Electronic Components Supplier | Transformers, Inductors, Inverters

PRODUCT PARAMETERS

Description

Overview of KR-200/350/500 Heavy Industry Thyristor CO2 MAG Gas Shielded Welding Machine MIG Welding Machine

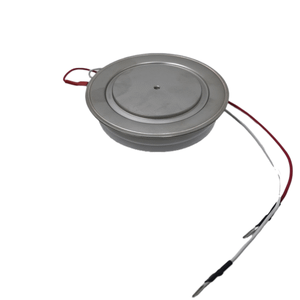

Thyristor is a solid-state semiconductor device composed of four layers of alternating P- and N-type materials. It functions as a bistable switch, conducting current only when triggered by a gate signal, and remains conducting until the voltage across it drops below a certain threshold. Thyristors are widely used for controlling high-power electrical circuits, offering efficient and reliable performance in various industrial and electronic applications.

Features of KR-200/350/500 Heavy Industry Thyristor CO2 MAG Gas Shielded Welding Machine MIG Welding Machine

- High current and voltage handling capabilities

- Low on-state voltage drop, reducing power loss

- Fast switching speeds for precise control

- Latching behavior: once triggered, remains conducting without continuous gate signal

- Robust and durable design suitable for harsh environments

- Available in various types (e.g., SCR, TRIAC, GTO) for specific needs

(KR-200/350/500 Heavy Industry Thyristor CO2 MAG Gas Shielded Welding Machine MIG Welding Machine)

Specifications of KR-200/350/500 Heavy Industry Thyristor CO2 MAG Gas Shielded Welding Machine MIG Welding Machine

The KR collection welding machines take care of heavy industrial jobs. They collaborate with CO2, MAG, and MIG processes. These are difficult machines built for requiring workshops. 3 versions exist: KR-200, KR-350, KR-500. The numbers reveal their power output in amps. Select the version matching your typical welding density and job needs.

All models utilize reliable thyristor control innovation. This gives secure welding arcs and regular efficiency. Power input is 3-phase 380V. This fits commercial settings. Outcome welding current adjusts across a vast array. The KR-200 provides 40-200 Amps. The KR-350 offers 60-350 Amps. The KR-500 delivers 100-500 Amps. Outcome voltage likewise adjusts for each and every version. This makes certain proper arc qualities for different products and cords.

Obligation cycle issues for continuous procedure. The KR-200 runs at 200A for 60% of a 10-minute cycle. The KR-350 performs at 350A for 60% task. The KR-500 handles 500A at 60% task. Greater task cycles mean much less downtime air conditioning. The devices utilize forced air cooling. Fans kick in instantly to stop getting too hot. Built-in thermal security includes security.

The devices are literally durable. Size enhances with power. The KR-200 measures around 700mm long, 400mm wide, 700mm high. Weight is about 150kg. The KR-350 is bigger, regarding 800mm long, 450mm vast, 750mm high. Weight nears 200kg. The KR-500 is the biggest, roughly 900mm long, 500mm vast, 800mm high. It considers concerning 250kg. They need sturdy positioning. Connection cords are conventional commercial length. Wire feeders are commonly sold individually.

(KR-200/350/500 Heavy Industry Thyristor CO2 MAG Gas Shielded Welding Machine MIG Welding Machine)

Applications of KR-200/350/500 Heavy Industry Thyristor CO2 MAG Gas Shielded Welding Machine MIG Welding Machine

This KR series welding device deals with laborious. It welds thick steel plates quickly. Construction websites need this power. Steel beam of lights and structures obtain solid welds quick. Shipyards rely upon devices similar to this. Structure big ship hulls and decks needs deep, solid welds. This machine delivers that power regularly. Pipe work is one more significant usage. Laying long oil and gas pipelines demands trustworthy welding. This equipment performs well outdoors. It stands up under stress. Automotive manufacturing facilities utilize these welders as well. Setting up truck frames and heavy lorry framework needs speed and penetration. This device provides both. Fixing hefty machinery is much easier with the KR series. Fixing broken components on building and construction equipment or farm devices requires a robust welder. This machine handles thick areas easily. The thyristor control offers constant current. This suggests less weld problems. Operators get smooth arcs. The maker deals with CO2 gas. It also makes use of MAG blends. This versatility matches various materials and work. It attaches to basic workshop power. Setting it up is uncomplicated. Workers find it reliable every day. Its develop quality fits demanding industrial environments. Manufacturing facilities appreciate its sturdiness. The regular outcome ensures quality welds whenever.

Company Profile

PDDN Photoelectron Technology Co., Ltd. is one of the leading enterprises in power electronics technology and power products, which is fully involved in developing solar inverters, transformers, voltage regulators, distribution cabinets, thyristors, modules, diodes, heaters, and other electronic devices or semiconductors. We will be committed to providing users with high-quality, efficient products and considerate service.

It accepts payment via Credit Card, T/T, West Union, and Paypal. PDDN will ship the goods to customers overseas through FedEx, DHL, by sea, or by air. If you want high-quality KR-200/350/500 Heavy Industry Thyristor CO2 MAG Gas Shielded Welding Machine MIG Welding Machine, please send us inquiries; we will be here to help you.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

Storage Conditions

1) Store in a dry environment at room temperature.

2) Avoid damp and high temperature.

3) Use immediately after opening the inner packing bag.

5 FAQs of KR-200/350/500 Heavy Industry Thyristor CO2 MAG Gas Shielded Welding Machine MIG Welding Machine

Here are 5 FAQs for the KR-200/350/500 Welding Machine:

What power supply does this machine need?

Check the specific model’s rating plate. The KR-200 often uses 220V single-phase. The larger KR-350 and KR-500 models usually need 380V three-phase power. Using the wrong voltage damages the machine. Always verify your workshop power matches the machine.

How thick metal can it weld?

The machine handles different thicknesses. The KR-200 welds steel up to about 8mm. The KR-350 handles up to 12mm. The KR-500 manages the thickest steel, up to around 20mm. Actual thickness depends on wire size and your welding technique.

What gas does it use?

This machine performs MAG/MIG welding with shielding gas. It uses CO2 gas alone. It also uses mixed gases like Argon/CO2. The gas type depends on the material and the weld quality you need. Always use the correct gas for your job.

Is this machine easy to move?

No, it’s heavy. The KR-200/350/500 are industrial machines built tough. They have sturdy frames and large transformers. They are designed for fixed workshop use. Moving them requires equipment like a forklift. They are not portable.

Does it need special maintenance?

Yes, basic care is essential. Keep the machine clean and dry. Dust and moisture cause problems. Regularly check wire feed rollers for wear. Inspect the welding torch cable and liner. Blow out dust from the inside with compressed air periodically. Good maintenance prevents breakdowns.

(KR-200/350/500 Heavy Industry Thyristor CO2 MAG Gas Shielded Welding Machine MIG Welding Machine)

REQUEST A QUOTE

RELATED PRODUCTS

Disc type KP series ordinary phase control thyristor / scr thyristor

Power Quality Device Advance Capacitor Controller Thyristor Switching Capacitor & Reactor Reactive Power Compensation Cabinet

Power Transistor Module;MOSFET;Triode;NPN/PNP Switch thyristor control;darlington GTR;RF power header drive application;inverter

High Power Silicon Controlled TRIAC THYRISTOR Modules BTA41 BTA26 BTA16 Packaged Power Drivers

Factory Direct BYKCS Series 10-50KVA Non-Contact Thyristor Switch 12V DC Common Causative Type