Electronic Components Supplier | Transformers, Inductors, Inverters

PRODUCT PARAMETERS

Description

Overview of Thyristor for Induction Furnace

Thyristor is a solid-state semiconductor device composed of four layers of alternating P- and N-type materials. It functions as a bistable switch, conducting current only when triggered by a gate signal, and remains conducting until the voltage across it drops below a certain threshold. Thyristors are widely used for controlling high-power electrical circuits, offering efficient and reliable performance in various industrial and electronic applications.

Features of Thyristor for Induction Furnace

- High current and voltage handling capabilities

- Low on-state voltage drop, reducing power loss

- Fast switching speeds for precise control

- Latching behavior: once triggered, remains conducting without continuous gate signal

- Robust and durable design suitable for harsh environments

- Available in various types (e.g., SCR, TRIAC, GTO) for specific needs

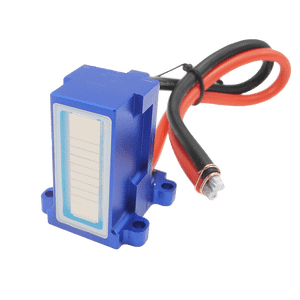

(Thyristor for Induction Furnace)

Specifications of Thyristor for Induction Furnace

Thyristors power induction furnaces. They switch high currents fast. This controls the furnace heating precisely. These devices must handle tough conditions. Key specifications are vital.

Voltage rating matters most. The thyristor’s peak repetitive reverse voltage (Vrrm) and peak off-state voltage (Vdrm) must exceed the furnace circuit’s maximum voltage. This prevents breakdown. Current rating is equally critical. The thyristor’s average on-state current (Itav) and surge current (Itsm) must manage the furnace’s normal and peak loads. Undersizing causes failure.

Heat is a major enemy. Thyristors get very hot switching large currents. The case temperature must stay below its maximum rating (Tc). Proper heatsinking is non-negotiable. Thermal resistance (Rth j-c) defines how well heat moves from the silicon to the case. A low value is better. Good cooling systems are essential.

Switching speed affects efficiency. Turn-on time (ton) and turn-off time (tq) need to be fast. This minimizes power loss during switching. Snubber circuits are often used. They protect the thyristor from dangerous voltage spikes during turn-off.

The gate drive needs precision. The thyristor requires a specific gate trigger current (Igt) and voltage (Vgt) to turn on reliably. Gate power limits (Pg) must not be exceeded. Good gate control ensures stable operation. Isolation between gate and main terminals is mandatory for safety and control. Protection features like overcurrent and overvoltage detection are strongly recommended. They prevent damage from unexpected faults.

(Thyristor for Induction Furnace)

Applications of Thyristor for Induction Furnace

Thyristors control power in induction furnaces. They switch large electrical currents fast. This switching manages the furnace temperature precisely. Precise temperature control is vital for melting metals. Thyristors act like strong, fast switches inside the power electronics. They turn the power feeding the furnace coils on and off very quickly.

This fast switching adjusts the power level sent to the furnace. Operators change the power setting. The thyristors respond instantly. This control keeps the metal melting at the exact right temperature. Consistent temperature makes good quality metal. It also saves energy.

Thyristors also help change the electrical frequency. Induction furnaces need specific frequencies to work well. Different metals need different frequencies. Thyristor circuits take standard power line frequency. They convert it to the high frequency the furnace needs. This conversion is efficient.

Thyristors are tough electronic parts. They handle the huge electrical currents and voltages in furnaces. Furnaces run for many hours melting metal. Thyristors keep working reliably under this stress. This reliability means less furnace downtime.

Using thyristors allows building very big furnaces. They manage the massive power demands. Modern induction furnaces depend on thyristor technology. They provide the control, efficiency, and power handling required. This makes the melting process effective.

Company Profile

PDDN Photoelectron Technology Co., Ltd. is one of the leading enterprises in power electronics technology and power products, which is fully involved in developing solar inverters, transformers, voltage regulators, distribution cabinets, thyristors, modules, diodes, heaters, and other electronic devices or semiconductors. We will be committed to providing users with high-quality, efficient products and considerate service.

It accepts payment via Credit Card, T/T, West Union, and Paypal. PDDN will ship the goods to customers overseas through FedEx, DHL, by sea, or by air. If you want high-quality Thyristor for Induction Furnace, please send us inquiries; we will be here to help you.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

Storage Conditions

1) Store in a dry environment at room temperature.

2) Avoid damp and high temperature.

3) Use immediately after opening the inner packing bag.

5 FAQs of Thyristor for Induction Furnace

What is a thyristor?

A thyristor is a powerful electronic switch. It controls large amounts of electrical power. Think of it like a very strong gate for electricity. Once triggered, it lets current flow until the power stops.

Why use thyristors in induction furnaces?

Induction furnaces need precise power control. Thyristors handle this job perfectly. They switch the furnace current on and off very fast. This precise switching creates the magnetic field needed to melt metal. Other switches aren’t fast enough or powerful enough.

What are the main benefits?

Thyristors offer excellent control over furnace power. This leads to better temperature accuracy. They are very efficient, wasting little energy as heat. Their fast switching enables smooth furnace operation. This control improves melting quality and saves energy.

What causes thyristors to fail?

Overheating is the biggest problem. Poor cooling or blocked airflow causes this. Power surges or voltage spikes can destroy them instantly. Electrical noise interfering with the trigger signal causes misfiring. Old age and wear eventually lead to failure too.

How do we maintain them?

Keeping thyristors cool is critical. Check fans and cooling systems work right. Clean air filters and heat sinks regularly. Ensure electrical connections stay tight and clean. Monitor voltage and current levels stay within limits. Use protection devices against surges. Check trigger circuits for noise. Replace units showing signs of wear early.

(Thyristor for Induction Furnace)

REQUEST A QUOTE

RELATED PRODUCTS

Induction Foundry Pouring Melting Furnace Industrial for Casting Steel Iron Machine

Three Phase Power Bridge Rectifier Thyristor Diode IGBT MODULE

FUSE IGBT THYRISTOR DIODE

thyristor SCR thyristor cheap

KR-200/350/500 Heavy Industry Thyristor CO2 MAG Gas Shielded Welding Machine MIG Welding Machine