Electronic Components Supplier | Transformers, Inductors, Inverters

PRODUCT PARAMETERS

Description

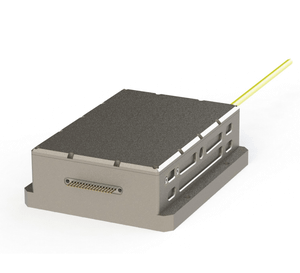

Overview of Stud Welding Machine

Thyristor is a solid-state semiconductor device composed of four layers of alternating P- and N-type materials. It functions as a bistable switch, conducting current only when triggered by a gate signal, and remains conducting until the voltage across it drops below a certain threshold. Thyristors are widely used for controlling high-power electrical circuits, offering efficient and reliable performance in various industrial and electronic applications.

Features of Stud Welding Machine

- High current and voltage handling capabilities

- Low on-state voltage drop, reducing power loss

- Fast switching speeds for precise control

- Latching behavior: once triggered, remains conducting without continuous gate signal

- Robust and durable design suitable for harsh environments

- Available in various types (e.g., SCR, TRIAC, GTO) for specific needs

(Stud Welding Machine)

Specifications of Stud Welding Machine

Stud welding equipments sign up with steel studs to surface areas swiftly and dependably. You require the appropriate specifications for your job. Power source matters most. Equipments run on typical air conditioning power, DC generators, or portable batteries. Examine the input voltage and frequency requires match your website. Output welding ability specifies what the maker takes care of. This suggests the stud diameter range it welds effectively. Typical machines handle studs from 2mm as much as 25mm or even more. The base steel thickness it can weld via is important as well. Thicker steels require more power.

Welding current and time control are necessary. Try to find flexible amperage setups. Precise control over the welding time cycle guarantees consistent, solid welds every time. Some models provide predetermined programs for usual stud dimensions. This simplifies procedure. Others offer complete hand-operated adjustment for seasoned customers. Take into consideration the duty cycle score. This informs you the length of time the equipment can weld continuously before needing a cool-down break. A higher duty cycle indicates much less waiting on busy jobs.

The machine consists of a welding weapon or gun. The cable length attaching the gun to the power device affects mobility. Longer wires provide even more reach. Safety features are non-negotiable. Automatic arc protecting secures the weld. Safety and security switches stop unintentional shooting. The system needs steady operation. Examine its weight and if it has wheels or manages for relocate around the worksite. Air conditioning systems maintain points running. Air air conditioning is common. Water cooling might be required for very durable, continuous use.

(Stud Welding Machine)

Applications of Stud Welding Machine

Stud welding makers attach metal studs to other surface areas quick and strong. They are important tools in numerous markets. Construction uses them regularly. Workers weld studs to steel beams and columns. They connect threaded studs for installing pipelines, ductwork, and electrical boxes. Steel outdoor decking obtains secured to structural steel with shear studs. This creates strong composite floors in structures. Panels and cladding call for studs for quick setup. Production counts greatly on stud welding. Automotive plants bonded studs onto cars and truck bodies. These studs hold circuitry harnesses, trim items, and insulation. Home appliance makers utilize them inside ovens, refrigerators, and washing devices. Studs provide accessory points for components and panels. The electronics market needs studs for basing and securing. Shipbuilding uses stud welding extensively. Decks obtain shear studs for concrete putting. Insulation pins weld straight to bulkheads and hulls. This saves time safeguarding products inside ships. Infrastructure projects gain from stud welding. Bridge building and construction utilizes shear connectors. These weld onto steel girders. Concrete then bonds to the steel for added toughness. Road signs attach to messages utilizing stud welding. The process is quickly on website. Repair work finds stud welding really helpful. Fixing devices often implies adding brand-new attachment points. Weld studs offer a solid remedy rapidly. The procedure functions well on existing structures. Stud welding devices deal with different stud dimensions and products. They work on steel, stainless steel, and aluminum. The bond is solid and reliable. It equals the stamina of the base metal. Speed is a major advantage. Operators mount numerous studs per hour. This effectiveness saves substantial labor time and expense. There is no demand for drilling openings. There is no requirement for punching holes either. This prevents deteriorating the base product. No bolts or rivets are called for. The result is a clean, flush accessory. The stud head welds straight to the surface area. This develops a smooth finish. Stud welding offers a functional, economical attaching method. It resolves many add-on difficulties across industries.

Company Profile

PDDN Photoelectron Technology Co., Ltd. is one of the leading enterprises in power electronics technology and power products, which is fully involved in developing solar inverters, transformers, voltage regulators, distribution cabinets, thyristors, modules, diodes, heaters, and other electronic devices or semiconductors. We will be committed to providing users with high-quality, efficient products and considerate service.

It accepts payment via Credit Card, T/T, West Union, and Paypal. PDDN will ship the goods to customers overseas through FedEx, DHL, by sea, or by air. If you want high-quality Stud Welding Machine, please send us inquiries; we will be here to help you.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

Storage Conditions

1) Store in a dry environment at room temperature.

2) Avoid damp and high temperature.

3) Use immediately after opening the inner packing bag.

5 FAQs of Stud Welding Machine

Stud welding joins metal studs to another metal surface quickly. It creates strong, permanent connections. Many industries rely on this method. Here are key questions people ask:

What exactly does a stud welding machine do? It uses electricity. The machine creates a powerful arc between the stud end and the base metal. This melts both surfaces. Then it pushes the stud into the molten pool. The metal cools fast. This forms a very strong weld. It’s much faster than drilling or tapping holes.

Where is stud welding typically used? It’s very common in construction. Workers attach steel studs to beams and columns. They secure decking and facades. Shipbuilding uses it for insulation and flooring. The automotive industry welds studs for wiring and parts. Any place needing strong, fast metal fastening benefits.

How does it work? First, load the stud into the welding gun. Position the gun firmly on the workpiece. Pull the trigger. The machine starts automatically. It lifts the stud slightly, creating the arc. The arc melts the stud tip and the base metal. The machine then plunges the stud into the molten pool. Pressure holds it until solid. The process takes only seconds per stud.

What safety features are important? Always wear protective gear. Use a welding helmet with the correct shade. Wear heavy gloves and fire-resistant clothing. Ensure the machine has proper grounding. Good ventilation is essential. Fumes from melting metal are hazardous. Keep the work area clear of flammables. Follow the machine’s specific safety instructions.

How much maintenance is needed? Regular checks keep it running well. Clean the gun and collet frequently. Metal spatter builds up. Check electrical connections for tightness. Replace worn parts like cables and tips. Lubricate moving parts as the manual says. Store the machine properly when not in use. Basic care prevents many problems.

(Stud Welding Machine)

REQUEST A QUOTE

RELATED PRODUCTS

High quality standard electronic components asymmetrical thyristor module thyristor control thyristor

Reactor Capacitor Thyristor Switched Capacitor Power Factor Capacitor Bank

200A 300V Thyristor Controlled Rectifier for Anodic Electrophoretic Coating

High Voltage Thyristor Control SCR kp1000A 1600V

Thyristor driven optocoupler