Electronic Components Supplier | Transformers, Inductors, Inverters

PRODUCT PARAMETERS

Description

Overview of Induction Heating Furnace for Steel Wire Rod Reformed Material

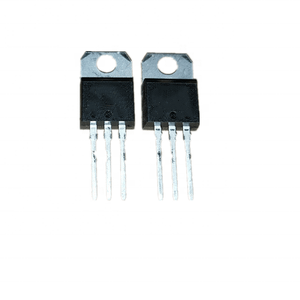

Thyristor is a solid-state semiconductor device composed of four layers of alternating P- and N-type materials. It functions as a bistable switch, conducting current only when triggered by a gate signal, and remains conducting until the voltage across it drops below a certain threshold. Thyristors are widely used for controlling high-power electrical circuits, offering efficient and reliable performance in various industrial and electronic applications.

Features of Induction Heating Furnace for Steel Wire Rod Reformed Material

- High current and voltage handling capabilities

- Low on-state voltage drop, reducing power loss

- Fast switching speeds for precise control

- Latching behavior: once triggered, remains conducting without continuous gate signal

- Robust and durable design suitable for harsh environments

- Available in various types (e.g., SCR, TRIAC, GTO) for specific needs

(Induction Heating Furnace for Steel Wire Rod Reformed Material)

Specifications of Induction Heating Furnace for Steel Wire Rod Reformed Material

This induction heating furnace heats steel wire rod reformed material. It prepares the material for reforming processes. The furnace uses electromagnetic induction. This method heats the metal directly and quickly. You get consistent results every time.

The furnace offers high power output. Power levels range from 100 kW to 2000 kW. This depends on your production needs. The operating frequency is medium. This frequency penetrates the wire rod well. It ensures uniform heating through the entire cross-section. Heating capacity suits continuous processing lines. It handles wire rod diameters typically from 5mm to 20mm. Line speeds match your required throughput.

Precise temperature control is critical. The furnace achieves temperatures up to 1100°C. This meets the needs of annealing or tempering. Advanced PLC systems manage the heating. Sensors monitor temperature constantly. The system adjusts power instantly. This keeps the exact temperature you set. Uniformity is very good across the rod.

Efficient water cooling protects the coil. Cooling systems prevent overheating. They keep the furnace running reliably. Operators control everything from a simple HMI screen. They set parameters easily. They monitor the process in real-time. Safety features are integrated. They protect both the equipment and your people.

Material handling is straightforward. The furnace integrates with existing conveyors. It works with roller tables or similar systems. Minimal manual handling is needed. This boosts efficiency. Maintenance requirements are low. The design focuses on easy access to key parts. This reduces downtime. Robust construction ensures long service life. The furnace handles tough industrial conditions.

(Induction Heating Furnace for Steel Wire Rod Reformed Material)

Applications of Induction Heating Furnace for Steel Wire Rod Reformed Material

Induction heating furnaces work well for steel wire rod reformed material. Workers need specific heat treatments during production. These furnaces deliver precise temperature control. This is vital for consistent product quality. They heat the steel wire rods quickly and directly. The heat comes from inside the material itself. This method is very efficient. It uses less power than older furnace types.

One major use is annealing. The furnace heats the wire rods to a set temperature. Then it cools them slowly. This process makes the steel softer. Soft steel is easier to draw into thinner wire. It also improves ductility. The wire becomes less brittle. This is important for final product performance.

Hardening is another key application. The furnace heats the rods fast to a high temperature. Workers then quench them rapidly in oil or water. This makes the steel much harder. Hardened wire rods are strong. They resist wear better. This is needed for tough applications like springs or cables.

Tempering often follows hardening. The furnace reheats the hardened rods to a lower temperature. This reduces brittleness caused by hardening. It keeps most of the hardness. The steel gains better toughness. It handles stress better without breaking.

These furnaces also prepare wire rods for coating. Surface treatments like galvanizing need clean, preheated surfaces. Induction heating provides fast, uniform preheating. This ensures coatings stick properly. It improves corrosion resistance for the final wire product.

Preheating before forming is common too. Cold wire rods are hard to shape. The furnace heats them just enough. This makes forming easier. It reduces the force needed. It also lowers the risk of cracks during shaping.

Company Profile

PDDN Photoelectron Technology Co., Ltd. is one of the leading enterprises in power electronics technology and power products, which is fully involved in developing solar inverters, transformers, voltage regulators, distribution cabinets, thyristors, modules, diodes, heaters, and other electronic devices or semiconductors. We will be committed to providing users with high-quality, efficient products and considerate service.

It accepts payment via Credit Card, T/T, West Union, and Paypal. PDDN will ship the goods to customers overseas through FedEx, DHL, by sea, or by air. If you want high-quality Induction Heating Furnace for Steel Wire Rod Reformed Material, please send us inquiries; we will be here to help you.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

Storage Conditions

1) Store in a dry environment at room temperature.

2) Avoid damp and high temperature.

3) Use immediately after opening the inner packing bag.

5 FAQs of Induction Heating Furnace for Steel Wire Rod Reformed Material

Induction Heating Furnace for Steel Wire Rod Reformed Material – Key Questions

How does this furnace heat steel wire rods?

It uses powerful magnets. These magnets create electric currents inside the wire rod itself. The rod heats up fast from the inside. This is direct heating. There is no flame or external heating element touching the metal.

Why choose induction for reformed wire rods?

Induction heating gives very even heat. This is critical for reformed material. Consistent heat ensures the rod’s structure changes correctly. The process is fast. It saves time. The quality of the final wire rod improves significantly. Strength and flexibility are better controlled.

Is this furnace energy efficient?

Yes, it uses power well. Induction heats only the metal rod. Little energy is wasted heating the air around it or the furnace structure. The heating happens quickly. Less time heating means less total energy used. This lowers operating costs.

How precise is the temperature control?

Control is very accurate. Modern systems monitor the rod’s temperature constantly. They adjust the power instantly. This keeps the exact temperature needed. Precise temperature is vital for consistent material properties in reformed steel wire.

What about safety and maintenance?

These furnaces are safer. No open flames are present. Operators face less risk. The design is often simpler than fuel-fired furnaces. Fewer moving parts exist. This usually means less maintenance is needed. Downtime is reduced.

(Induction Heating Furnace for Steel Wire Rod Reformed Material)

REQUEST A QUOTE

RELATED PRODUCTS

Stud Welding Machine

New IP67product 12V24V Thyristor Dimming LED Waterproof Power Supply 60W-400W Outdoor Constant Voltage Drive Switch Power Supply

3 Phase 400V SCR Power Regulator Controller 100A Voltage Regulator SSR Solid State Relay 0-10V 4-20mA

Disc type SCR / phase control thyristor / fast thyristor

3 Phase Thyristor Regulator 220v 480VAC SCR Power Regulator Voltage Controller