Electronic Components Supplier | Transformers, Inductors, Inverters

PRODUCT PARAMETERS

Description

Overview of SCR Thyristor Thyristor Rectifier for Induction Furnace Power Cabinet

Thyristor is a solid-state semiconductor device composed of four layers of alternating P- and N-type materials. It functions as a bistable switch, conducting current only when triggered by a gate signal, and remains conducting until the voltage across it drops below a certain threshold. Thyristors are widely used for controlling high-power electrical circuits, offering efficient and reliable performance in various industrial and electronic applications.

Features of SCR Thyristor Thyristor Rectifier for Induction Furnace Power Cabinet

- High current and voltage handling capabilities

- Low on-state voltage drop, reducing power loss

- Fast switching speeds for precise control

- Latching behavior: once triggered, remains conducting without continuous gate signal

- Robust and durable design suitable for harsh environments

- Available in various types (e.g., SCR, TRIAC, GTO) for specific needs

(SCR Thyristor Thyristor Rectifier for Induction Furnace Power Cabinet)

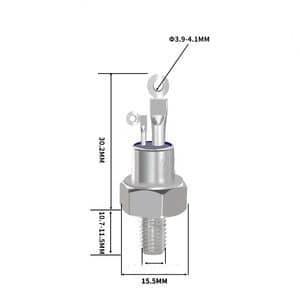

Specifications of SCR Thyristor Thyristor Rectifier for Induction Furnace Power Cabinet

This SCR Thyristor Rectifier powers induction furnace cabinets. It manages power. It provides stable melting. It works well for different metals.

The unit takes care of huge power tons. Input voltage is three-phase air conditioning. Typical levels are 380V, 415V, or 480V. Output is adjustable DC voltage. Output current is also flexible. This control is exact. Power variety is broad. It matches small and big furnaces.

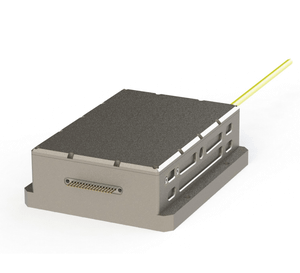

High-power SCR thyristors are the core. They switch over quick. They handle hefty currents. They are reputable. A strong heatsink cools them. Water air conditioning is basic. Air cooling benefit smaller sized systems. Cooling maintains temperature levels safe. This prevents damages.

Control is digital. A microprocessor takes care of whatever. It establishes outcome criteria. It keeps an eye on heating system conditions. Operators readjust setups conveniently. A regional panel shows information. Push-button control is feasible. Feedback loops maintain security. They react rapidly to adjustments.

Protection is integrated. It stops over-current. It stops over-voltage. It defends against under-voltage. It discovers stage loss. It enjoys temperature. Faults trigger closures. This secures the rectifier. It safeguards the furnace.

The rectifier fits inside the power cabinet. Its style is small. It conserves space. Links are clear. Circuitry is simple. Upkeep is easy. Access benefits service. The room is robust. It stands up to dust. It manages heat. Noise levels are low.

Dimensions depend on power rating. Weight likewise differs. Setup complies with conventional techniques. Placing factors are strong. It attaches to the heating system transformer. It incorporates with the cupboard controls. Compatibility is excellent.

(SCR Thyristor Thyristor Rectifier for Induction Furnace Power Cabinet)

Applications of SCR Thyristor Thyristor Rectifier for Induction Furnace Power Cabinet

SCR thyristor rectifiers are essential inside induction heater power cupboards. They handle the primary power work. These rectifiers change air conditioning power from the grid into DC power. This DC power is needed for the inverter area. The inverter after that develops the high-frequency air conditioner for melting steel inside the heater coil.

Power control is the biggest job. SCR thyristors act like extremely quick, solid switches. They change the DC voltage outcome precisely. This directly controls the power flowing into the heating system. You need this accurate control for different melting phases. Starting a cold cost needs a mindful approach. Keeping a complete thaw requirements steady, high power. SCRs allow drivers establish the exact power degree called for. They respond immediately to modifications.

Smooth power delivery matters. SCR rectifiers offer stable DC power. This stable DC helps the inverter work better. The outcome is consistent heating inside the heating system. Constant home heating suggests faster melting times. It additionally implies even more also temperature throughout the molten metal. This enhances total melting effectiveness.

Power cost savings are necessary. SCR thyristors handle power circulation smartly. They reduce thrown away energy throughout the conversion procedure. Effective power use reduces running prices. It also decreases the heating system’s influence on the electric supply system.

These rectifiers are constructed hard. They manage the requiring conditions of a melting store. They take care of high currents and voltages reliably day in day out. Their robust style guarantees the furnace maintains running. Downtime prices money. Reputable SCR rectifiers avoid unanticipated quits. They are a key part of a dependable induction melting system.

Company Profile

PDDN Photoelectron Technology Co., Ltd. is one of the leading enterprises in power electronics technology and power products, which is fully involved in developing solar inverters, transformers, voltage regulators, distribution cabinets, thyristors, modules, diodes, heaters, and other electronic devices or semiconductors. We will be committed to providing users with high-quality, efficient products and considerate service.

It accepts payment via Credit Card, T/T, West Union, and Paypal. PDDN will ship the goods to customers overseas through FedEx, DHL, by sea, or by air. If you want high-quality SCR Thyristor Thyristor Rectifier for Induction Furnace Power Cabinet, please send us inquiries; we will be here to help you.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

Storage Conditions

1) Store in a dry environment at room temperature.

2) Avoid damp and high temperature.

3) Use immediately after opening the inner packing bag.

5 FAQs of SCR Thyristor Thyristor Rectifier for Induction Furnace Power Cabinet

SCR thyristor rectifiers control power in induction furnace cabinets. They convert AC power. This becomes DC power. You need precise control for melting. These rectifiers manage that.

What is the main job? The rectifier changes incoming AC electricity. It makes smooth DC power. The induction furnace coils need this DC. It creates the strong magnetic field. That field melts metal efficiently. Thyristors act like fast switches. They adjust power flow exactly.

Why silicon-controlled rectifiers? Silicon handles high power well. It deals with the big currents and voltages furnaces demand. SCRs switch power fast. This gives precise control over the melting process. They are reliable under tough conditions. Other parts might fail faster.

How do they control power? The system uses a firing board. This board sends timing pulses. The pulses tell each thyristor when to turn on. Changing the pulse timing changes the power output. Later pulses mean less power goes to the furnace. This method adjusts heat accurately.

What causes overheating? Poor cooling is the main reason. SCRs generate significant heat during operation. Blocked air vents or failing pumps cause trouble. Dirty heatsinks trap heat. Electrical overloads stress the components. Good cooling is essential. Check water flow and fans regularly.

How do we maintain them? Keep the unit clean. Dust blocks cooling. Inspect electrical connections often. Loose connections overheat and fail. Monitor cooling systems constantly. Water flow and temperature matter most. Watch for warning signs like unusual noises or smells. Schedule professional checks yearly.

(SCR Thyristor Thyristor Rectifier for Induction Furnace Power Cabinet)

REQUEST A QUOTE

RELATED PRODUCTS

High Power Silicon Controlled TRIAC THYRISTOR Modules BTA41 BTA26 BTA16 Packaged Power Drivers

Three Phase Power Control Unit Thyristor (SCR Power Controller) Ramp / Soak Controllers

100 kw River Power Turbine Hydro Electric Generator

Stud Welding Machine

Thyristor driven optocoupler