Electronic Components Supplier | Transformers, Inductors, Inverters

PRODUCT PARAMETERS

Description

Overview of Ship Deck Flooring Shear Studs Connector Thyristor Stud Welding Machine

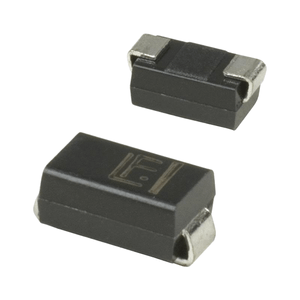

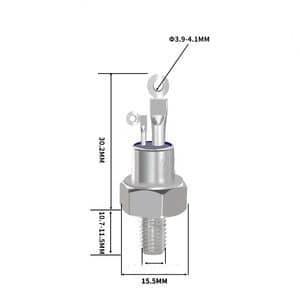

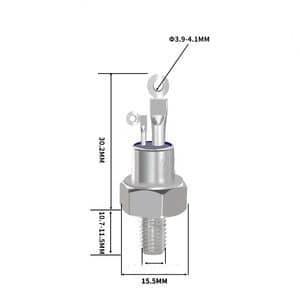

Thyristor is a solid-state semiconductor device composed of four layers of alternating P- and N-type materials. It functions as a bistable switch, conducting current only when triggered by a gate signal, and remains conducting until the voltage across it drops below a certain threshold. Thyristors are widely used for controlling high-power electrical circuits, offering efficient and reliable performance in various industrial and electronic applications.

Features of Ship Deck Flooring Shear Studs Connector Thyristor Stud Welding Machine

- High current and voltage handling capabilities

- Low on-state voltage drop, reducing power loss

- Fast switching speeds for precise control

- Latching behavior: once triggered, remains conducting without continuous gate signal

- Robust and durable design suitable for harsh environments

- Available in various types (e.g., SCR, TRIAC, GTO) for specific needs

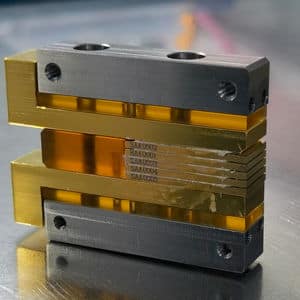

(Ship Deck Flooring Shear Studs Connector Thyristor Stud Welding Machine)

Specifications of Ship Deck Flooring Shear Studs Connector Thyristor Stud Welding Machine

This equipment welds shear stud adapters to deliver deck floor covering. It uses thyristor control innovation. This makes certain exact power distribution every weld. Constant power suggests strong, dependable connections. The stud welding procedure is quickly. It bonds studs to metal decks firmly. The bond stands up to heavy loads and harsh aquatic conditions.

The primary system houses the thyristor controller. This controller manages the welding current extremely properly. It adjusts instantaneously for various stud dimensions and product thicknesses. A sturdy welding weapon is included. The weapon driver holds it securely versus the deck. The stud feeder tons studs instantly. This speeds up the job significantly. Operators can weld several studs swiftly.

Efficiency is key. The equipment creates high-strength welds fulfilling marine standards. Penetration right into the base steel is deep. Bonded integrity is outstanding. This protects against studs from drawing loose under stress and anxiety. Ship decks encounter constant resonance and hefty freight. These welds hold company.

Safety functions secure the operator. The gun has a solid grip and security button. The system prevents accidental shooting. Electric parts are well-insulated. Grounding is critical. The device consists of a heavy-duty ground clamp. This makes certain a risk-free circuit course.

Setup is simple. Operators link power cables and the ground clamp. They load studs into the feeder. Changing setups is simple. Controls are clearly noted. Training is quick. Many operators discover the fundamentals quick.

Technical specifications cover important demands. Input power is generally 220V or 380V A/C. Single-phase or three-phase choices exist. Outcome welding current is high amperage. Duty cycle allows continuous operation. Stud size capacity ranges from smaller sized dimensions like 8mm to larger sizes like 22mm. Cable lengths are charitable. This provides excellent flexibility on the deck. The device is robustly developed. It manages difficult shipyard environments.

(Ship Deck Flooring Shear Studs Connector Thyristor Stud Welding Machine)

Applications of Ship Deck Flooring Shear Studs Connector Thyristor Stud Welding Machine

This machine welds metal studs to ship decks. It safeguards floor covering. The studs connect deck plates to beams. This avoids slipping. It strengthens the structure. The device utilizes thyristor control. This gives accurate power. It ensures consistent welds. Every stud bonds completely. Strong connections are essential. They manage heavy tons. They endure ocean forces. Ships face rough seas. Vibration is constant. Great welds last.

The equipment is mobile. Employees relocate easily. Shipyards are large spaces. Flexibility is important. Operators position it fast. They bonded studs quickly. This conserves labor time. Performance matters in building and construction. Hold-ups cost cash. The layout is difficult. It handles extreme environments. Salt air triggers rust. Dust is all over. The maker maintains functioning. Reliability avoids downtime.

It collaborates with different metals. Steel decks are common. Aluminum decks exist as well. The device adjusts setups. It bonds various stud dimensions. Various floor covering requires various studs. Density varies. The procedure is clean. Sparks are minimal. Fumes are lowered. Worker safety and security boosts. Shipyards are more secure locations.

The results are strong. The deck-floor bond is solid. Floor covering remains strongly connected. Staffs stroll safely. Devices stays steady. The ship handles much better. Structural stability increases. Safety and security mixed-up boosts. This welding is vital. Modern shipbuilding requires it. Quality connectors avoid failings.

Company Profile

PDDN Photoelectron Technology Co., Ltd. is one of the leading enterprises in power electronics technology and power products, which is fully involved in developing solar inverters, transformers, voltage regulators, distribution cabinets, thyristors, modules, diodes, heaters, and other electronic devices or semiconductors. We will be committed to providing users with high-quality, efficient products and considerate service.

It accepts payment via Credit Card, T/T, West Union, and Paypal. PDDN will ship the goods to customers overseas through FedEx, DHL, by sea, or by air. If you want high-quality Ship Deck Flooring Shear Studs Connector Thyristor Stud Welding Machine, please send us inquiries; we will be here to help you.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

Storage Conditions

1) Store in a dry environment at room temperature.

2) Avoid damp and high temperature.

3) Use immediately after opening the inner packing bag.

5 FAQs of Ship Deck Flooring Shear Studs Connector Thyristor Stud Welding Machine

This machine welds shear stud connectors onto ship decks. People have questions. Here are five common ones.

What exactly does this machine do? It attaches shear studs to metal decks fast. The studs connect the steel deck to the concrete flooring poured later. This creates a strong bond. The machine uses a thyristor-controlled electrical process. It makes very reliable welds.

How does the thyristor part help? The thyristor controls the welding current precisely. It turns the power on and off at the exact right moments. This ensures consistent weld quality every time. It prevents problems like weak welds or burning through the deck plate. Operators get dependable results.

Why pick this over other welding methods? This machine is much faster than manual welding. It also needs less operator skill for consistent results. The thyristor control guarantees each stud weld meets strength requirements. Speed and reliability are key advantages on big shipbuilding projects.

Who mainly uses these machines? Shipyards building large vessels are the primary users. Construction crews installing metal decks on offshore platforms also need them. Any project needing many strong, reliable shear stud welds fast benefits from this equipment.

What are the big benefits of using this machine? It drastically increases welding speed. Labor costs go down. Weld quality is consistently high and meets strict standards. The process is repeatable. Project timelines get shorter. Overall project costs are often lower.

(Ship Deck Flooring Shear Studs Connector Thyristor Stud Welding Machine)

REQUEST A QUOTE

RELATED PRODUCTS

High Productivity 400KG Induction Melting Furnace Electrical Thyristor Smelting Oven for Stainless Steel Iron Copper

Three Phase Power Control Unit Thyristor (SCR Power Controller) Ramp / Soak Controllers

Factory Thyristor SCR KK KP 300A 500A 800A 1000A 1200A 1500A 1800A 2000A High Quality Thyristor For

High Current Capacity SCR MTC30-160 Power Module Cheap Thyristor ICs

Thyristor Stud Welding Machine