Electronic Components Supplier | Transformers, Inductors, Inverters

PRODUCT PARAMETERS

Description

Overview of Professional Arc Stud Welding Machine Thyristor Control for Large Projects IKING

Thyristor is a solid-state semiconductor device composed of four layers of alternating P- and N-type materials. It functions as a bistable switch, conducting current only when triggered by a gate signal, and remains conducting until the voltage across it drops below a certain threshold. Thyristors are widely used for controlling high-power electrical circuits, offering efficient and reliable performance in various industrial and electronic applications.

Features of Professional Arc Stud Welding Machine Thyristor Control for Large Projects IKING

- High current and voltage handling capabilities

- Low on-state voltage drop, reducing power loss

- Fast switching speeds for precise control

- Latching behavior: once triggered, remains conducting without continuous gate signal

- Robust and durable design suitable for harsh environments

- Available in various types (e.g., SCR, TRIAC, GTO) for specific needs

(Professional Arc Stud Welding Machine Thyristor Control for Large Projects IKING)

Specifications of Professional Arc Stud Welding Machine Thyristor Control for Large Projects IKING

The IKING Specialist Arc Stud Welding Equipment handles demanding massive building. Its innovative thyristor control makes certain specific power administration. This modern technology delivers consistent welding results every single time. Employees obtain reliable performance under tough conditions. The maker fits durable industrial applications.

It welds studs from 3mm to 25mm size. Steel, stainless-steel, aluminum materials work well. The system operates on 380V three-phase power. Input capability gets to 63A. This power sustains continuous high-output welding.

The control system includes automatic voltage settlement. Arc stability remains excellent despite input fluctuations. Operators change welding time and present quickly. Easy dial controls make settings straightforward.

Mobility issues for huge work sites. The portable design includes strong wheels. Moving in between work areas takes little effort. The machine stands up to dust and resonance.

Security precedes. The device has overload security. Thermal cutoffs avoid getting too hot. Anti-stick technology prevents stud jams. Basing faults set off instant shutdown.

Longevity is vital. The steel casing stands up to influences. Internal parts utilize industrial-grade components. Maintenance remains easy with accessible panels.

Devices include a 5m welding cable television and foot switch. The kit holds ten ceramic ferrules. A storage case keeps whatever arranged.

This welding machine tackles bridges, manufacturing facilities, high-rise buildings. Rate and dependability define its operation. Project managers depend on it for meeting target dates. Teams appreciate its straightforward style.

The IKING device outshines typical designs. Its engineering concentrates on real worksite demands. Productivity gains are prompt.

(Professional Arc Stud Welding Machine Thyristor Control for Large Projects IKING)

Applications of Professional Arc Stud Welding Machine Thyristor Control for Large Projects IKING

The IKING Professional Arc Stud Welding Maker utilizes thyristor control. This technology is crucial for large building and manufacturing tasks. It delivers accurate, powerful welding every time. Big jobs demand integrity. The thyristor control makes sure consistent welding current. This uniformity is crucial for solid, dependable stud connections. You obtain the exact same top quality weld repetitively, even over lengthy changes.

Consider developing tall structures like skyscrapers or bridges. Workers require to attach countless studs. These studs support concrete slabs or safe and secure heavy cladding panels. The IKING maker manages this hefty workload conveniently. Its accuracy prevents weak welds that can fall short later on. Shipyards use it thoroughly. It bonds studs onto ship decks and bulkheads. These studs hold back tools or assistance insulation systems. The extreme marine atmosphere requires ideal welds. The thyristor control supplies that.

Nuclear power plant and factories require stud welding too. It secures ductwork, cord trays, and hefty equipment bases. The device’s deep infiltration welds create bonds that manage vibration and hefty lots. Big storage facilities and commercial buildings rely on metal outdoor decking. This decking requirements many studs welded to steel beam of lights. The IKING maker quicken this process significantly. Its consistent power guarantees every stud bonds safely to the support framework. Time is money on huge sites. The device’s rate and dependability save both.

The IKING equipment is difficult. It works well sought after problems like dust, warmth, or cold. Its style concentrates on simplicity of usage for operators functioning long hours. Big tasks can not manage welding failings. The thyristor control minimizes errors. This control offers task managers confidence. They recognize the architectural links are done right the first time. Selecting the right tools matters for job success. The IKING Arc Stud Welding Device provides the required performance for large-scale, crucial applications.

Company Profile

PDDN Photoelectron Technology Co., Ltd. is one of the leading enterprises in power electronics technology and power products, which is fully involved in developing solar inverters, transformers, voltage regulators, distribution cabinets, thyristors, modules, diodes, heaters, and other electronic devices or semiconductors. We will be committed to providing users with high-quality, efficient products and considerate service.

It accepts payment via Credit Card, T/T, West Union, and Paypal. PDDN will ship the goods to customers overseas through FedEx, DHL, by sea, or by air. If you want high-quality Professional Arc Stud Welding Machine Thyristor Control for Large Projects IKING, please send us inquiries; we will be here to help you.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

Storage Conditions

1) Store in a dry environment at room temperature.

2) Avoid damp and high temperature.

3) Use immediately after opening the inner packing bag.

5 FAQs of Professional Arc Stud Welding Machine Thyristor Control for Large Projects IKING

What is this welding machine for?

It welds metal studs fast onto large structures like bridges or buildings. You need strong, permanent metal connections. This machine does that.

Why pick thyristor control?

Thyristor control gives you pinpoint accuracy every weld. It manages the power flow perfectly. You get consistent results project-wide. This matters for structural integrity.

Can it handle tough job sites?

Yes. It’s built for daily industrial use. The heavy-duty parts resist dust, vibration, and knocks. Reliability is key for big projects running long hours.

How many studs can it weld daily?

It’s made for high output. Expect hundreds of welds per shift easily. The powerful design supports continuous operation. Downtime hurts big schedules.

Are safety features included?

Absolutely. It has essential safeguards against electrical faults. Operator safety is critical. The controls are straightforward preventing mistakes. You work safer.

(Professional Arc Stud Welding Machine Thyristor Control for Large Projects IKING)

REQUEST A QUOTE

RELATED PRODUCTS

Foot Pedal Spot Welding Machine Thyristor Controller Resistor Welder Electrode Arm High Quality

Power Thyristor for Phase Control Triac Type

Disc type KP series ordinary phase control thyristor / scr thyristor

Power Quality Device Advance Capacitor Controller Thyristor Switching Capacitor & Reactor Reactive Power Compensation Cabinet

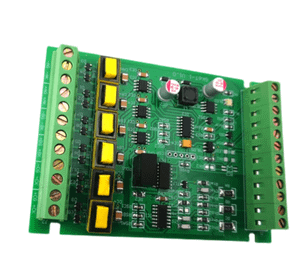

thyristor Control Board Ir thyristor Bridge Rectifier IRKT106/14