Electronic Components Supplier | Transformers, Inductors, Inverters

PRODUCT PARAMETERS

Description

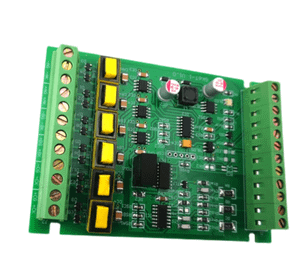

Overview of Intelligent Plug-in 1-zone PID Hot Runner Temperature Controller Suitable for Plastic Mold Hot Runner System

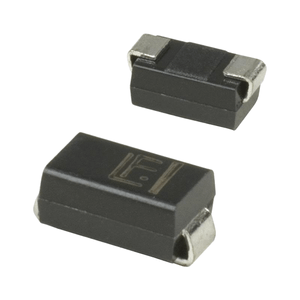

Thyristor is a solid-state semiconductor device composed of four layers of alternating P- and N-type materials. It functions as a bistable switch, conducting current only when triggered by a gate signal, and remains conducting until the voltage across it drops below a certain threshold. Thyristors are widely used for controlling high-power electrical circuits, offering efficient and reliable performance in various industrial and electronic applications.

Features of Intelligent Plug-in 1-zone PID Hot Runner Temperature Controller Suitable for Plastic Mold Hot Runner System

- High current and voltage handling capabilities

- Low on-state voltage drop, reducing power loss

- Fast switching speeds for precise control

- Latching behavior: once triggered, remains conducting without continuous gate signal

- Robust and durable design suitable for harsh environments

- Available in various types (e.g., SCR, TRIAC, GTO) for specific needs

(Intelligent Plug-in 1-zone PID Hot Runner Temperature Controller Suitable for Plastic Mold Hot Runner System)

Specifications of Intelligent Plug-in 1-zone PID Hot Runner Temperature Controller Suitable for Plastic Mold Hot Runner System

This Intelligent Plug-in PID Hot Runner Temperature Controller manages one heating zone in your plastic mold hot runner system. It plugs directly into the system, saving space and simplifying installation. Mounting happens on standard DIN rails, common in industrial cabinets.

It controls temperature very precisely using PID technology. PID constantly adjusts the heater power. This keeps the temperature exactly where you set it. Precise temperature control is vital for consistent plastic part quality. It prevents material degradation or incomplete filling. The temperature range covers typical plastic processing needs, likely from 0°C up to 400°C. Accuracy is high, typically within ±0.5°C of the set point.

The controller works with standard thermocouples, like K-type or J-type. These sensors feed back real-time temperature data. It provides clear output for controlling the heater cartridge. You set the desired temperature easily using its interface. Alarms notify you of problems immediately. Common alarms include sensor failure, overheating, or communication loss. This helps prevent damage to molds or material.

It supports communication protocols like RS485. This allows connection to a central control system or host computer. You can monitor and adjust settings remotely. Some models offer features like automatic tuning. Auto-tuning optimizes the PID settings for your specific mold. This saves setup time and improves performance quickly.

Robust construction ensures reliability in the tough factory environment. It handles electrical noise and vibration well. Efficient operation helps save energy costs. Stable temperature control reduces scrap parts and downtime. This controller is a key part for reliable, efficient hot runner operation.

(Intelligent Plug-in 1-zone PID Hot Runner Temperature Controller Suitable for Plastic Mold Hot Runner System)

Applications of Intelligent Plug-in 1-zone PID Hot Runner Temperature Controller Suitable for Plastic Mold Hot Runner System

This Intelligent Plug-in 1-zone PID Hot Runner Temperature Controller manages heat precisely in one section of your plastic mold hot runner. It’s made for injection molding machines. It ensures plastic melts correctly and flows smoothly into the mold cavity. This is vital for making good plastic parts consistently.

The PID control is key. It constantly checks the actual temperature against your set point. It then adjusts the heater power instantly. This stops temperature swings. It keeps the melt stable. Stable temperatures mean fewer defects in your parts. You get better quality overall.

Starting up the machine is easier. The controller helps heat the hot runner zone steadily. It avoids overheating the plastic during warm-up. This saves time. It also protects sensitive materials from damage. You waste less plastic at the start of production.

It handles different plastic resins well. Each material needs specific heat. The controller gives tight temperature control. This is crucial for tricky materials like engineering plastics. It prevents burning or incomplete melting. Your parts come out right, even with difficult plastics.

Problems are easier to spot. The controller watches for heater or sensor issues. It gives clear warnings if something goes wrong. This helps you fix things fast. You avoid costly mold damage. You also avoid making bad parts for long periods.

The plug-in design makes setup simple. It fits standard systems easily. Operators find it straightforward to use daily. You save time on installation and training. The controller is reliable. It keeps your molding process running smoothly hour after hour. This leads to more parts made faster.

Company Profile

PDDN Photoelectron Technology Co., Ltd. is one of the leading enterprises in power electronics technology and power products, which is fully involved in developing solar inverters, transformers, voltage regulators, distribution cabinets, thyristors, modules, diodes, heaters, and other electronic devices or semiconductors. We will be committed to providing users with high-quality, efficient products and considerate service.

It accepts payment via Credit Card, T/T, West Union, and Paypal. PDDN will ship the goods to customers overseas through FedEx, DHL, by sea, or by air. If you want high-quality Intelligent Plug-in 1-zone PID Hot Runner Temperature Controller Suitable for Plastic Mold Hot Runner System, please send us inquiries; we will be here to help you.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

Storage Conditions

1) Store in a dry environment at room temperature.

2) Avoid damp and high temperature.

3) Use immediately after opening the inner packing bag.

5 FAQs of Intelligent Plug-in 1-zone PID Hot Runner Temperature Controller Suitable for Plastic Mold Hot Runner System

What is this Intelligent Plug-in PID Controller?

This Intelligent Plug-in 1-zone PID controller manages heat for one section of a plastic mold hot runner. It uses PID technology. PID constantly adjusts power to keep the temperature exactly where you set it. This prevents plastic quality problems. It plugs directly into the mold. This saves space near the machine.

How do I install it?

Installation is simple. Plug the controller directly into the hot runner system’s socket. Connect the thermocouple. The thermocouple is the temperature sensor. Connect the power supply. Basic wiring is needed. The manual shows the exact steps. Follow the manual carefully. Ensure connections are tight and correct.

How accurate is the temperature control?

Temperature control is very precise. PID technology constantly makes tiny adjustments. It reacts fast to temperature changes. This keeps the temperature within ±1°C of your set point. Stable temperature is critical. Stable temperature makes good plastic parts. It prevents flaws like burns or weak spots.

What alarms does it have?

The controller has built-in safety alarms. It watches for problems. It detects if the thermocouple breaks. It detects if the actual temperature is too high. It detects if the actual temperature is too low. The controller shows an error code. It might shut off power automatically. This protects your mold and plastic.

Does it work with any hot runner system?

Check compatibility first. This plug-in controller fits many standard 1-zone hot runner systems. Confirm the socket type matches. Confirm the voltage matches your power supply. Confirm the thermocouple type is correct. The manual lists compatible systems. Contact the supplier if unsure. Using the wrong controller risks damage.

(Intelligent Plug-in 1-zone PID Hot Runner Temperature Controller Suitable for Plastic Mold Hot Runner System)

REQUEST A QUOTE

RELATED PRODUCTS

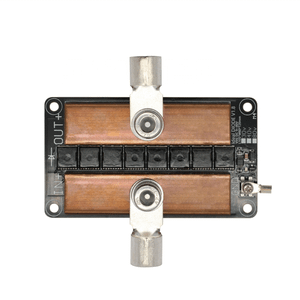

IGBT Module Igbt Power Modules Transistor Electronics Igbt For Motor

Thyristor stud types of diode stud thyristor

Phase Control Thyristor SCR for High Power Converter Disc Type Phase controlled Thyristor

Capsule Type Phase Control Thyristor SCR for Railway

Original Discrete Semiconductor Products Thyristors TRIACs TRIAC (we support bom list)