upon the application. Greater regularities warmth smaller components much faster. Lower regularities permeate deeper into big metal quantities. Operation is normally simple. Modern furnaces have great control panels. Operators set the preferred temperature level and power. The heater maintains these setups. Security features are built-in. Systems display water flow and temperature. They closed down the heater if something is wrong. This safeguards the equipment and the people nearby. The furnace framework is durable. It sustains the heavy crucible and coil setting up. The layout focuses on stability during operation. These heaters work in many sectors. Shops utilize them for melting. Forge stores utilize them for heating metal prior to forming. Maintenance is very important. Normal examine the coil, crucible, and cooling down system protect against failings.

(Induction Heating Furnace)

Applications of Induction Heating Furnace

Induction home heating heaters heat steel making use of electrical power and magnets. They work quickly and specifically. Manufacturing facilities use them for numerous crucial work.

Steel shops melt scrap metal or raw materials. The heater transforms strong metal right into fluid. Workers pour this liquid steel into molds. The molds shape the steel into useful components. This method saves power. It melts steel cleaner than old coal heating systems.

Forging shops warm metal bars or blocks before forming. The heating system makes the metal soft adequate to press or hammer. Employees develop the hot metal right into solid parts like gears or axles. This home heating happens rapidly. It just heats up the specific location needed.

Vehicle makers rely on these heating systems. They set the surface areas of parts like crankshafts or equipments. The heater heats up simply the outer layer. Employees after that cool it fast. This makes the surface area very difficult and resistant to wear. The within remains tough. This process makes auto parts last much longer. Manufacturing facilities likewise heat metal items for brazing. This signs up with parts with each other strongly inside engines or transmissions.

Aircraft home builders need strong, reliable components. They utilize induction home heating for specific tasks. The heater heats up vital components for treating. This boosts the steel’s stamina and durability. It makes sure aircraft parts execute securely.

Electronics factories use smaller induction heaters. They affix small components to motherboard. The heat thaws solder extremely fast. It links components without damaging delicate electronic devices. Jewelers also use tiny induction units. They melt gold, silver, or platinum for casting rings or various other items. The warm is clean and controlled.

Company Profile

PDDN Photoelectron Technology Co., Ltd. is one of the leading enterprises in power electronics technology and power products, which is fully involved in developing solar inverters, transformers, voltage regulators, distribution cabinets, thyristors, modules, diodes, heaters, and other electronic devices or semiconductors. We will be committed to providing users with high-quality, efficient products and considerate service.

It accepts payment via Credit Card, T/T, West Union, and Paypal. PDDN will ship the goods to customers overseas through FedEx, DHL, by sea, or by air. If you want high-quality Induction Heating Furnace, please send us inquiries; we will be here to help you.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

Storage Conditions

1) Store in a dry environment at room temperature.

2) Avoid damp and high temperature.

3) Use immediately after opening the inner packing bag.

5 FAQs of Induction Heating Furnace

What makes an induction furnace work?

It uses magnets and electricity. Electricity flows through a coil. This creates a strong magnetic field. The field heats metal inside the coil fast. No flames touch the metal. The heat comes from inside the metal itself.

Does this furnace save energy?

Yes, it usually uses less power than old furnaces. It heats only the metal piece. The furnace itself stays cooler. Less heat escapes into the air. This cuts energy costs. Power gets used more efficiently.

How exact is the temperature control?

It controls heat very precisely. You set the exact temperature needed. The system adjusts power instantly. This keeps the heat steady. Consistent results happen every time. Different metals need specific temperatures. This furnace hits them accurately.

How fast does it heat metal?

It heats metal incredibly fast. Seconds or minutes are typical. It depends on the metal type and size. Small pieces heat almost instantly. Production speeds increase significantly. Waiting for long heat-up times ends.

What metals can it heat?

It heats many common metals. Steel, iron, copper, brass, aluminum all work. It heats only metals that conduct electricity. Non-metallic materials won’t heat up. The furnace handles various shapes and sizes. Bars, rods, sheets, and complex parts heat effectively.

(Induction Heating Furnace)

REQUEST A QUOTE

RELATED PRODUCTS

Billet Electric Induction Heating Furnace

High Quality Thyristor Automatic Submerged Arc Welding Machine Easy Operation Thyristor Welder

3 Phase Thyristor Regulator 220v 480VAC SCR Power Regulator Voltage Controller

SCR 100kw Static Thyristor Igbt 3 Phase Static Voltage Regulator Stabilizer 150kva Static Avr Automatic Voltage Regulator

Metal Induction Heating Furnace