Electronic Components Supplier | Transformers, Inductors, Inverters

PRODUCT PARAMETERS

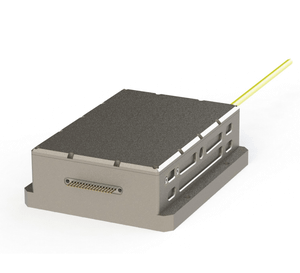

Description

Overview of Thyristor Switch Control Thyristor Dynamic Switching Switches

Thyristor is a solid-state semiconductor device composed of four layers of alternating P- and N-type materials. It functions as a bistable switch, conducting current only when triggered by a gate signal, and remains conducting until the voltage across it drops below a certain threshold. Thyristors are widely used for controlling high-power electrical circuits, offering efficient and reliable performance in various industrial and electronic applications.

Features of Thyristor Switch Control Thyristor Dynamic Switching Switches

- High current and voltage handling capabilities

- Low on-state voltage drop, reducing power loss

- Fast switching speeds for precise control

- Latching behavior: once triggered, remains conducting without continuous gate signal

- Robust and durable design suitable for harsh environments

- Available in various types (e.g., SCR, TRIAC, GTO) for specific needs

(Thyristor Switch Control Thyristor Dynamic Switching Switches)

Specifications of Thyristor Switch Control Thyristor Dynamic Switching Switches

Thyristor Switch Control systems manage power flow in demanding applications. These systems use thyristors as solid-state switches. They turn power on and off very quickly. This speed is critical for managing dynamic loads. Switching happens in milliseconds. This prevents voltage drops and flicker.

The control unit is the system’s brain. It sends precise signals to the thyristors. This tells them exactly when to switch. Operators set parameters using the controller. They adjust switching times and patterns. The controller monitors voltage and current constantly. It ensures the thyristors switch at the perfect moment. This protects equipment downstream.

The thyristors themselves handle high currents. They are rated for specific voltage levels. Common ratings include 1200V, 1700V, or higher. Current ratings often reach hundreds or thousands of amps. These components are built tough. They withstand electrical stress and surges. Proper cooling is essential. Heat sinks or fans prevent overheating. This maintains reliable operation.

Protection features are built-in. The system watches for problems. It detects overcurrent and short circuits instantly. It also guards against overvoltage events. If a fault happens, the system reacts immediately. It shuts down the thyristors safely. This prevents damage to the switch and connected devices. Status indicators show system health. Alarms signal any issues needing attention.

The switching logic is flexible. It handles different load types effectively. Systems manage resistive loads like heaters. They also control inductive loads like motors. Reactive power compensation is a key application. The thyristors switch capacitor banks rapidly. This stabilizes the power factor. It improves overall electrical efficiency.

(Thyristor Switch Control Thyristor Dynamic Switching Switches)

Applications of Thyristor Switch Control Thyristor Dynamic Switching Switches

Thyristor Switch Control devices manage power flow using special semiconductor switches. These switches handle high power levels. They switch very fast. This makes them useful for many applications.

Factories use these thyristor switches to control big electric motors. They adjust motor speed smoothly. This saves energy. Machines last longer. Production improves. Power grids also depend on these switches. They manage electricity flow across long distances. They connect or disconnect power sources quickly. This keeps voltage stable. Blackouts are prevented.

Renewable energy systems need thyristor dynamic switching. Solar panels and wind turbines produce changing power. These switches handle that variable power. They feed it efficiently into the grid. Power quality stays good. Lighting systems use them too. They dim bright lights like street lamps. This cuts electricity use. Maintenance costs drop.

Transportation systems rely on thyristor control. Electric trains and trams need precise power control. These switches deliver it. They manage acceleration and braking smoothly. Riders experience comfortable journeys. Power electronics in general use thyristor switches. They convert power types. They regulate voltage. They protect circuits from damage. Devices work reliably.

Company Profile

PDDN Photoelectron Technology Co., Ltd. is one of the leading enterprises in power electronics technology and power products, which is fully involved in developing solar inverters, transformers, voltage regulators, distribution cabinets, thyristors, modules, diodes, heaters, and other electronic devices or semiconductors. We will be committed to providing users with high-quality, efficient products and considerate service.

It accepts payment via Credit Card, T/T, West Union, and Paypal. PDDN will ship the goods to customers overseas through FedEx, DHL, by sea, or by air. If you want high-quality Thyristor Switch Control Thyristor Dynamic Switching Switches, please send us inquiries; we will be here to help you.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

Storage Conditions

1) Store in a dry environment at room temperature.

2) Avoid damp and high temperature.

3) Use immediately after opening the inner packing bag.

5 FAQs of Thyristor Switch Control Thyristor Dynamic Switching Switches

Here are five common questions about Thyristor Switch Control (TSC) Thyristor Dynamic Switching Switches:

What do thyristor dynamic switching switches actually do? They control power flow in electrical systems. They switch capacitor banks on and off very fast. This manages reactive power. Good reactive power control keeps voltage stable. It also improves power factor. Better power factor saves money. It reduces wasted energy.

Why use thyristors instead of regular contactors? Speed is the big reason. Thyristors switch incredibly fast. Think milliseconds. Mechanical contactors are much slower. Fast switching means precise control. Precise control prevents voltage spikes. It avoids flickering lights. It protects sensitive equipment. This smooth operation is critical.

How does this help with reactive power compensation? Capacitors generate reactive power. Systems need just the right amount. Too much or too little causes problems. Thyristor switches add or remove capacitor banks instantly. They react to changes in the load immediately. This keeps the reactive power balanced perfectly. Balanced reactive power makes the whole system run efficiently.

Are these switches reliable? Yes, they are very reliable. They have no moving parts to wear out. Mechanical contactors use springs and contacts. These can fail over time. Thyristors are solid-state electronics. They handle millions of switching operations. They need minimal maintenance. This means less downtime. Less downtime saves costs.

Do they need special maintenance? They need very little maintenance. Check the cooling system regularly. Fans or heatsinks must stay clean. Dust buildup causes overheating. Overheating damages the thyristors. Monitor the control electronics occasionally. Look for error signals. Basic visual inspections are usually enough. Follow the manufacturer’s specific schedule.

(Thyristor Switch Control Thyristor Dynamic Switching Switches)

REQUEST A QUOTE

RELATED PRODUCTS

Metal Table Lamp Touch Switch Module AC110V-220V LED Incandescent Bulb Thyristor Dimming ON-OFF High Tension Touch Switch

FUSE IGBT THYRISTOR DIODE

High quality standard electronic components asymmetrical thyristor module thyristor control thyristor

Factory Direct Premium Quality 100mm/120mm Toroidal Nanocrystalline Transformer Soft Iron Core Common Mode Choke

Medium Frequency Induction Heating Metal Pipe Furnace