Electronic Components Supplier | Transformers, Inductors, Inverters

PRODUCT PARAMETERS

Description

Overview of Induction Heating Furnace for Rebar Reformed Material Production Line

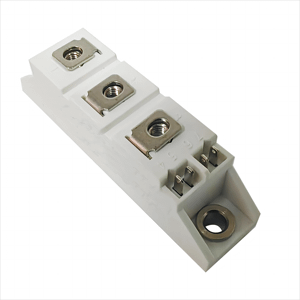

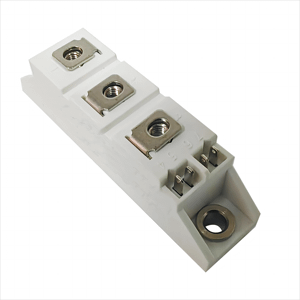

Thyristor is a solid-state semiconductor device composed of four layers of alternating P- and N-type materials. It functions as a bistable switch, conducting current only when triggered by a gate signal, and remains conducting until the voltage across it drops below a certain threshold. Thyristors are widely used for controlling high-power electrical circuits, offering efficient and reliable performance in various industrial and electronic applications.

Features of Induction Heating Furnace for Rebar Reformed Material Production Line

- High current and voltage handling capabilities

- Low on-state voltage drop, reducing power loss

- Fast switching speeds for precise control

- Latching behavior: once triggered, remains conducting without continuous gate signal

- Robust and durable design suitable for harsh environments

- Available in various types (e.g., SCR, TRIAC, GTO) for specific needs

(Induction Heating Furnace for Rebar Reformed Material Production Line)

Specifications of Induction Heating Furnace for Rebar Reformed Material Production Line

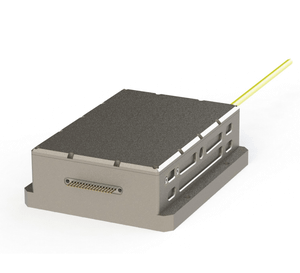

This induction heating furnace heats steel rebars fast for your reformed material line. It gets rebars ready for reshaping or tempering. The furnace uses electromagnetic fields for heating. This method is direct and efficient.

Power capacity ranges from 500 kW to 2000 kW. You choose based on your production speed and rebar size. Heating temperatures reach up to 1200°C. Temperature control is precise. This ensures consistent material properties every time.

Heating speed adjusts easily. It handles different rebar diameters smoothly. Common diameters are 12mm to 40mm. Lengths up to 12 meters work fine. The furnace fits continuous or batch processing.

Energy efficiency is a key feature. Power factor correction is standard. It minimizes wasted electricity. Water cooling protects vital parts like the coil and electronics. Cooling systems are reliable.

The furnace structure is heavy-duty steel. It handles tough industrial conditions. Installation needs a solid foundation. Electrical connections require three-phase power. Water supply for cooling is essential.

Operation uses a modern PLC control system. The interface is simple. Operators set and monitor temperature easily. They adjust speed without trouble. Safety systems prevent overheating. They protect against electrical faults.

Maintenance is straightforward. Access points are clear. Replacing coils or parts is quick. This furnace integrates well into automated lines. Sensors link with other machines. It sends real-time data to plant systems.

Output matches your production targets. Consistent heating quality is guaranteed. It reduces scrap material significantly. This furnace is a reliable core component for reformed rebar.

(Induction Heating Furnace for Rebar Reformed Material Production Line)

Applications of Induction Heating Furnace for Rebar Reformed Material Production Line

Induction heating furnaces play a vital role in rebar reformed material production lines. They heat metal extremely fast and efficiently. This process is essential for preparing rebars before reshaping. The furnace heats the rebar ends precisely. Workers need this for upset forging or heading operations. Proper heating makes the metal soft enough to form. It prevents cracking or defects during shaping. Temperature control is critical. Induction furnaces manage this accurately. Consistent heat ensures every rebar end meets specifications. This results in reliable, high-quality reformed rebar products.

These furnaces also melt scrap metal efficiently. The melted metal becomes raw material for new rebars. This is a key part of recycling within the production line. Induction melting is much faster than traditional methods. It uses less energy too. This saves significant operating costs for the factory. The furnace design minimizes heat loss. Surrounding areas stay cooler. This improves the overall working environment for operators.

Operational benefits are clear. Induction furnaces start heating instantly. There’s no waiting for a furnace to warm up. Production can begin immediately. The heating process is easily automated. This fits perfectly into modern production lines. Integration with robotic systems is straightforward. This allows for continuous, high-volume rebar reforming. Maintenance needs are generally lower compared to fuel-fired furnaces. The furnace uses electricity to generate heat directly inside the metal. This direct heating method is inherently efficient. It saves energy and lowers production costs. Consistent product quality is easier to achieve. The process is also cleaner. There are no harmful emissions from burning fuel. This supports better environmental practices.

Company Profile

PDDN Photoelectron Technology Co., Ltd. is one of the leading enterprises in power electronics technology and power products, which is fully involved in developing solar inverters, transformers, voltage regulators, distribution cabinets, thyristors, modules, diodes, heaters, and other electronic devices or semiconductors. We will be committed to providing users with high-quality, efficient products and considerate service.

It accepts payment via Credit Card, T/T, West Union, and Paypal. PDDN will ship the goods to customers overseas through FedEx, DHL, by sea, or by air. If you want high-quality Induction Heating Furnace for Rebar Reformed Material Production Line, please send us inquiries; we will be here to help you.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

Storage Conditions

1) Store in a dry environment at room temperature.

2) Avoid damp and high temperature.

3) Use immediately after opening the inner packing bag.

5 FAQs of Induction Heating Furnace for Rebar Reformed Material Production Line

What is induction heating for rebar?

It heats steel bars fast using magnetic fields. Electricity creates these fields inside the furnace coil. The rebar heats up directly as it passes through. This method is very controlled.

How quickly can it heat rebar?

These furnaces heat rebar incredibly fast. They can reach forging temperatures in seconds or minutes. Rates often exceed 500°C per minute. This speed keeps production lines moving efficiently.

Is it energy efficient?

Yes, induction heating is highly efficient. It transfers energy directly into the rebar. Little heat escapes into the air. This direct method uses less power than gas furnaces or older electric types. It cuts energy costs.

How precise is the temperature control?

Temperature control is very precise. The system constantly monitors the heat. It adjusts power instantly. This ensures every section of rebar reaches the exact temperature needed. Consistent quality is guaranteed.

What maintenance does it need?

Maintenance is generally simple. Regularly check the electrical connections and cooling water system. Keep the coil area clean. Replace worn parts like insulation or filters per the schedule. Proper care ensures long life and reliable operation.

(Induction Heating Furnace for Rebar Reformed Material Production Line)

REQUEST A QUOTE

RELATED PRODUCTS

High Quality Three-Phase SCR TIRISTOR Power Regulator Cabinet for Voltage Control AC Current Type

200A 300V Thyristor Rectifier Use for Electrophoresis

thyristor Control Board Ir thyristor Bridge Rectifier IRKT106/14

Thyristor driven optocoupler

200A 300V Thyristor Controlled Rectifier for Anodic Electrophoretic Coating