Electronic Components Supplier | Transformers, Inductors, Inverters

PRODUCT PARAMETERS

Description

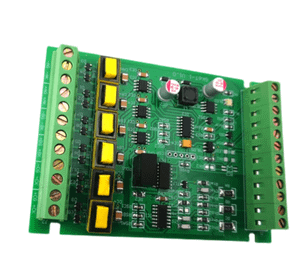

Overview of thyristor Control Board Ir thyristor Bridge Rectifier IRKT106/14

Thyristor is a solid-state semiconductor device composed of four layers of alternating P- and N-type materials. It functions as a bistable switch, conducting current only when triggered by a gate signal, and remains conducting until the voltage across it drops below a certain threshold. Thyristors are widely used for controlling high-power electrical circuits, offering efficient and reliable performance in various industrial and electronic applications.

Features of thyristor Control Board Ir thyristor Bridge Rectifier IRKT106/14

- High current and voltage handling capabilities

- Low on-state voltage drop, reducing power loss

- Fast switching speeds for precise control

- Latching behavior: once triggered, remains conducting without continuous gate signal

- Robust and durable design suitable for harsh environments

- Available in various types (e.g., SCR, TRIAC, GTO) for specific needs

(thyristor Control Board Ir thyristor Bridge Rectifier IRKT106/14)

Specifications of thyristor Control Board Ir thyristor Bridge Rectifier IRKT106/14

This thyristor control panel takes care of the IR thyristor bridge rectifier module IRKT106/14. It manages power circulation exactly. The setup is for converting air conditioning power into secure DC power. The IRKT106/14 component deals with heavy electric loads.

The IRKT106/14 rectifier itself is strong. It collaborates with voltages up to 1400 volts. It takes care of currents up to 106 amps constantly. This makes it helpful for industrial uses needing lots of power. Assume huge electric motor drives or electroplating systems.

The control board attaches straight to this rectifier component. It sends firing signals to the thyristors. This timing is critical. It determines specifically when each thyristor turns on during the air conditioning cycle. This timing control adjusts the DC result voltage smoothly. You obtain secure power also if the input voltage changes.

The board utilizes conventional control signals. These are commonly 0-10V DC or 4-20mA signals. This makes it simple to attach to existing systems. You established the wanted output level with this signal. The board does the intricate timing job.

Air conditioning is essential. The rectifier component needs a heatsink. Air or water cooling functions. Correct air conditioning prevents getting too hot. The system monitors temperature. It stops operation if things get as well hot. This protects the parts.

Electrical defense is consisted of too. The system spots brief circuits rapidly. It closes down power quickly if a mistake takes place. This quits damage. Overvoltage security is also typical. It defends against voltage spikes.

Installation is uncomplicated. The control board installs near the rectifier. Circuitry adheres to clear layouts. Configuration entails standard calibration. You adjust minimal and optimal output factors. The board handles the remainder immediately.

Reliability is a vital function. Industrial environments can be hard. This control panel and rectifier are built for them. They manage vibration and electric sound well. Maintenance is low. Just maintain it clean and check links occasionally. This makes it a trustworthy option for requiring DC power jobs.

(thyristor Control Board Ir thyristor Bridge Rectifier IRKT106/14)

Applications of thyristor Control Board Ir thyristor Bridge Rectifier IRKT106/14

This thyristor control panel handles the IRKT106/14 thyristor bridge rectifier. This arrangement converts air conditioner power into adjustable DC power. Think about it like a really exact, heavy-duty power valve. The control board tells the thyristors exactly when to switch on and off throughout each air conditioner cycle. This timing control straight alters the DC result voltage level. You obtain smooth, constant adjustment from absolutely no up to virtually the complete input voltage.

The IRKT106/14 rectifier itself is developed tough. It uses high-power thyristor components recognized for managing big currents and high voltages dependably. This certain version prevails in industrial applications requiring durable DC power control. The control panel incorporates flawlessly with it. The board monitors the AC input. It additionally checks the DC outcome. It sends out specific shooting pulses to the thyristors based on your setups. This makes certain secure DC result even if the AC input changes or the load adjustments suddenly.

This mix succeeds where you need precise electric motor rate control. Large DC motors in mills, extruders, or paper equipments use this modern technology. It offers the variable DC voltage important for smooth acceleration, deceleration, and keeping continuous speed under differing loads. It’s likewise vital in electroplating and electrolysis processes. Here, keeping an extremely constant, details DC current is important for product quality. The thyristor bridge delivers this dependably. One more key usage remains in commercial DC welding power products. The control permits fine-tuning of the welding existing for various jobs and products.

The system offers high effectiveness. It loses minimal power as heat compared to older approaches. This conserves power prices, specifically in continuous procedure. The thyristor control is very receptive. It adjusts the result practically immediately to match command signals or tons changes. This rapid reaction prevents motor delaying or process interruptions. Integrated protections are standard. The control board detects mistakes like overloads, short circuits, or overheating. It shuts down the thyristors swiftly to protect both the rectifier and your devices. This dependability makes it a favored service for requiring industrial settings.

Company Profile

PDDN Photoelectron Technology Co., Ltd. is one of the leading enterprises in power electronics technology and power products, which is fully involved in developing solar inverters, transformers, voltage regulators, distribution cabinets, thyristors, modules, diodes, heaters, and other electronic devices or semiconductors. We will be committed to providing users with high-quality, efficient products and considerate service.

It accepts payment via Credit Card, T/T, West Union, and Paypal. PDDN will ship the goods to customers overseas through FedEx, DHL, by sea, or by air. If you want high-quality thyristor Control Board Ir thyristor Bridge Rectifier IRKT106/14, please send us inquiries; we will be here to help you.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

Storage Conditions

1) Store in a dry environment at room temperature.

2) Avoid damp and high temperature.

3) Use immediately after opening the inner packing bag.

5 FAQs of thyristor Control Board Ir thyristor Bridge Rectifier IRKT106/14

FAQs: Thyristor Control Board IRKT106/14 Thyristor Bridge Rectifier

What does the IRKT106/14 Thyristor Rectifier do?

This unit controls large amounts of electrical power. It converts AC voltage into adjustable DC voltage. The thyristor control board manages the switching of the thyristors. This allows precise control over the output power level.

Where is this rectifier typically used?

It powers heavy industrial equipment. Common applications include DC motor drives for large machines. It works well in electroplating systems requiring controlled current. It also serves in battery charging stations for industrial batteries. Power supplies for electrolysis processes use this type of rectifier too.

How do I install the IRKT106/14?

Installation requires a qualified electrician. Mount the unit securely on a suitable surface. Ensure proper cooling airflow around the heatsink. Connect the AC power input correctly to the specified terminals. Wire the DC output terminals to your load carefully. Follow the manufacturer’s wiring diagram exactly.

What safety precautions are important?

This equipment uses high voltage and current. Handle it only with power completely disconnected. Verify zero voltage before touching any terminals. Use appropriate personal protective equipment (PPE). Never bypass safety interlocks or fuses. Ensure the equipment is properly grounded. Only trained personnel should operate or maintain it.

What causes common failures?

Overheating damages thyristors and control boards. Check cooling fans and heatsinks for dirt or blockage. Power surges or voltage spikes harm components. Use proper surge protection devices. Loose electrical connections create heat and failure points. Tighten all terminal connections securely. Contaminants like dust or moisture cause short circuits. Keep the unit clean and dry. Control board issues sometimes stem from faulty sensors or wiring.

(thyristor Control Board Ir thyristor Bridge Rectifier IRKT106/14)

REQUEST A QUOTE

RELATED PRODUCTS

In Stock Three Phase Digital Thyristor Power Regulator for Electric Heating 100a 200a 300a

Reactor Capacitor Thyristor Switched Capacitor Power Factor Capacitor Bank

Competitive Thyristor Switch Control Thyristor Dynamic Switching Switches

Regulator for Controlled Rectifier Circuit Thyristor Manufacturing Wind Generators and Resistance Welders Companies

Whole Three Phase Energy Regulator 400V SCR Thyristor Voltage Stabilizer Regulator